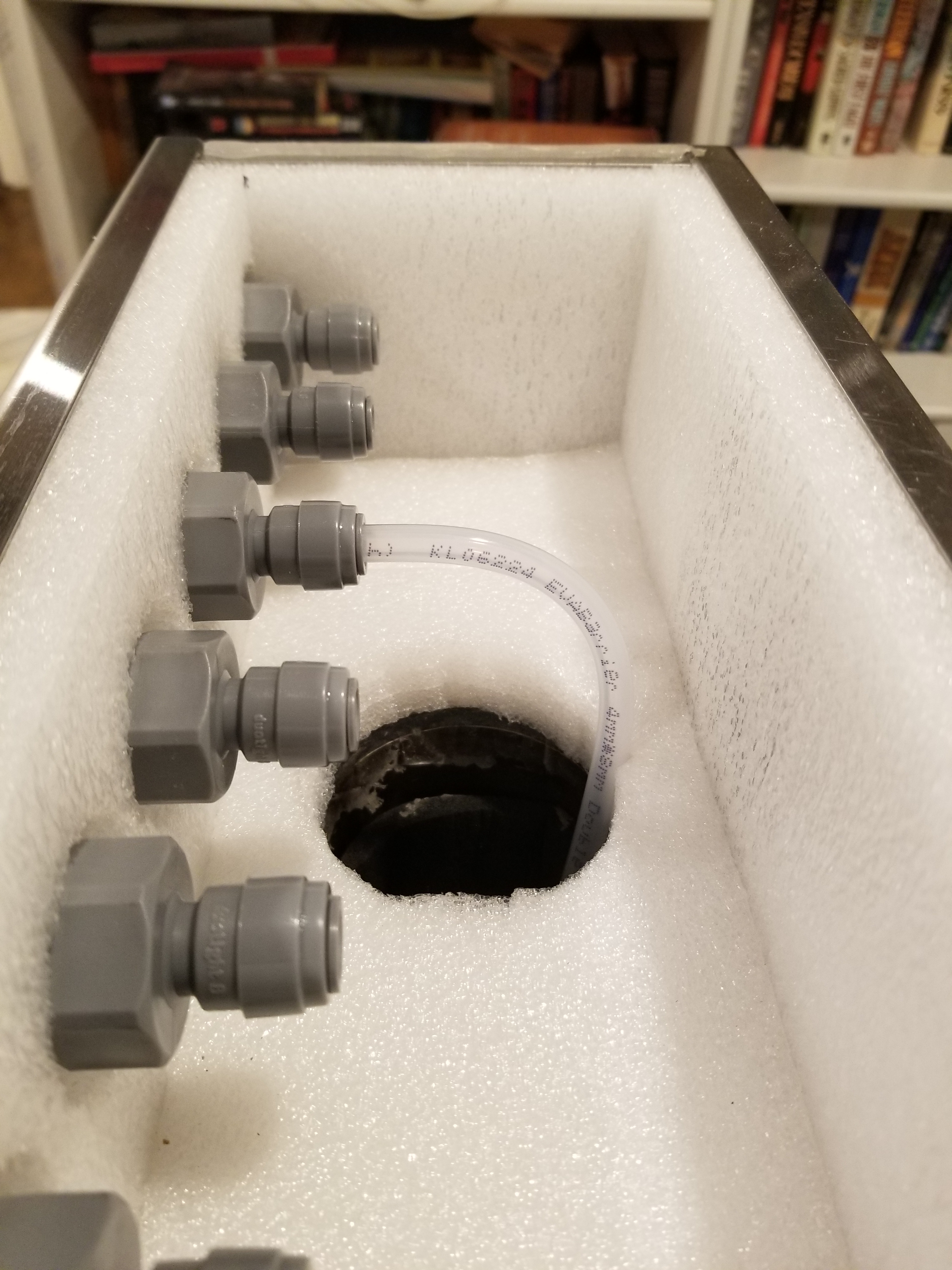

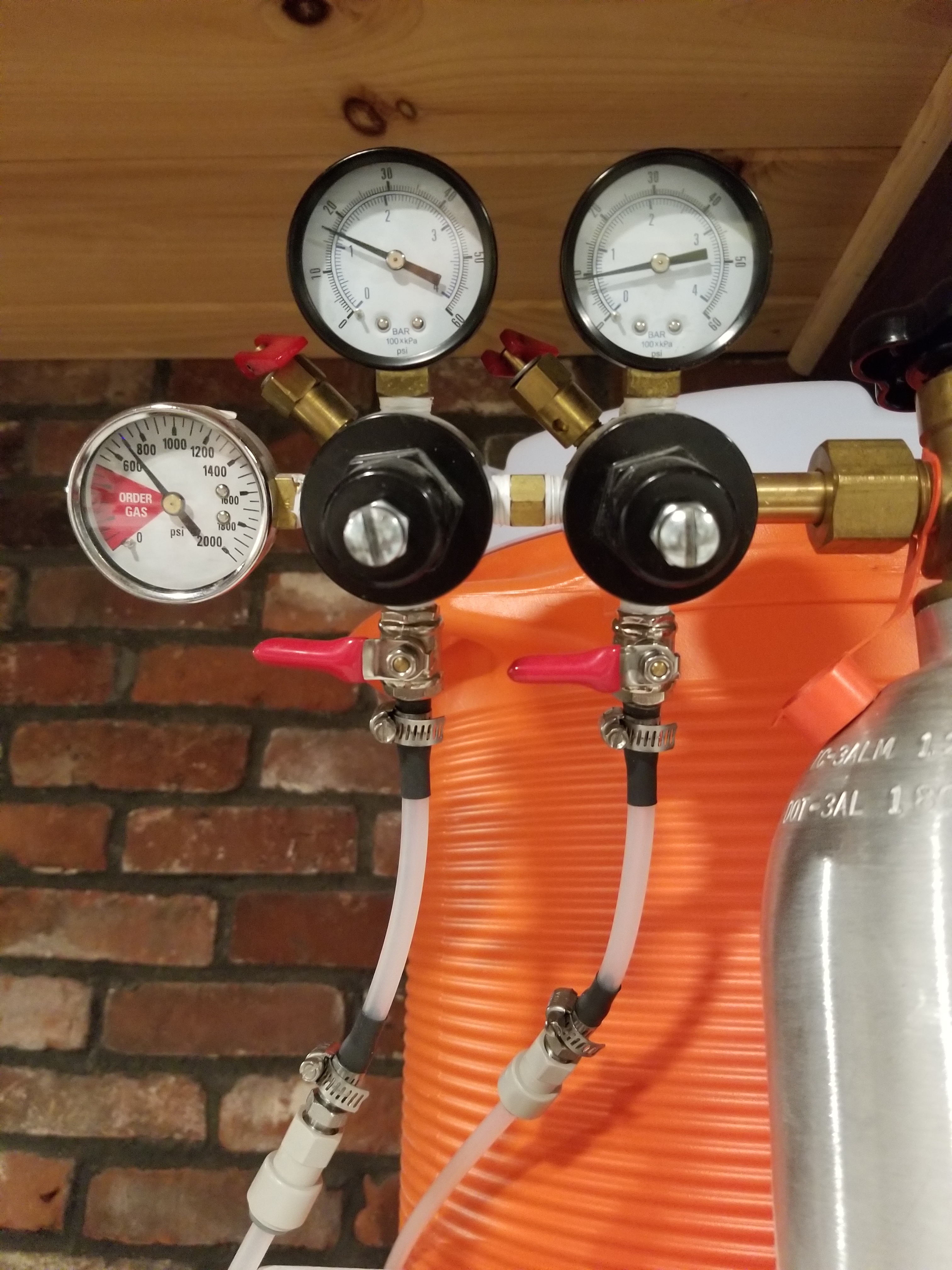

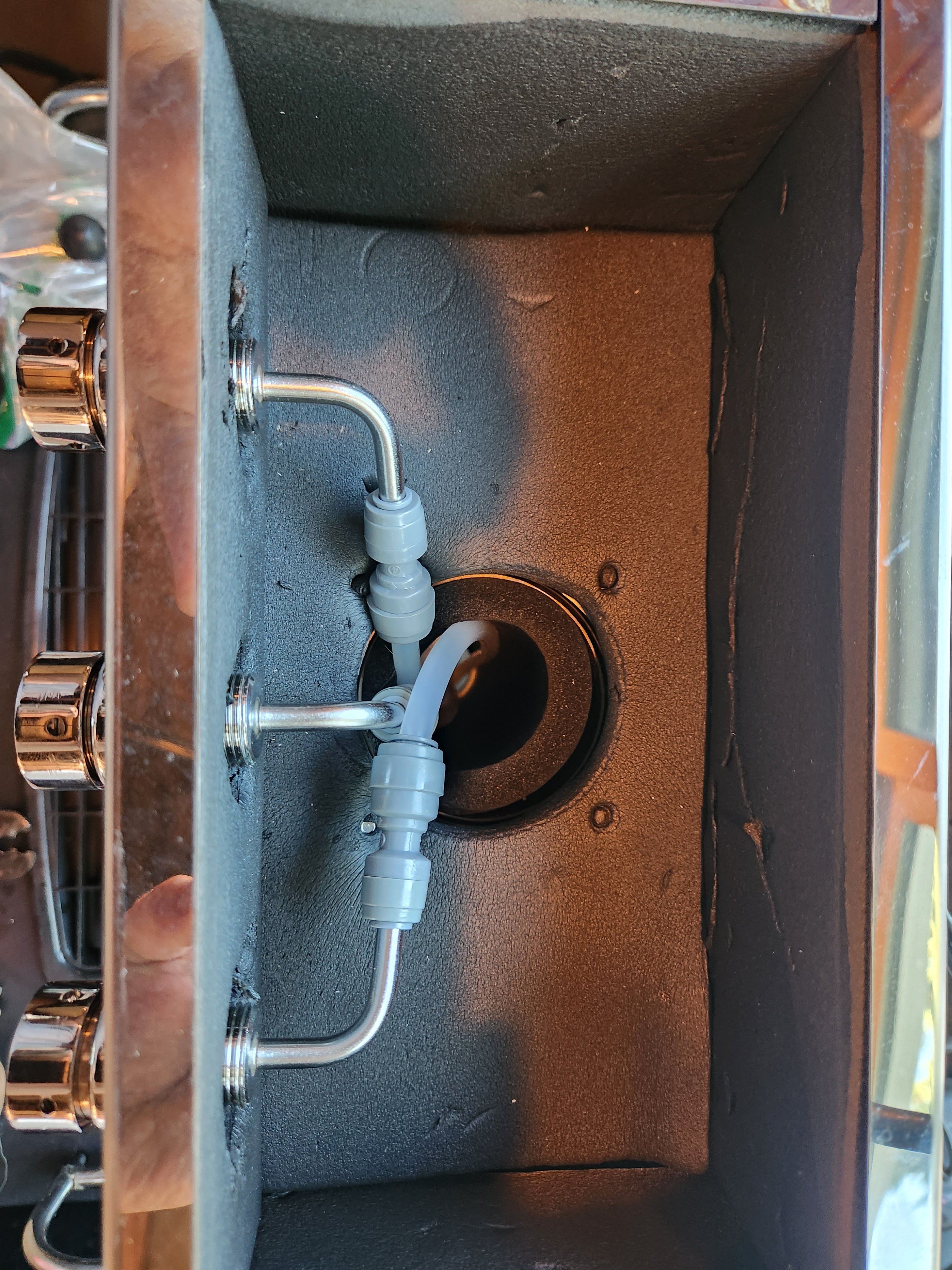

hey guys long time no see. I been out the game for a while and I finally made the leap to kegging. I got a hang up on a second hand keezer i bought and need some advice.

The lines need replacing and what I thought was gonna be an easy task to just change out the vinyl tubing I see there are lots of options now and I have decided since its getting replaced i go with the Eva route.

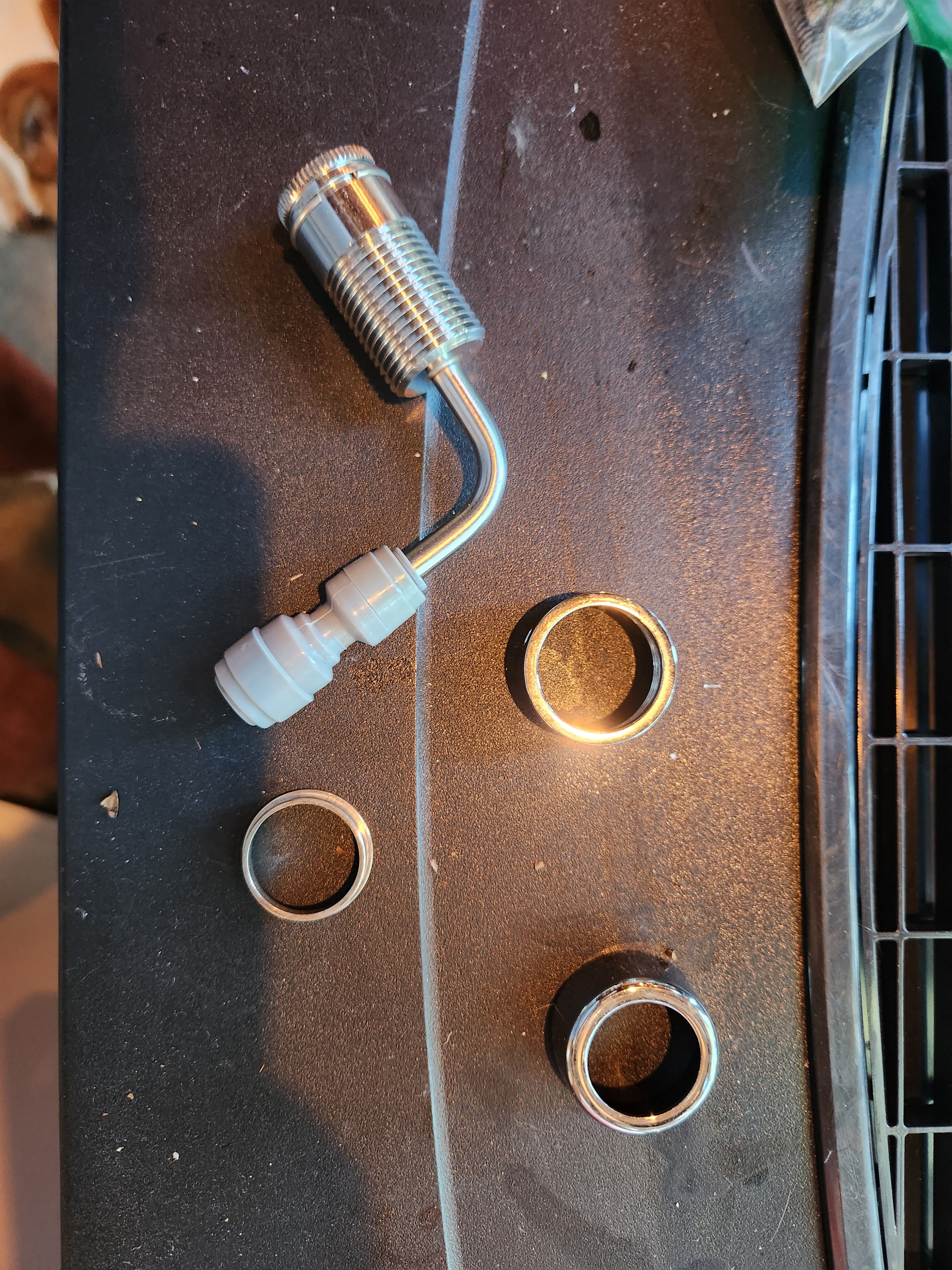

I have been researching this for hours now and my eyeballs are bleeding. I have a PERLICK 630SS type faucet already installed and I see that the barbed end is not duotight friendly from what i have researched. am i SOL or can i cut that thing off with my grinder and attach this fitting to it?

Thanks in advance.

The lines need replacing and what I thought was gonna be an easy task to just change out the vinyl tubing I see there are lots of options now and I have decided since its getting replaced i go with the Eva route.

I have been researching this for hours now and my eyeballs are bleeding. I have a PERLICK 630SS type faucet already installed and I see that the barbed end is not duotight friendly from what i have researched. am i SOL or can i cut that thing off with my grinder and attach this fitting to it?

Thanks in advance.