So I spent the weekend doing some long-overdue projects in the brewery; one of which was to finally customize my brew controllers. Here are a few pics. Feel free to stop by my Facebook page (https://www.facebook.com/PineGroveBrewWorks/) to see more.

Minor upgrade to my panel. It's now able to brew Kessel Run Ale in less than twelve parsecs.

Kal

I just finished my RPi control panel. These pictures show the panel during the build without everything 100% complete. I plugged it in last night and ran it for about an hour in a 30 gallon kettle. Worked great. I have a 200 gallon kettle coming soon. It runs 4 6000watt elements. On the front of the panel it has a key on/off and four switches to turn elements on/off. That way if I'm doing a 5 gallon batch and only need 1 element I can and so on all the way up to a 4 bbl batch. Let me know what you think. BTW it's touch screen and extremely user friendly running the Strangebrew Elsinore by Doug Edey. View attachment 343031View attachment 343032

I just finished my RPi control panel. These pictures show the panel during the build without everything 100% complete. I plugged it in last night and ran it for about an hour in a 30 gallon kettle. Worked great. I have a 200 gallon kettle coming soon. It runs 4 6000watt elements. On the front of the panel it has a key on/off and four switches to turn elements on/off. That way if I'm doing a 5 gallon batch and only need 1 element I can and so on all the way up to a 4 bbl batch. Let me know what you think. BTW it's touch screen and extremely user friendly running the Strangebrew Elsinore by Doug Edey. View attachment 343031View attachment 343032

I'll run another one tonight or at least this weekend and I'll check the ssr temps. I'm going to set up a temp probe for the box. Elsinore comes with an internal heat shut off setting so that you can prevent a blow up.

Even if the temp's not near the "maximum" they recommend, the cooler you run things the longer the parts will last. This is especially true for electrolytic caps as they dry out faster in higher heat. They may still last years, but you can easily cut the life expectancy by 50% with more heatElsinore comes with an internal heat shut off setting so that you can prevent a blow up.

Everything done except the trim around the wood its mounted too. Also was thinking of getting a tv swivel mount so i can move it closer to me a bit while im brewing.

Everything done except the trim around the wood its mounted too. Also was thinking of getting a tv swivel mount so i can move it closer to me a bit while im brewing.

Well if Kal says put the heat sink on the outside then that's exactly what I'm going to do. Brun the way my layout is I think it's to late to put it on the side. I'm going to build a couple more of these for some friends that want them so my next design will be better and cleaner.

Btw it can control up to 4 6000 watt elements. I ordered all the material to build my 4bbl kettle with stand. View attachment 345766

That is definitely the preferred approach for the reasons you state. Best it have the GFI in an electrical panel upstream and separate from the control panel touched by operators.So, if you have a failure between your panel and the wall, the control panel will assume everything is ok, relying on the non-GFCI breakers in your house's panel to trip? Am I reading that correct? That seems a bit dangerous as regular breakers are NOT designed to protect human life, but save wires from burning.

I'd rather have my GFCI protection AT THE SOURCE of power. I have actually had a GFCI trip while brewing in a slight spill situation and I'm glad the power tripped at the wall.

So, if you have a failure between your panel and the wall, the control panel will assume everything is ok, relying on the non-GFCI breakers in your house's panel to trip? Am I reading that correct? That seems a bit dangerous as regular breakers are NOT designed to protect human life, but save wires from burning.

I'd rather have my GFCI protection AT THE SOURCE of power. I have actually had a GFCI trip while brewing in a slight spill situation and I'm glad the power tripped at the wall.

What sort of temps are you seeing inside when running under load for a while?Here's my hosehead clone

What sort of temps are you seeing inside when running under load for a while?

Kal

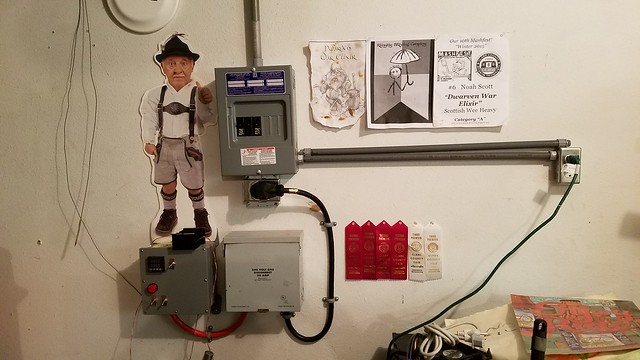

20160326_213302 by Noah Scott, on Flickr

20160326_213302 by Noah Scott, on Flickr 20160326_144251 by Noah Scott, on Flickr

20160326_144251 by Noah Scott, on Flickr IMG_20160326_000242 by Noah Scott, on Flickr

IMG_20160326_000242 by Noah Scott, on FlickrEnter your email address to join: