Hoppopotomus

Cedar Hollow Brewing

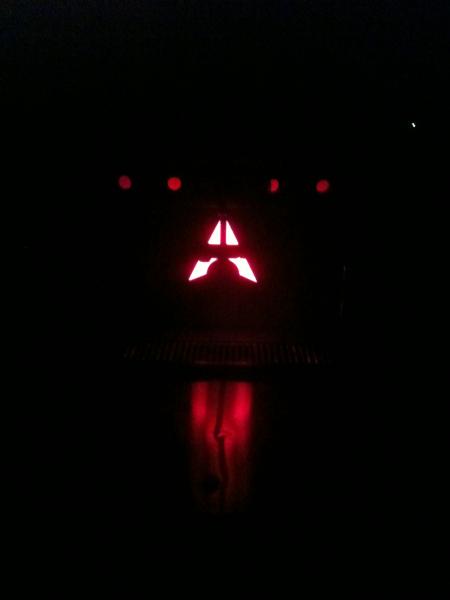

Wow...... I can't believe that I can finally put myself in the good graces of those that have posted their beer dispensing masterpieces!

Here are a few pics of my work. Hope you like. I have a very extensive thread for this build if you care to folllow it. Cheers!

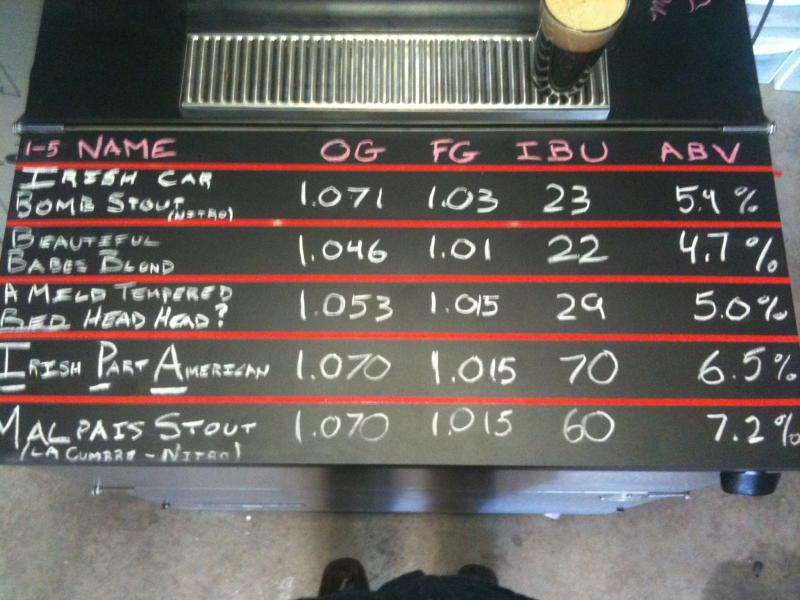

Sorry...the first pic is a mistake. It wasn't supposed to be part of this thread, but oh well.....

Here are a few pics of my work. Hope you like. I have a very extensive thread for this build if you care to folllow it. Cheers!

Sorry...the first pic is a mistake. It wasn't supposed to be part of this thread, but oh well.....