BayerischBier

Well-Known Member

Any trouble with the the burner's heat and being so close to the studs/wood?

I see some metal in the back.

Any thoughts?

I see some metal in the back.

Any thoughts?

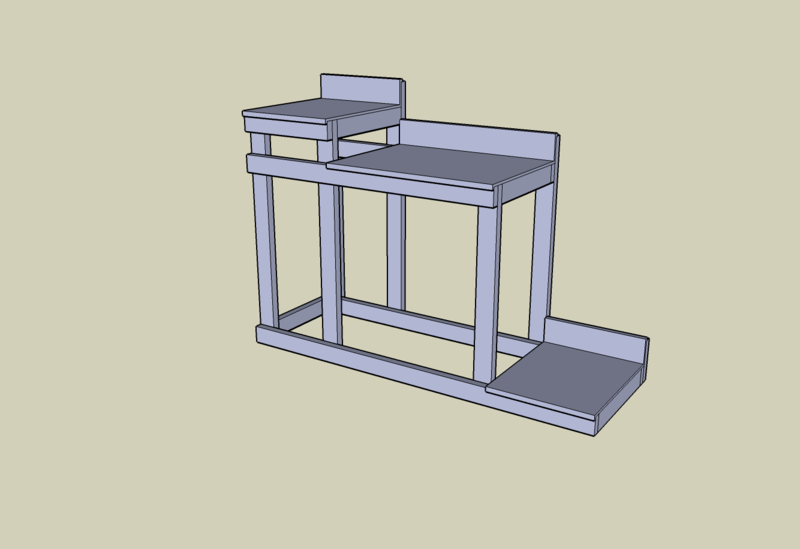

My pallet wood brewstand: