- Joined

- Aug 8, 2017

- Messages

- 1,509

- Reaction score

- 1,780

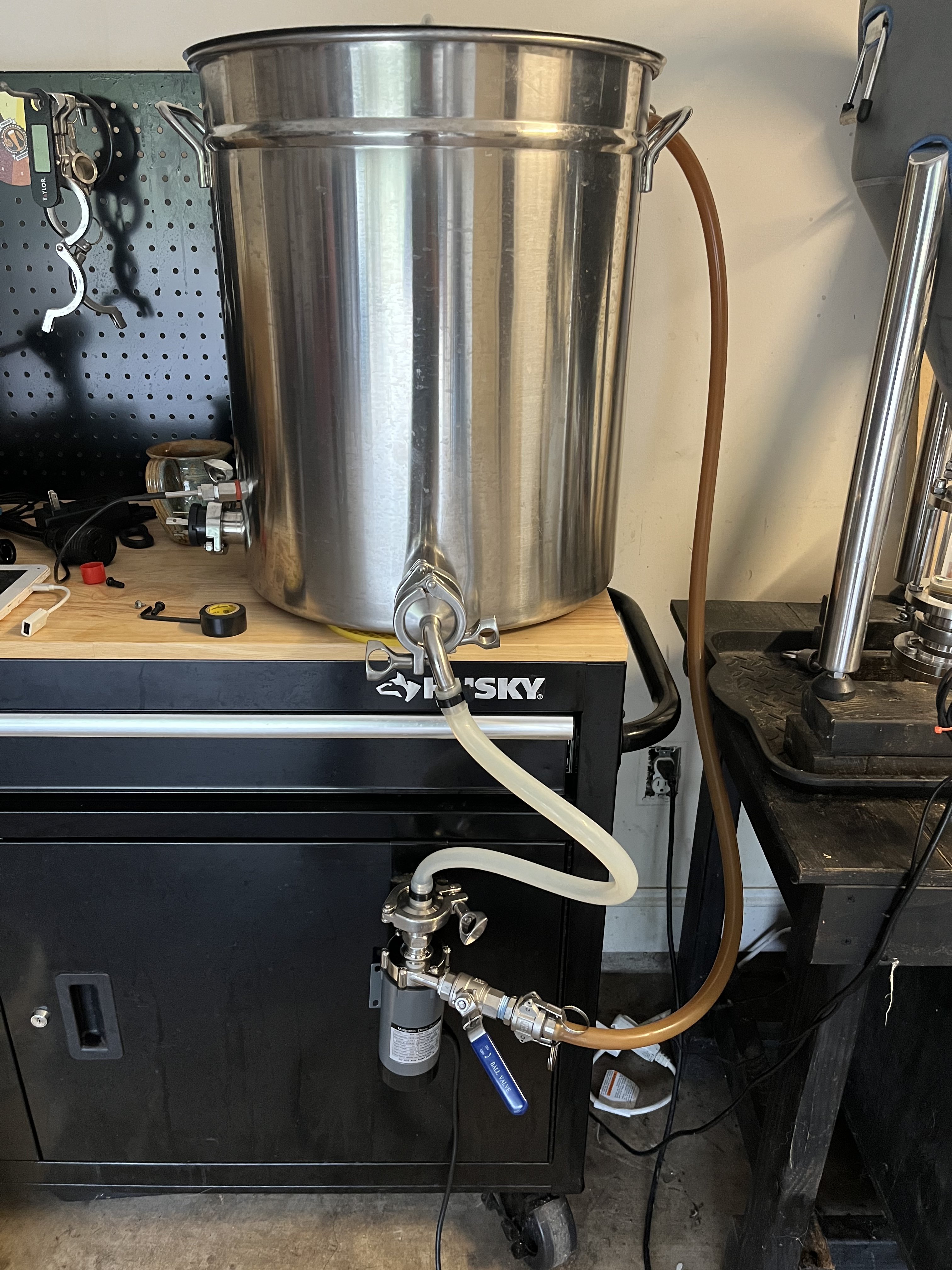

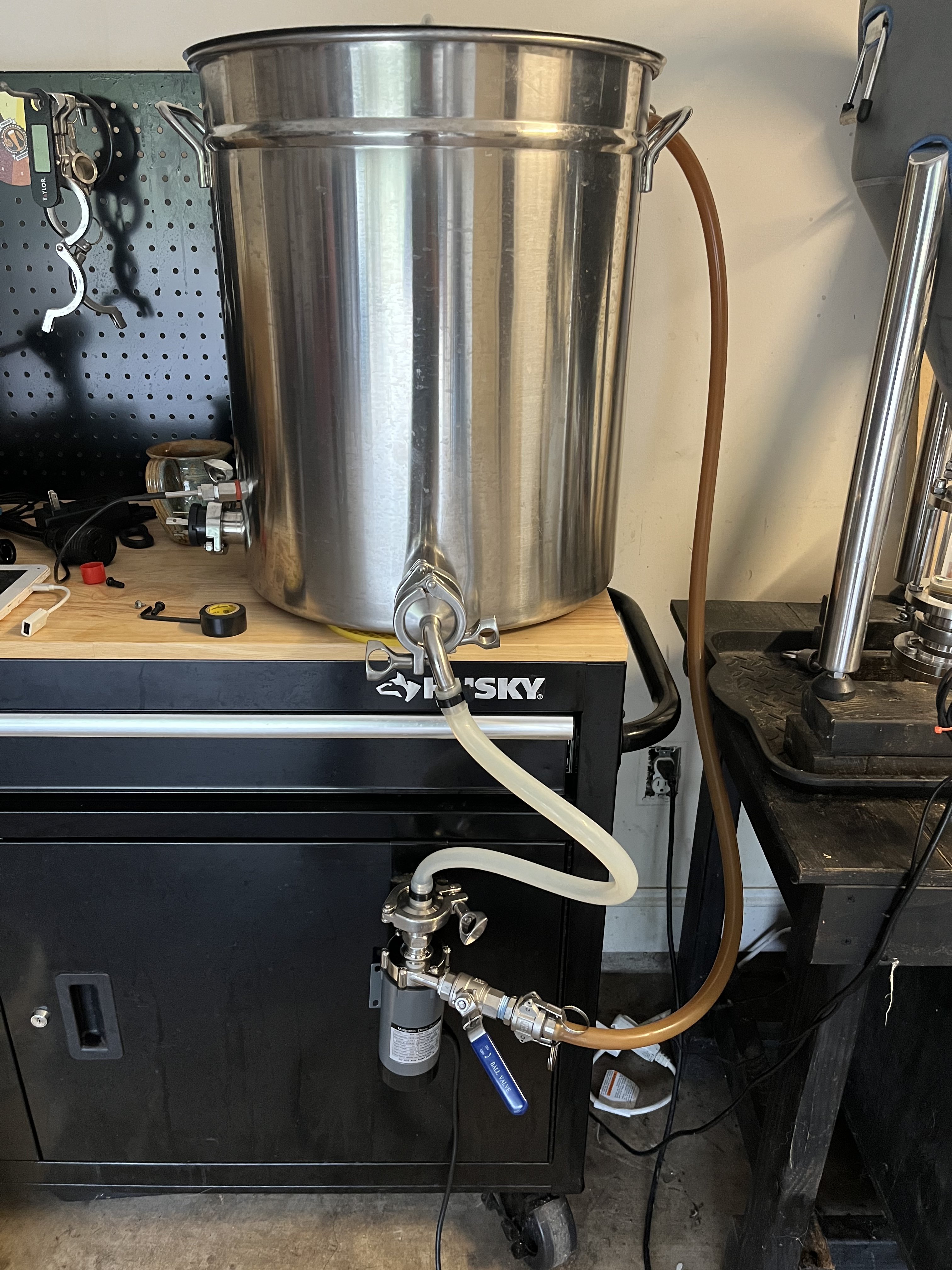

Watched a video on mounting the pump but I am not sure if I can mount it vertical?

Does this look ok? It primes perfectly and works great although the pump motor gets extremely hot.

Does this look ok? It primes perfectly and works great although the pump motor gets extremely hot.