I started with a sketch and ended up changing the layout once all the parts came in:

Laying out the panel front - should have gotten a drill press for this, maybe everything would have lined up....

Handles mounted.

Used

JB Weld for the top, grinding off the screw ends - note the safety glasses - thanks SWMBO!

Grinding Video!

https://youtu.be/-qGRfK_-n6k

Heat sink and

handles installed.

Work table full of stuff.

More wiring.

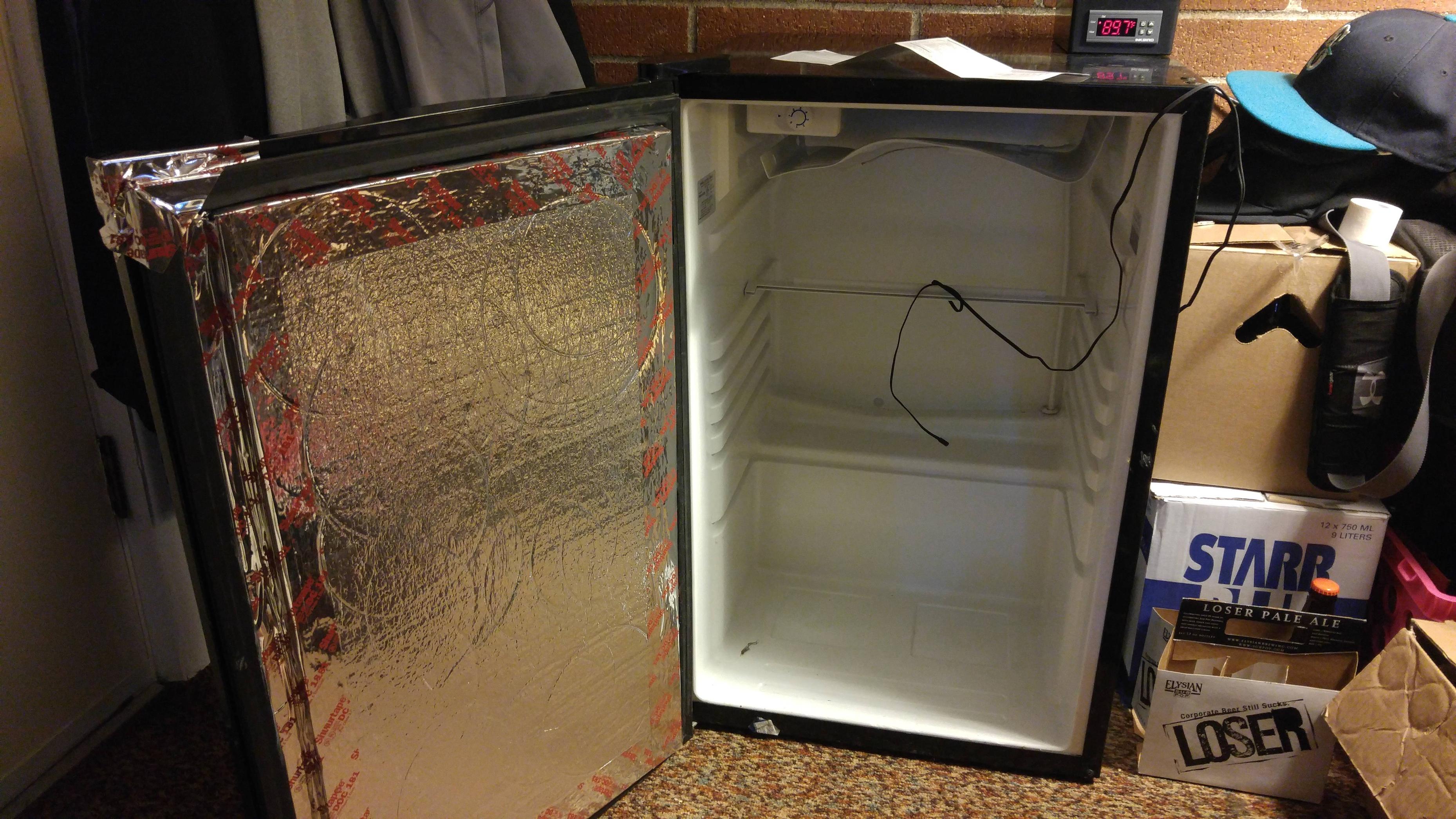

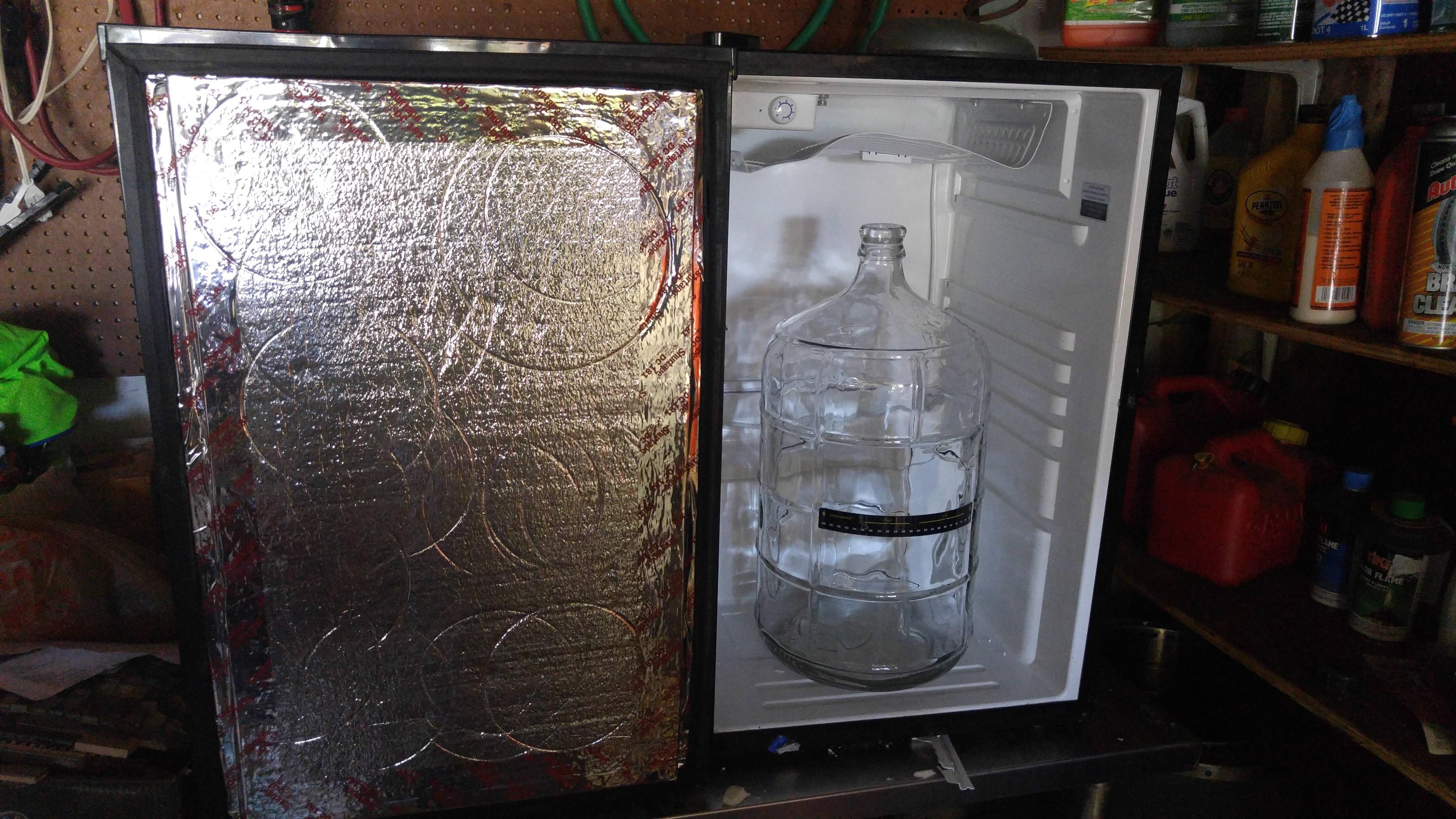

Even more wiring - using a light as a test keezer.

Starting to mount the controllers and weather station.

After painting.

Rewiring power adapters.

Pulled the blades and inserted wires.

Power converter board.

Testing

SS Brewtech pump controller.

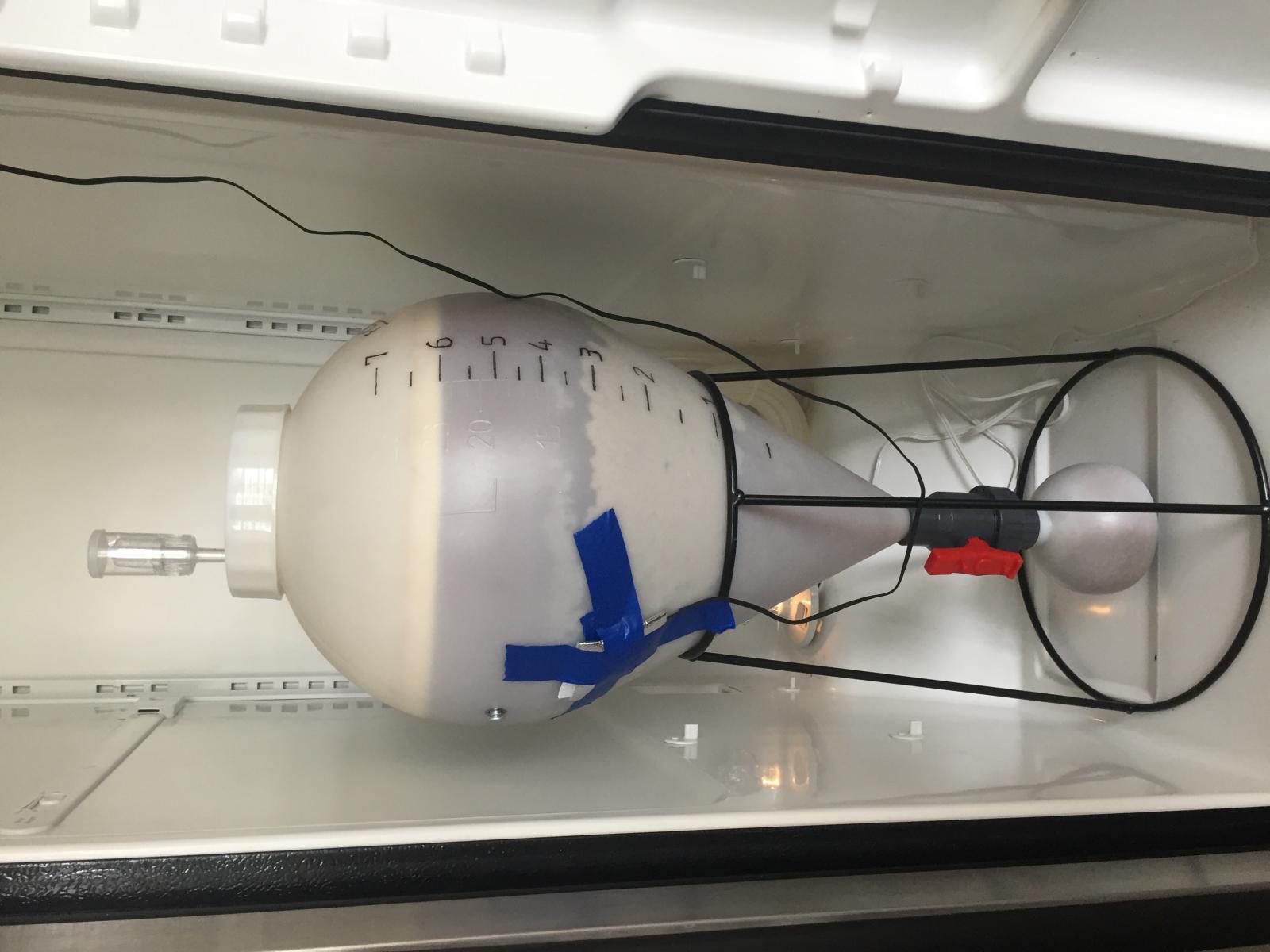

SS Brewtech Controllers the way they were designed to work on the fermenters.

Starting wiring up the controller for reals.

Everything wired and operational.

First power ups!

Testing continues.

More testing.

Even more testing.

All working!

Video of panel working with all working lights engaged:

https://youtu.be/NwTyNAHTCiA

A matched pair!!

Sweet!

Starting the wiring process.

Mounting controller to wall - cut the back out and mounted it over a double GFCI outlet. Wired in the Keezer, Freezer and Cooler directly to the solid state relays. The rest of the wires are leads for temperature sensors and power leads from the appliances.

Ran all the wiring behind the wall and under the stainless shelf.

Up and completely operational controlling all devices prior to first brew.

Video of panel working on wall of brewery:

https://youtu.be/R7ATFciW_VI

I'm ready for my close up!

Everything working as planned!