My Goldbergian vents are 6" galvy ducting to the blower which then fires into a ~2 foot long 3.25" x 10" galvy section in the overhang space under the second story floor, then exits downwards once outside. And before anyone gets the vapors the whole thing is positioned behind the kettles so even if it did drip the drips will miss the kettles.

Anyway it worked fairly well for its maiden run but not without issue. I quickly found I needed a way to balance the flow between the BK and HLT drops during the brewing liquor pre-boiling, which I split between the two kettles for the sake of speed. With two 90° turns to the HLT vs a straight shot to the BK almost all the flow was through the latter, and the thus uncontained heat plume from the HLT rose straight up and caused the blower to thermal shutdown. Fun!

I did the NASCAR thing and put some tape across the BK duct to get through the day and from that point the system worked very well.

This week I added a pair of dampers that allow me to fully control air flow now. I'm brewing another batch tomorrow so I'll be giving it a full test.

My original intention was to fab a hood - and I may still do that. I had used the blower and the 6" stuff in my shop when I brewed in there and at least to this point was considered temporary. But it works so well I may just stick with it because I see a lot of problems folks have with hoods...

Cheers!

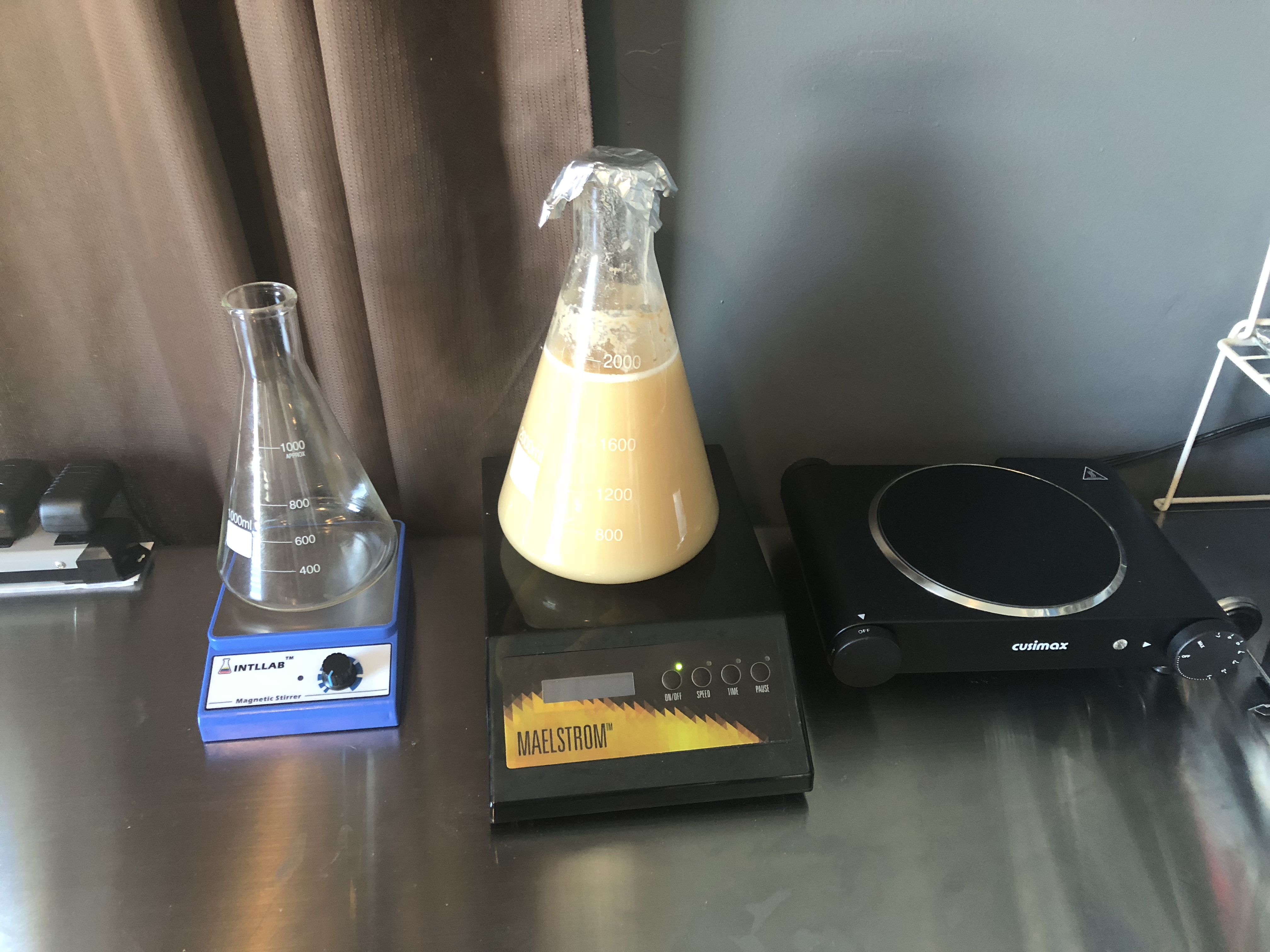

![20180324_205023[1].jpg 20180324_205023[1].jpg](https://cdn.homebrewtalk.com/data/attach/504/504181-20180324-205023-1-.jpg)