Carlscan26

Well-Known Member

I certainly do! Unless I'm trying to brew a small beer[emoji6]

Can you provide detail on your control panel?

I certainly do! Unless I'm trying to brew a small beer[emoji6]

Can you provide detail on your control panel?

Only about as well as any electrical retard can.. Here's the part I remember and understand: It's 240v, I have 4500 watt elements...because I was impatient and didn't want to ship myself the 5500w ripp elements.. It's the v3 from high gravity, of course the came out with a 50 amp version about 6 months after I bought this one...which runs about 30? Or 28? At startup.. Haven't done the math in a while... Otherwise, locking plugs, spa panel from home depot, PIDs and I love it. I can't read a wiring diagram

but I can cook like a Martha focker so I just bought it from them.

Ps, they have great customer service and fast shipping. Plus, semi automation is really nice.

This was an easy and very mobile stand project. Two platforms sized to fit specific location. Just use clamps to secure but those are not really needed due to the taper of the ladder keeping the platform from tipping. I put hooks on the side for mash paddle and spoon. Breaks down in a jiffy and packs well for storage. Cheers!

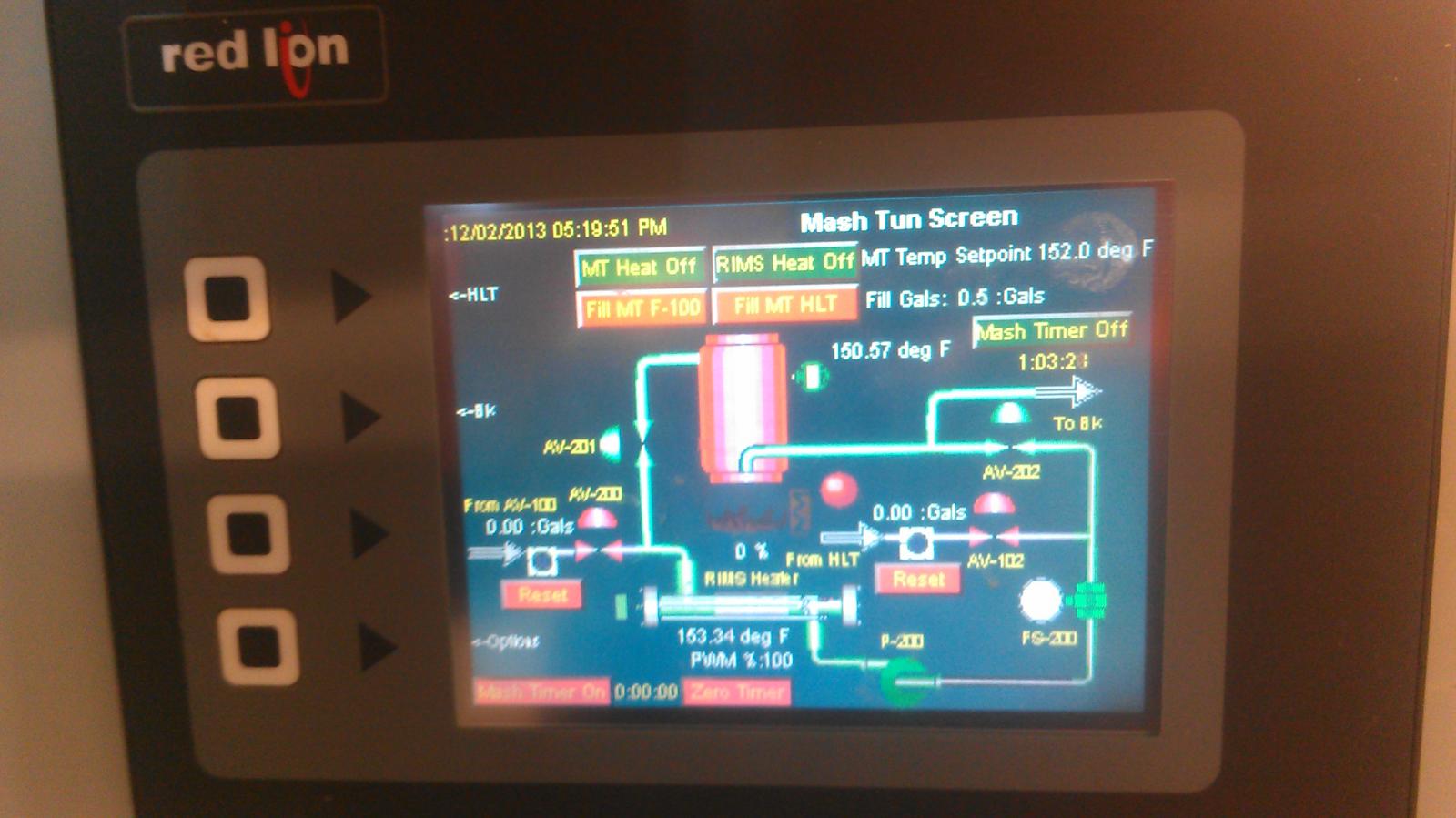

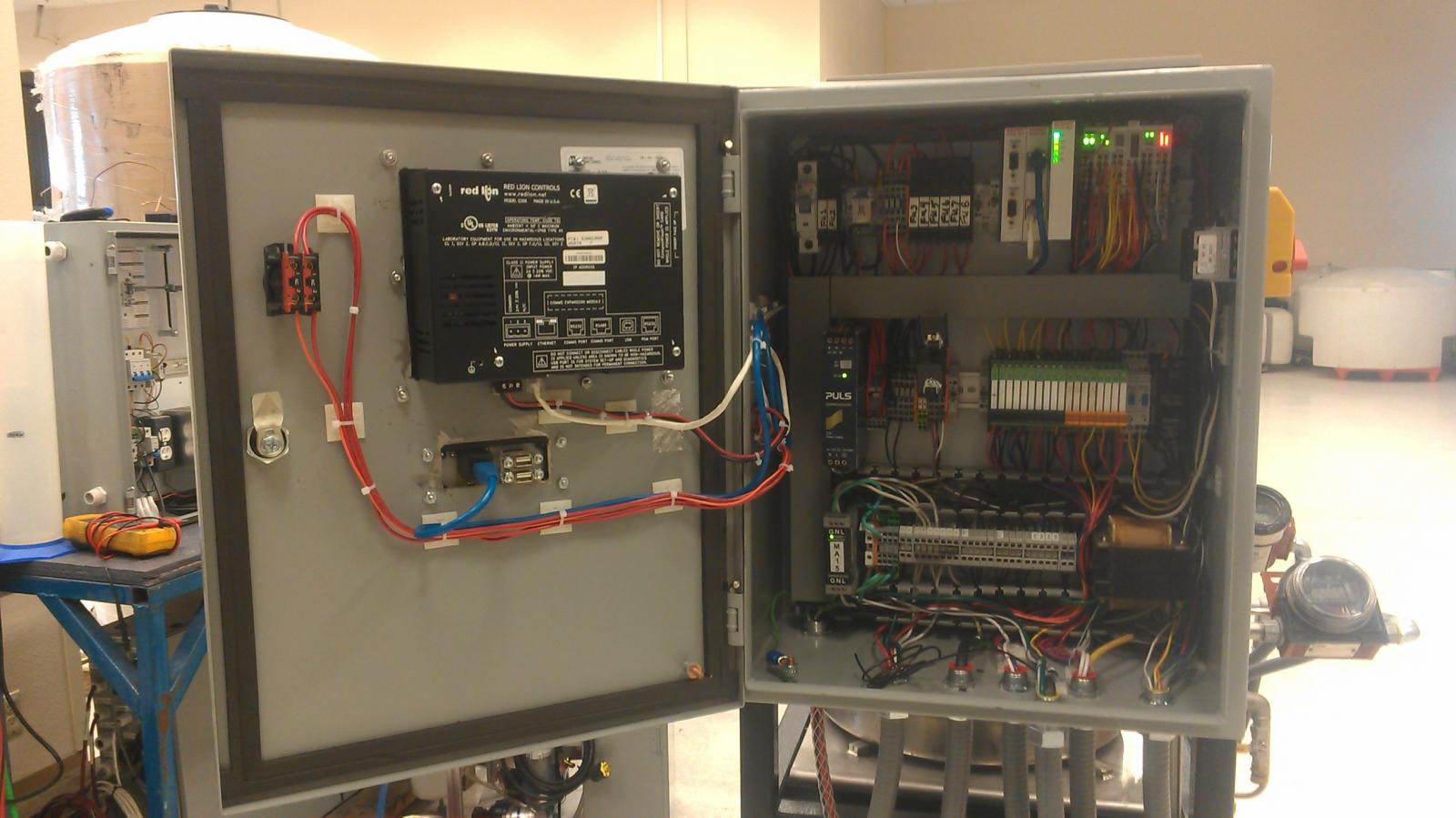

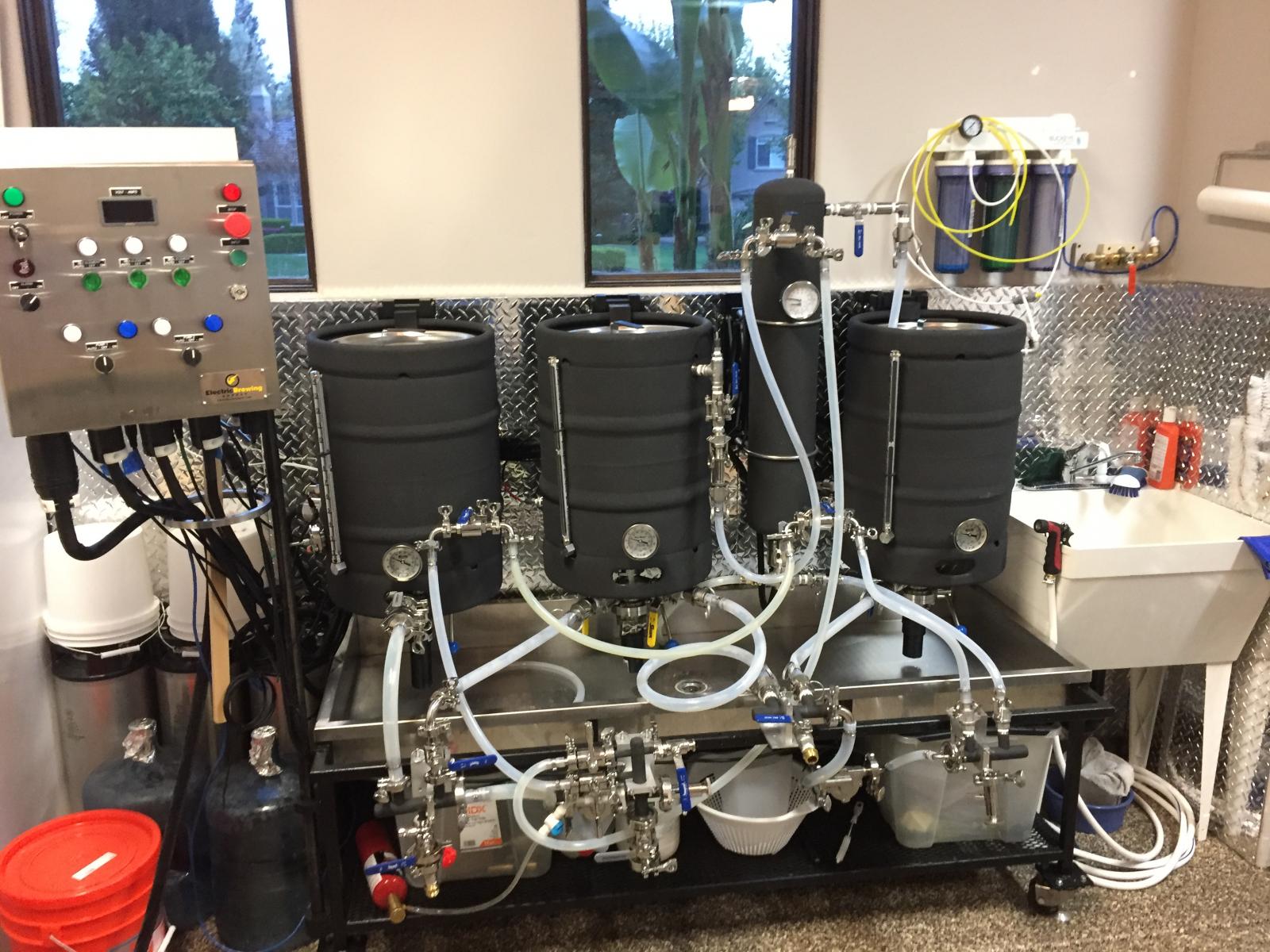

I spent the last 4 months not brewing because I was building up a new more automated brewery. Here are some pics of the build. Thanks!

http://imgur.com/gallery/Tw8SC

After a year in the works, my buddy & I finally finished

Is that a hop filter by the plate chiller ?

Yep - "trub filter" i believe is the term (Bobby sells them at brewers hardware)

I spent the last 4 months not brewing because I was building up a new more automated brewery. Here are some pics of the build. Thanks!

http://imgur.com/gallery/Tw8SC

I'm looking for pictures of breweries (brewstands) that are located behind a bar. Wife says I can build a brewery, but we also need a bar area. Looking at it closely, it would be best if I combined the two. Anyone have pictures of breweries that reside behind a bar ? I haven't gone through all 406 pages of this thread...

I'm looking for pictures of breweries (brewstands) that are located behind a bar. Wife says I can build a brewery, but we also need a bar area. Looking at it closely, it would be best if I combined the two. Anyone have pictures of breweries that reside behind a bar ? I haven't gone through all 406 pages of this thread...

Enter your email address to join: