Thoughts?

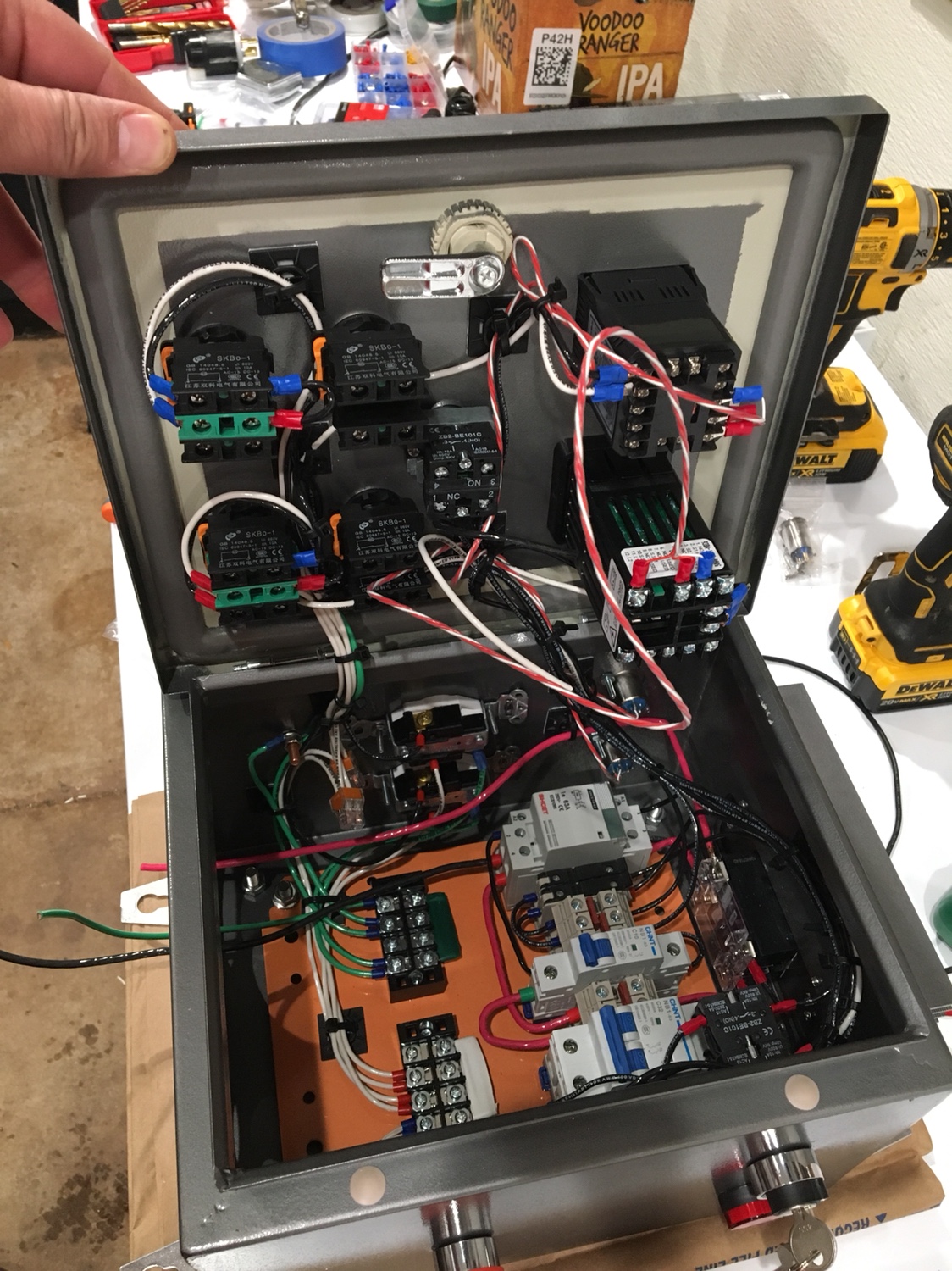

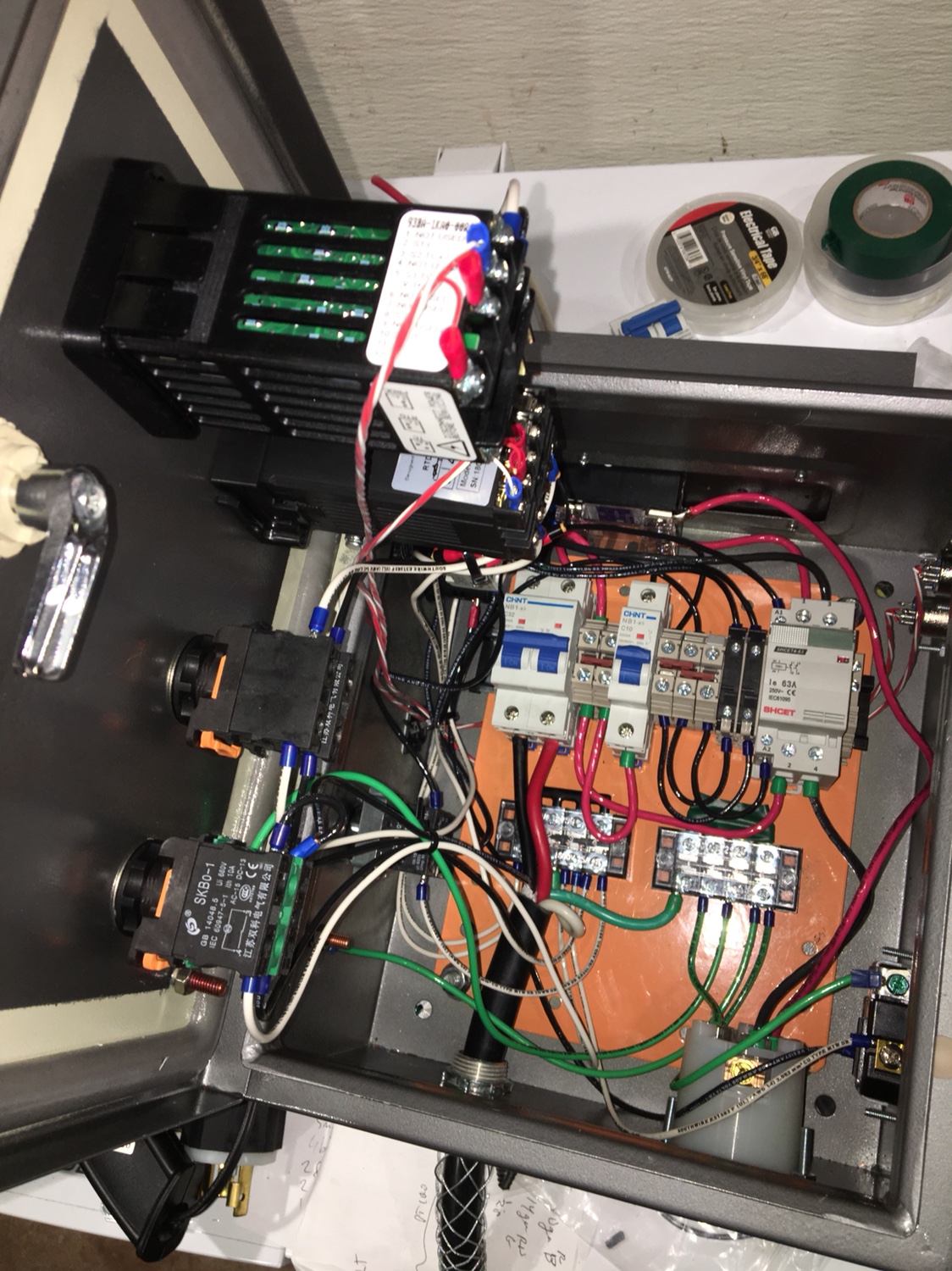

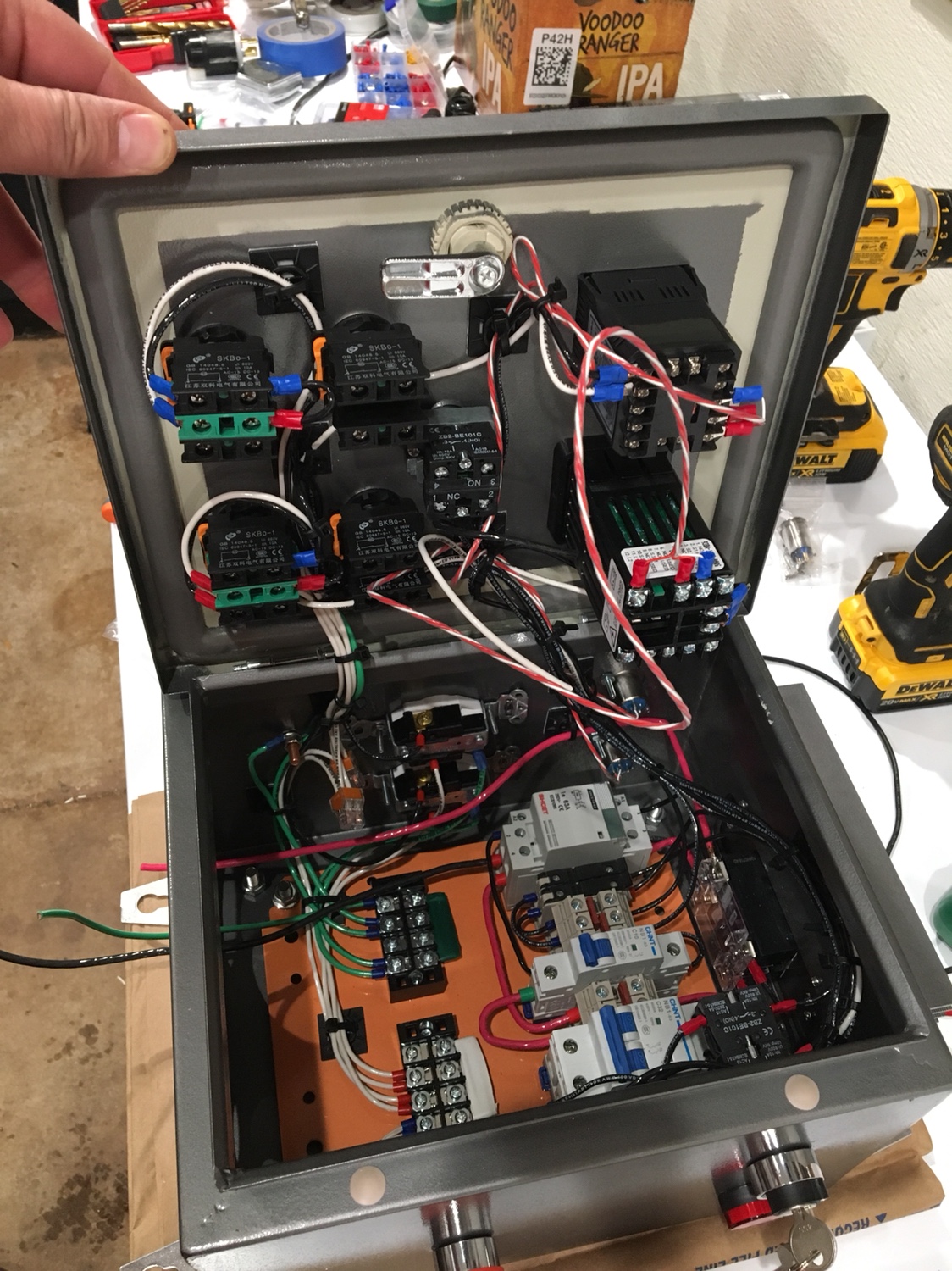

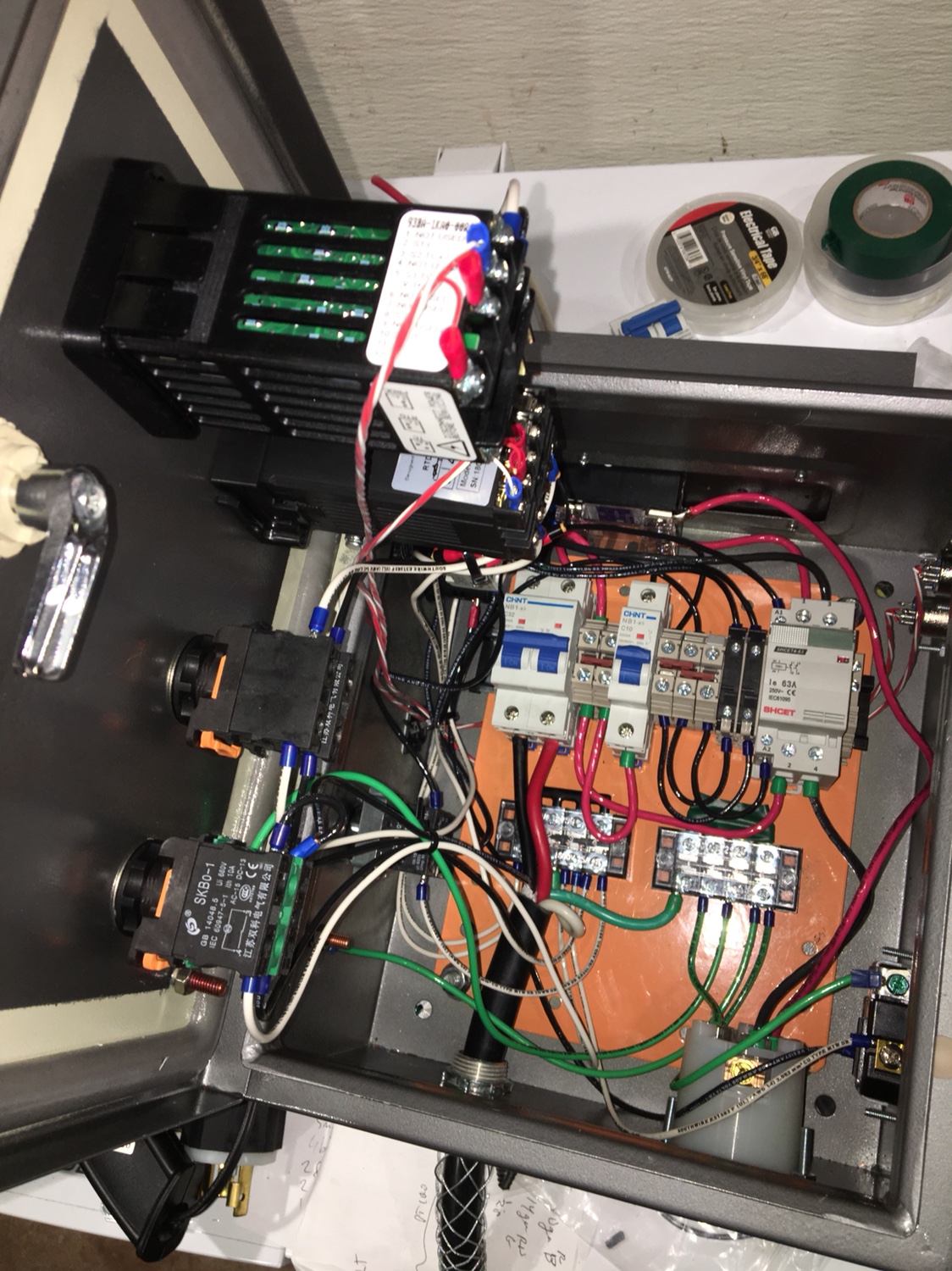

I just built 2 control boxes with one each and ended up getting 2 more ezboils to replace the Watlows I initially installed as the the 2nd PID in each box...

The ezboils are super ez to program. But haven’t tested either with water yet.

View attachment 601107

I just built 2 control boxes with one each and ended up getting 2 more ezboils to replace the Watlows I initially installed as the the 2nd PID in each box...

The ezboils are super ez to program. But haven’t tested either with water yet.

View attachment 601107