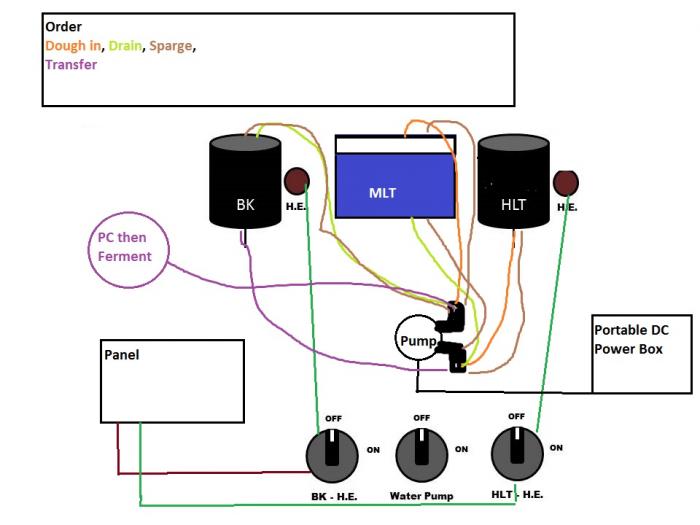

I am thinking of going into electric brewing as it's more cost efficient. I want a simple control panel:

two elements, on/off switches for each, that's it.

Pump is DC so not needed. I have thermometers and eyes so I don't need electronic controls and alarms.

How simple is this to make and has anyone made one (cost?)?

two elements, on/off switches for each, that's it.

Pump is DC so not needed. I have thermometers and eyes so I don't need electronic controls and alarms.

How simple is this to make and has anyone made one (cost?)?