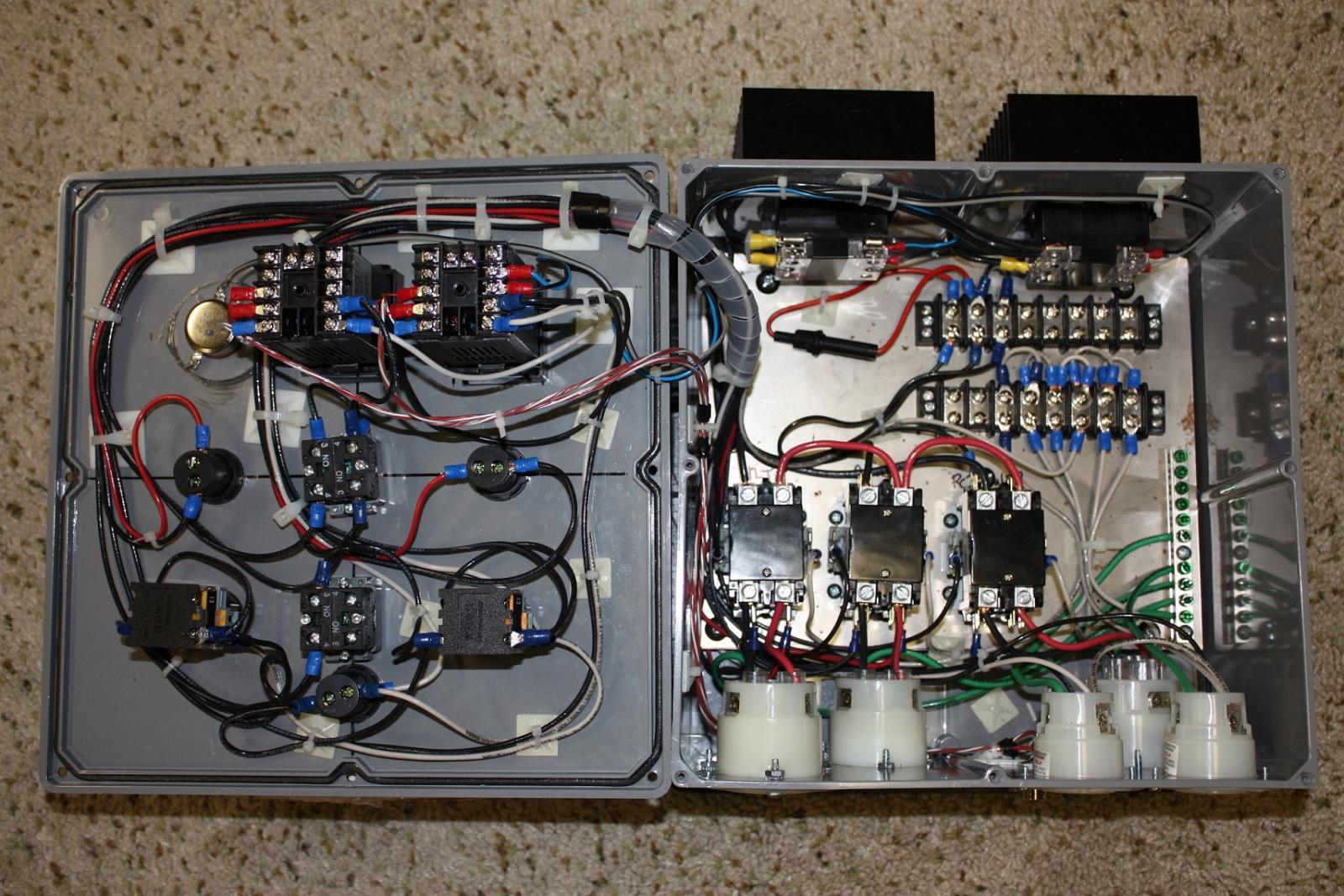

Looks good B^2. That box is packed! 2?:

1. Are those contactors dual throw? If so, are they DIN rail mounted? If so, where did you get them? They look DPST, just checking.

2. Two CFC's. One using flush water and the other ice water for single pass, dual stage chilling?

1. Are those contactors dual throw? If so, are they DIN rail mounted? If so, where did you get them? They look DPST, just checking.

2. Two CFC's. One using flush water and the other ice water for single pass, dual stage chilling?