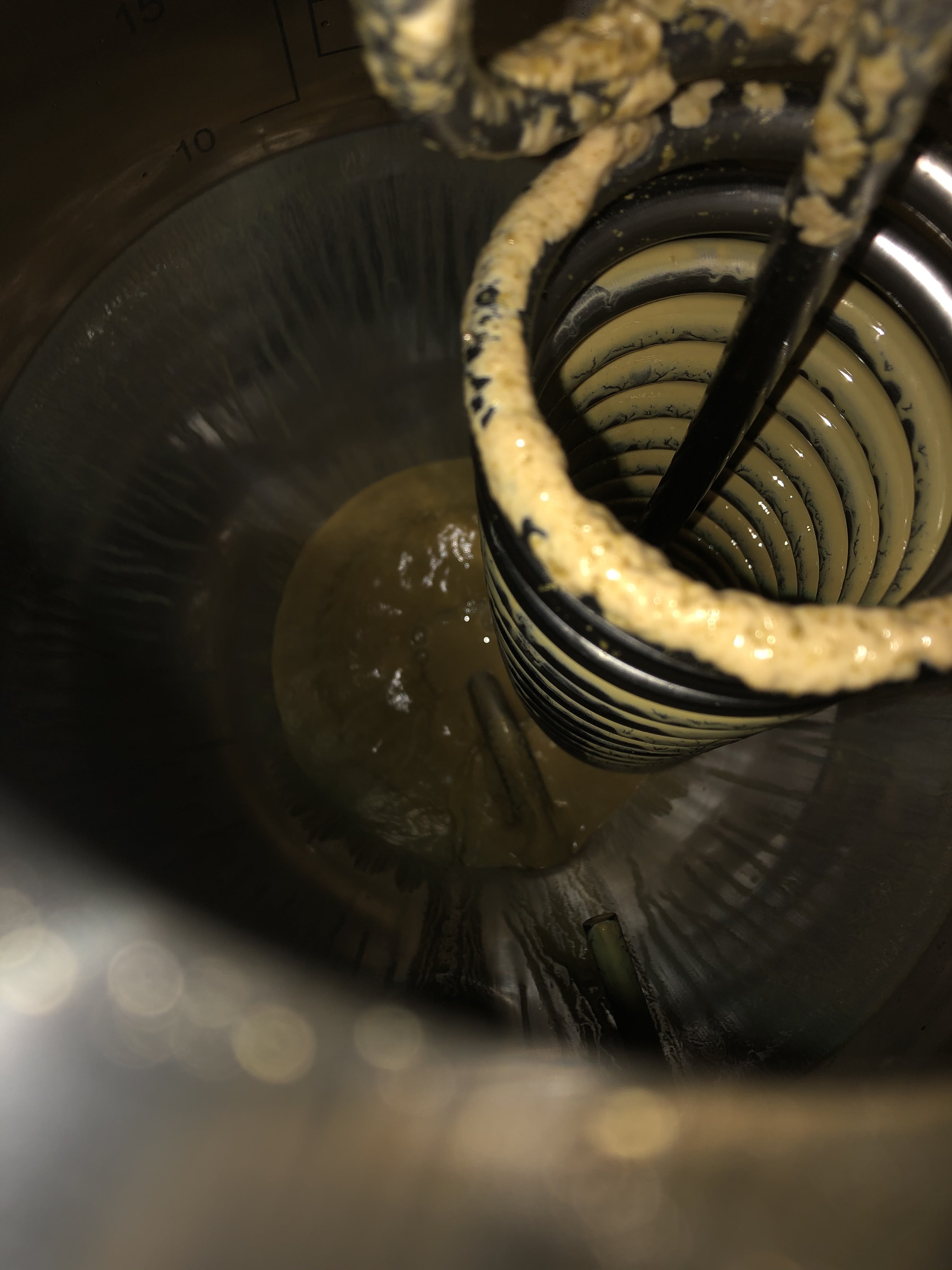

Just a curious question, but is there anyone here who don't/can't cold crash their conicals? I have an IPA in my CF10 and and plan on a dry hop. The last time, I bagged the hops and it clogged my racking arm. I may just see about tying off the bag to let it hang, but if just tossing the hops in commando is better I'll go that route. Just thought I'd ask first.

Planning on an ounce each of Centennial, Simcoe, and Columbus.

3 ounce total in a cf10? Even with 5 gallons (i assume 10) i would say use the racking arm. Throw thoose boys in commando!!! That way you will get maximim extraction and can still draw clear beer.

My $0.02.