Ok so I jumped the gun as normal and bought 4-30 gallon HDPE #2 drums. They were originally used to hold syrups/concentrates, mostly apple.  They are marked w/ lines for every 5 gallons up the side, have 2 screw type caps/ openings in the top and are a blue in color.

They are marked w/ lines for every 5 gallons up the side, have 2 screw type caps/ openings in the top and are a blue in color.

I was thinking that I could use these as fermenters. I am very close to be moving outside onto a make-shift brew stand but that will be set before these; and should be ready soon.

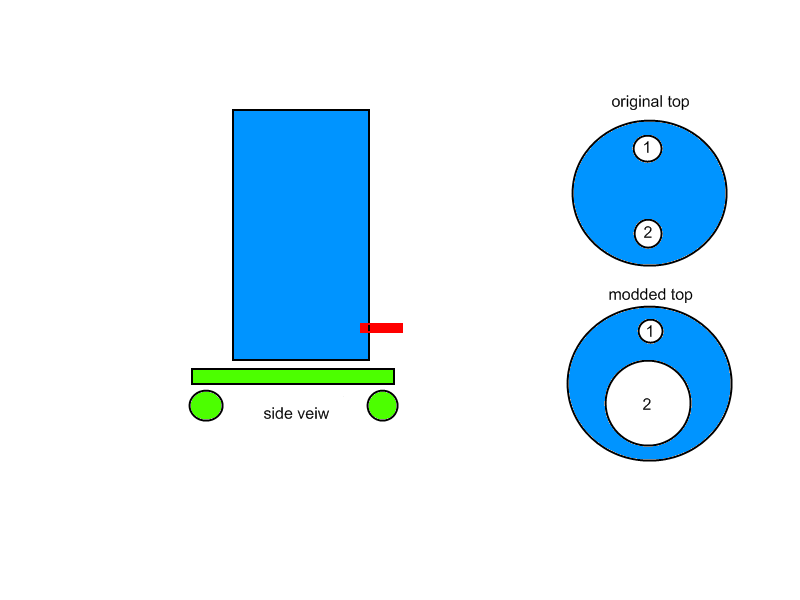

I also have started looking into a few hydrolic "lift carts" to aid with transfers.

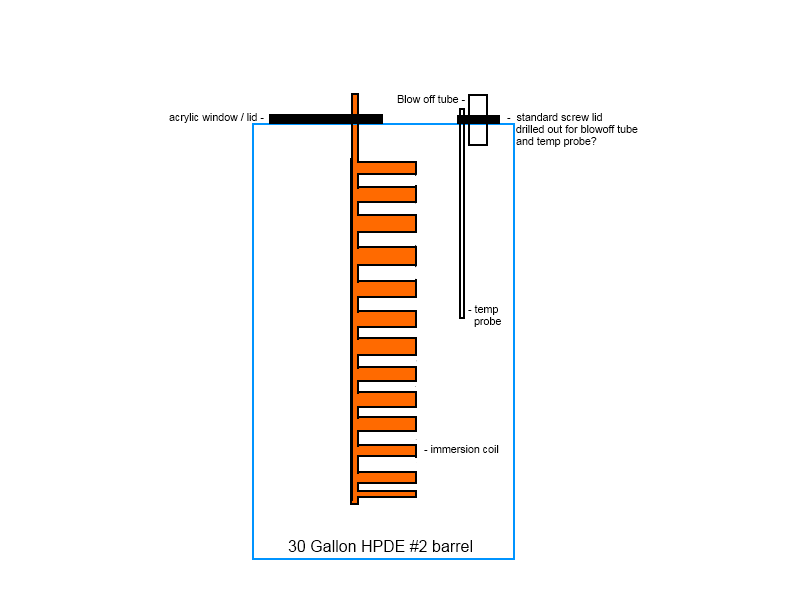

I will further plan to cut an off-center hole, in the top that will be a window/ access lid inside for inspections,cleaning and mounting a spigot near the bottom. I will then use the other "cap/lid" to have a blow off tube.

My questions are:

-Other than the obvious things like weight limits, be sure to clean/sanitize them and some oxygen permeability are there any other issues I should be concerned about?

- If others are also using these, what spigot/ball valve would be a good choice to install in the bottoms for transfers (I am thinking SS like the keggles...)?

any other advice?

BTW The score was pretty good even if they are near worthless for brewing, I only paid $50.00 for everything: 4-30 gallons and 2-55 gallons (the 55's are for a different project...)

I was thinking that I could use these as fermenters. I am very close to be moving outside onto a make-shift brew stand but that will be set before these; and should be ready soon.

I also have started looking into a few hydrolic "lift carts" to aid with transfers.

I will further plan to cut an off-center hole, in the top that will be a window/ access lid inside for inspections,cleaning and mounting a spigot near the bottom. I will then use the other "cap/lid" to have a blow off tube.

My questions are:

-Other than the obvious things like weight limits, be sure to clean/sanitize them and some oxygen permeability are there any other issues I should be concerned about?

- If others are also using these, what spigot/ball valve would be a good choice to install in the bottoms for transfers (I am thinking SS like the keggles...)?

any other advice?

BTW The score was pretty good even if they are near worthless for brewing, I only paid $50.00 for everything: 4-30 gallons and 2-55 gallons (the 55's are for a different project...)