Mike Vogan

Active Member

- Joined

- Aug 7, 2019

- Messages

- 37

- Reaction score

- 3

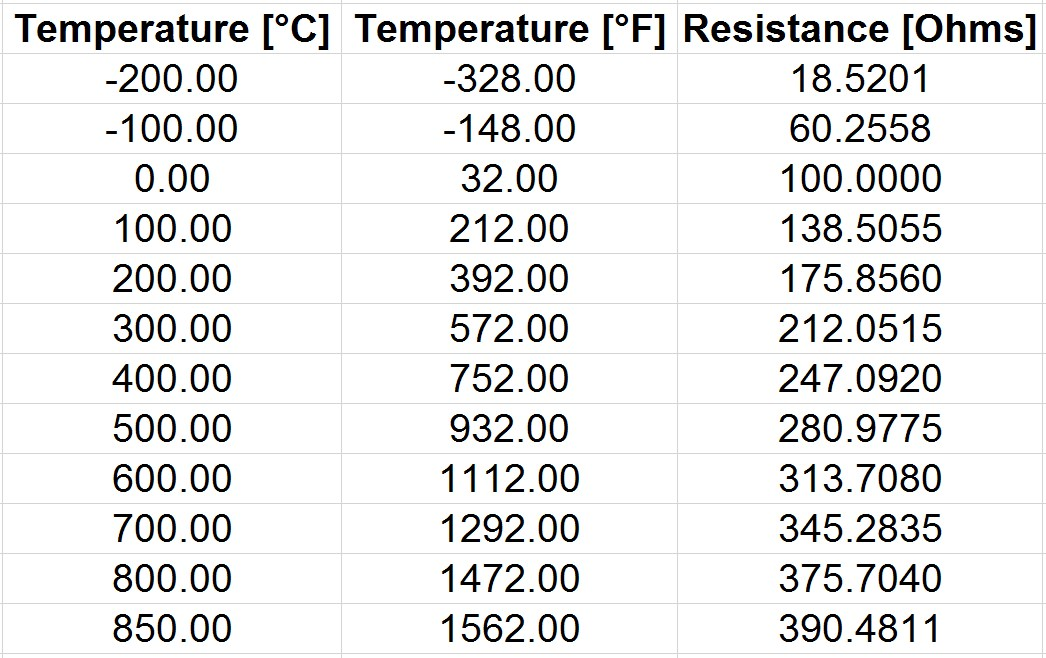

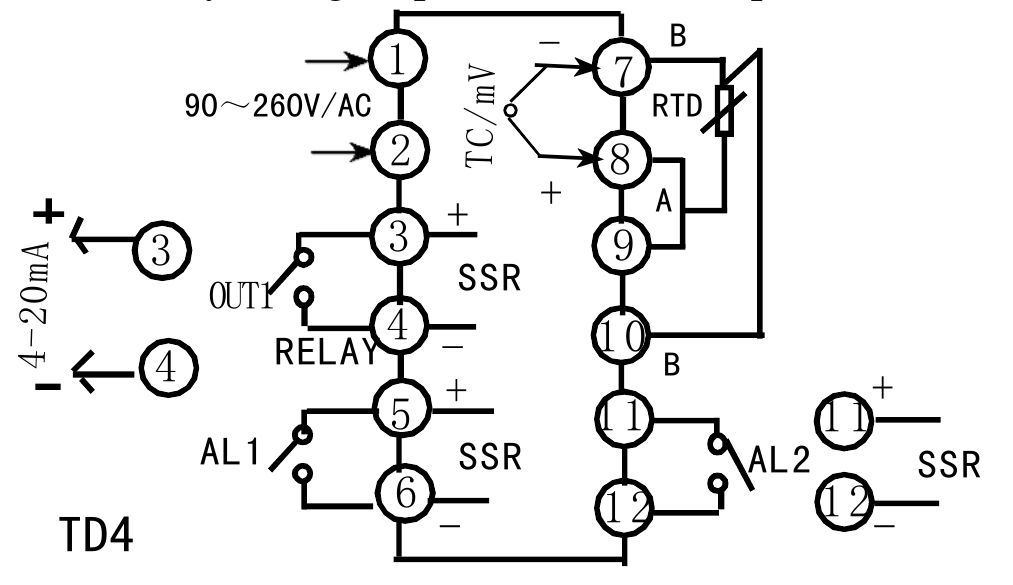

Hey group Thought maybe ya'll could help me on this problem I have the Mypin T4 controller with the RTDPT100 temp probe This is a new probe and since its been in I have been having this problem I am assuming that the probe isnt right But the temp constantly reads whatever temp is on the PV and it wont change in an ice water bath or being heated Am I correct in my assumption that its the probe ? Or could it be something else I have switched wires til Im sick of looking at them Any ideas or just a plain simple solution would be very nice Thanx in advance for any help with this Before I forget this probe has 3 wires Black Red and Blue Where should they go and in what order ?