kal

Well-Known Member

Thanks for the kind words and I'll definitely take you up on that pint if I'm ever in Sweden!

Kal

Kal

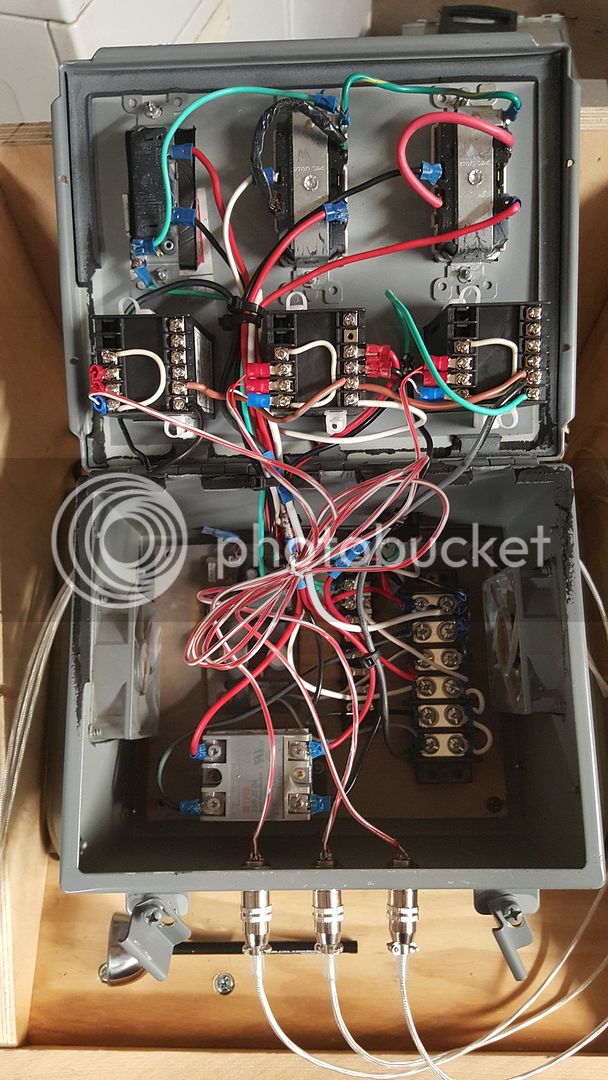

Finally wrapped up my panel today after about a month since starting the project, must still get labels printed and waiting on the kettles to get back from the engineering shop for adding fittings etc but the panel is all done.

It's a full 230v 30A unit, with 12v DC pumps based of Kal's design.

Bomber receptacles. Looks great!

those colored XLR inputs are great lookin...

I just got a couple deliveries today so hopefully get to start on my panel this weekend...

While not as technically advanced as most of your guys' set ups, this was my toolbox-contained RIMS project. First time taking anything like this on, and I'm pretty pleased with how it turned out. The pump is enclosed in the toolbox, so I added an input and an output fan on the back to keep it from overheating. Still need to dial in my PID a bit, but it's been pretty great on the brews I've used it for!

I dont know how to hit the like button, (or I would have) but that is one seriously cool set up there Andrew, very well done)

Decided to go a different route this time

Please tell me you are gonna bring it through an airport when you are done.

Its not the ideal material for a enclosure of this type... there are threads on this if you do a search, Wood works and can be used fairly safely but just like a wooden auto body its just not as ideal as metal or the plastic made for such uses. Still there are wood workers and such who have made some nice panels and it the correct type of standoffs and such are used its likely just about as safe as other materials.I saw one wood enclosure, why not more?

Thanks all. I'll start a build thread one of these days.

Its not the ideal material for a enclosure of this type... there are threads on this if you do a search, Wood works and can be used fairly safely but just like a wooden auto body its just not as ideal as metal or the plastic made for such uses. Still there are wood workers and such who have made some nice panels and it the correct type of standoffs and such are used its likely just about as safe as other materials.

Ask yourself, have you ever seen a wooded fuse or breaker box? they did make radios and tv cabinets out of wood for a long time but most of the electronics where mounted on or in a metal plate or box inside.. and even those are not common anymore.

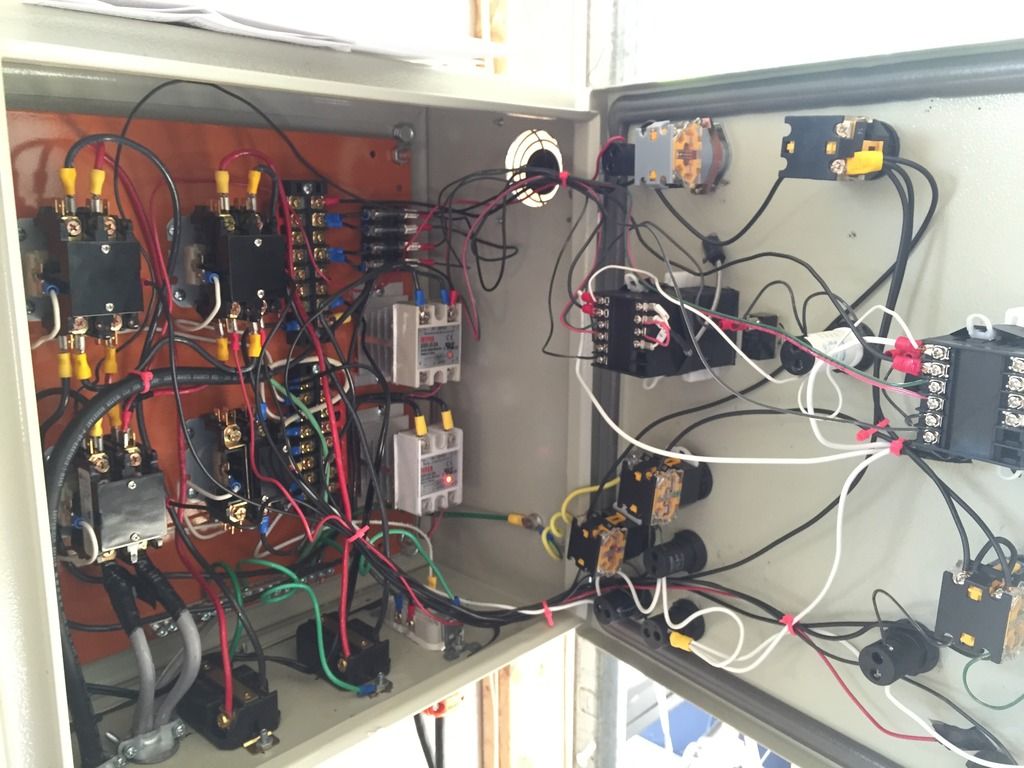

Decided to go a different route this time 'round...

Not quite done with it. But everything is mounted to that faceplate, inside a Pelican case. Going to (hopefully) be a breeze wiring everything and not having to do door runs etc. Plus self contained. Pop that lid shut and it's watertight and indestructible.

What size case is that? I have a pelican case laying around and was tossing around the idea of using it for my panel.

Enter your email address to join: