Hey all. I'm working on a custom-made refrigeration chamber, the reasons for which I have discussed elsewhere and don't want to get into now.

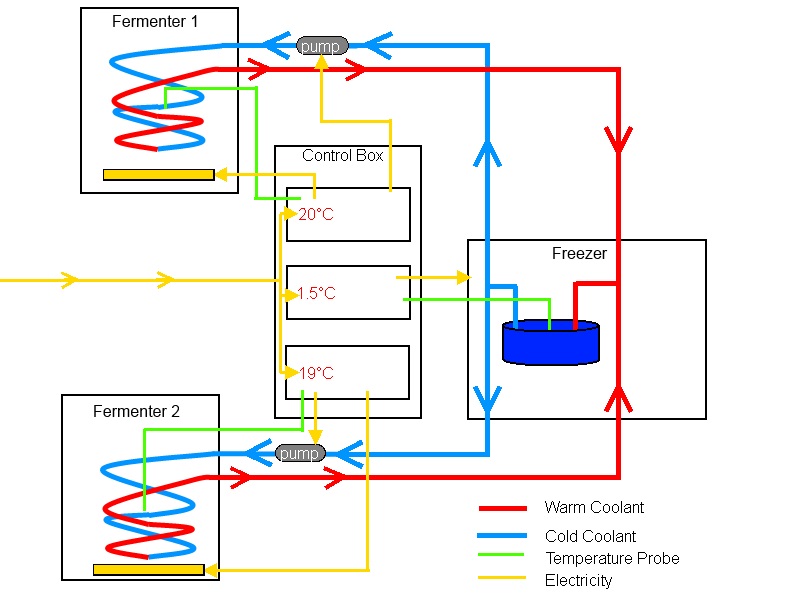

Here is my design:

The frame of this monstrosity is a W40cm x L45cm x H130cm metal rack from the hardware store, with walls of styrofoam insulation.

Basically, I'll put a bucket of anti-freeze into a freezer, and pump it through vinyl tubes going around the outside of my fermenters to cool. Temperature monitoring and control will be provided by three STC-1000s, powering the freezer, pumps, and a couple of electric blankets. I will have a lot of room leftover in my freezer, so I am going to add another controller to the freezer to maintain it at 1.5 C, just above freezing, so I can store some yeast and hops in there. If I have room, I may even try to jam in a keg once I start kegging.

My questions are about the pumps.

1) How do I calculate the size/strength of pump I need?

2) I assume that pumping antifreeze instead of water will affect a pump's flow rate- is it likely to completely stop it?

3) Will most pumps have problems with pumping at near-freezing temperatures?

4) Will I be okay using an underwater pump in the antifreeze?

I'm looking at a couple of aquarium / fountain pumps and expensive inline pumps, but I'm not sure which to go with. I don't want to waste another chunk of change, after the $100 fridge that didn't fit in my beer closet.

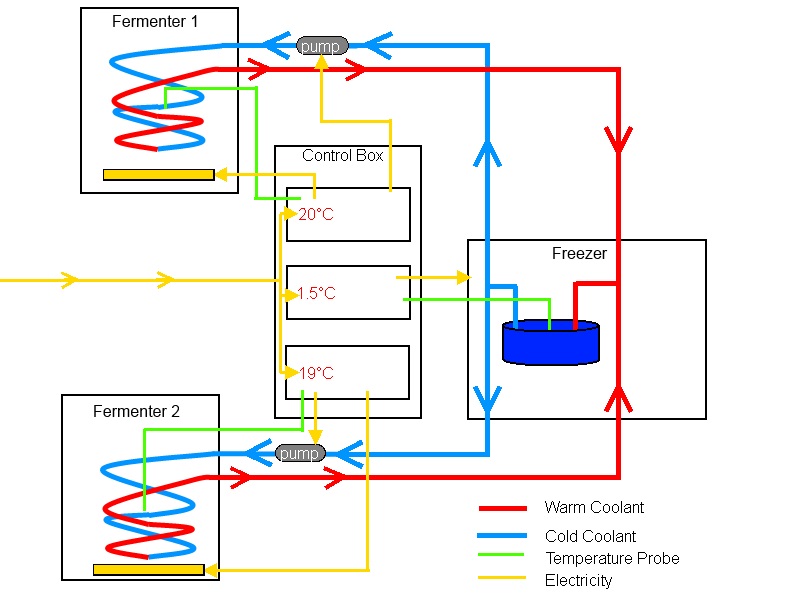

Here is my design:

The frame of this monstrosity is a W40cm x L45cm x H130cm metal rack from the hardware store, with walls of styrofoam insulation.

Basically, I'll put a bucket of anti-freeze into a freezer, and pump it through vinyl tubes going around the outside of my fermenters to cool. Temperature monitoring and control will be provided by three STC-1000s, powering the freezer, pumps, and a couple of electric blankets. I will have a lot of room leftover in my freezer, so I am going to add another controller to the freezer to maintain it at 1.5 C, just above freezing, so I can store some yeast and hops in there. If I have room, I may even try to jam in a keg once I start kegging.

My questions are about the pumps.

1) How do I calculate the size/strength of pump I need?

2) I assume that pumping antifreeze instead of water will affect a pump's flow rate- is it likely to completely stop it?

3) Will most pumps have problems with pumping at near-freezing temperatures?

4) Will I be okay using an underwater pump in the antifreeze?

I'm looking at a couple of aquarium / fountain pumps and expensive inline pumps, but I'm not sure which to go with. I don't want to waste another chunk of change, after the $100 fridge that didn't fit in my beer closet.