- Joined

- May 28, 2018

- Messages

- 3,034

- Reaction score

- 2,433

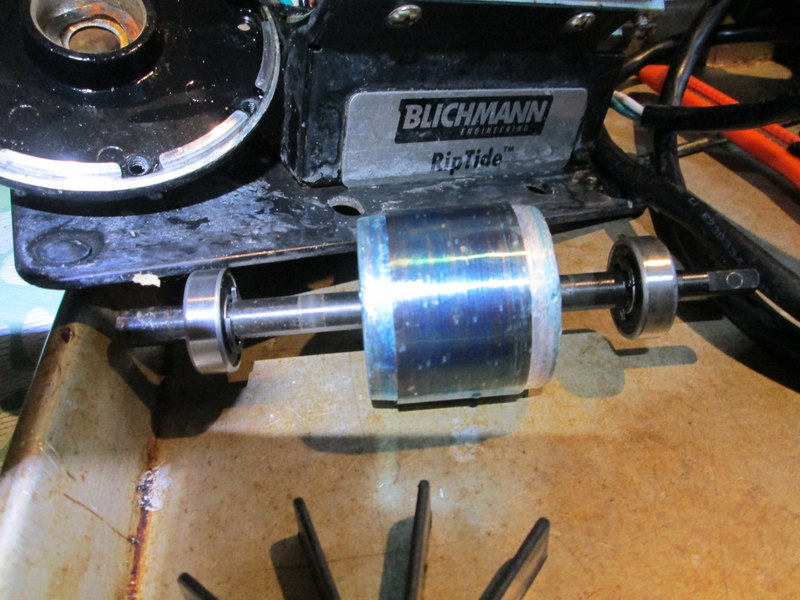

Started vorlauf today and my pump was making a lot more noise than usual. After finishing vorlauf, I took off pump head and all looked fine. Ran the motor only and determined noise was coming from the motor, not the pump head.

I did not want to get too far into it today as am in middle of a batch, but took pump apart enough to open a gap in back plate and sprayed a little penetrating grease in there. Put back together and motor is still making noise, but not quite as much, so some got in there.

Will do a full disassembley when not in use, but wonder if anyone else has experienced this, and what they did about it.

Pump still works fine, but one of the benefits of Riptide over old March it replaced was the lack of noise. Besides, my guess is it will only get worse if not addressed.

I did not want to get too far into it today as am in middle of a batch, but took pump apart enough to open a gap in back plate and sprayed a little penetrating grease in there. Put back together and motor is still making noise, but not quite as much, so some got in there.

Will do a full disassembley when not in use, but wonder if anyone else has experienced this, and what they did about it.

Pump still works fine, but one of the benefits of Riptide over old March it replaced was the lack of noise. Besides, my guess is it will only get worse if not addressed.