So I stumbled across this article the other day:

https://www.brewpi.com/what-is-ideal-herms-coil-length-theory-experiments/

The further I got into the article the more the analysis motivated me to do my own. They neglect some of the true physics at play and treat many variables as fixed constants (friction coefficient and pump performance). While they do qualify that the results are system dependent they provide an optimum for the topsflo pump which I don't think as many people use.

The problem is that the "optimum" length of your coil is massively dependent on the performance of your pump and your individual system. So I set out to do a real analytical optimization of a HERMs coil for a set up that is more like the system that I brew on.

This section is about the calculation, feel free to skip:

If you want a good primer on fluid flow in pipes start here:

https://www.engineeringtoolbox.com/total-pressure-loss-ducts-pipes-d_625.html

In order to solve the D'Arcy-Weisbach Equation [hloss = λ (l / dh) (v2 / 2 g) ]

We need to solve for λ a.k.a The friction coefficient can be calculated by the Colebrooke Equation:

1 / λ1/2 = -2.0 log10 [ (2.51 / (Re λ1/2)) + (k / dh) / 3.72 ]

Because the formula is recursive we will have to solve this by iteratively. I used quartic iterations. Which should yield results many orders of magnitude more precise than the Nusselt number approximations use later on later on.

I took the pump curve from March for the 815-SS available here: http://www.marchpump.com/site/files/966/148215/489110/710019/815-SS.pdf

manually copied a few of the data point and and fit the curve.

Here is the pump curve fit:

I assume for this analysis that you have 2x 4ft silcone 1/2" hoses in addition to your HERMS coil running from your pump to the inlet and exit of the HERMS coil. For minor loss calculation I assumed 1 ball valve all the way open, 4 right angle fittings, and 4 cam-lock pairs. Minor loss coefficients (ξ) can be summed and added to the major losses.

hminor_loss = ξ v2/ (2 g) (1)

where

hminor_loss = minor head loss (m, ft)

From here we have the problem of solving for the steady state system operating point. Where we match the available head from the pump with loss in the system. This must be solved iteratively as well as the losses are a function of fluid velocity and the available head is a function of the fluid velocity as well. The iterative solver will stop once the apparent error is within 0.1%.

The script will also solve for both laminar (full and partially developed) and turbulent flows and adjust the Nusselt number, the friction factor, heat transfer coefficients accordingly. (turns out that most of the flow cases with this pump and reasonable coil lengths are sufficiently turbulent (Re>10,000) but for the pump in the article and some smaller pumps that is not the case.

I swept through lengths of HERMS coils from 1 to 70 ft as well as Mash to HLT temperature deltas of 1 to 20 degrees. The results follow.

END OF METHODOLOGY

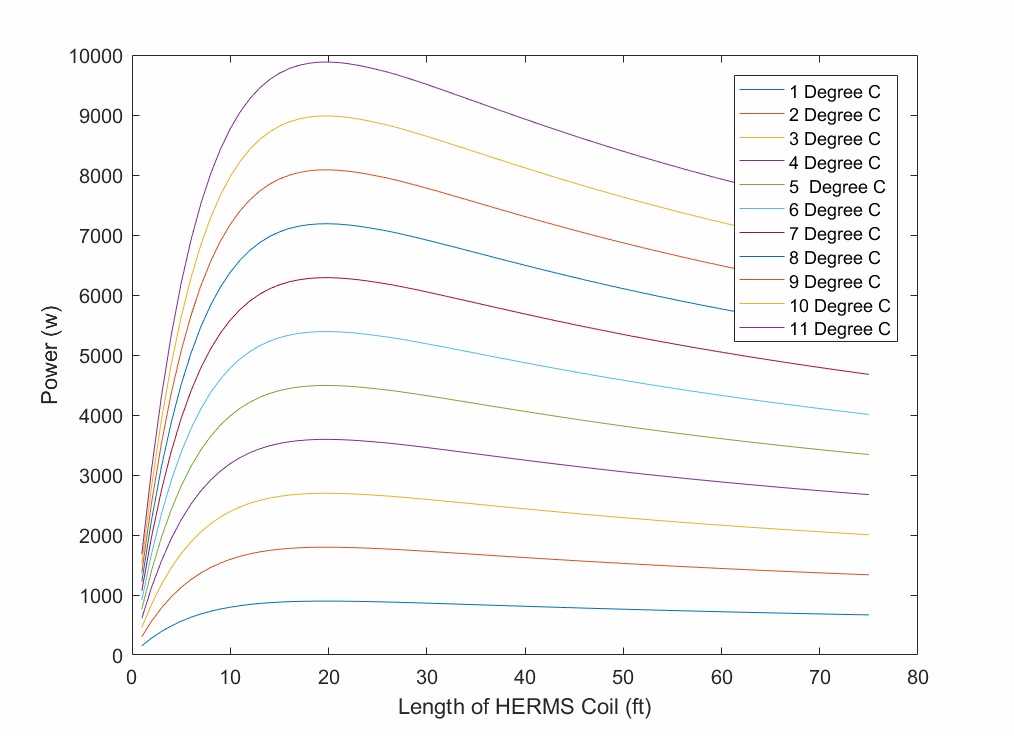

The family of curves below is for the March 815-SS pump (one of the most common brewing pumps in the US) and assumes you have two 4ft lengths of 1/2" dia silicone hose with 90 elbows and cam lock fittings, a ball valve that is all the way open on your pump, 1/2" OD stainless steel tubing for the coil (0.035" wall), and that you can maintain constant temp in your mash tun (i.e. you can provide the same heat you are extracting).

One thing the article kind of neglected is that you don't necessarily want higher HERMs outlet temps. Heat transfer is maximized when the temperature difference between the two materials is large. What that means is that the closer your wort temp in the HERMs coil gets to the HLT temp the less heat transfer into that fluid you get for the same area of heat exchanger. Additionally they neglect the fact that you don't want the wort to get above 168F at all or you will start denaturing all of your amylases. On that note, you really want to do all you can to decrease the heat load on those amylases; therefore, you really want to have as small of a HERMs outlet temp differential as possible with a high flow rate*.

The first run I just spit out the power vs. coil length but neglected the outlet temp and you get the graph below, which just says you want as big of a temperature difference between your mash temp and the HLT tempas you can get with a coil length of about 20ft.

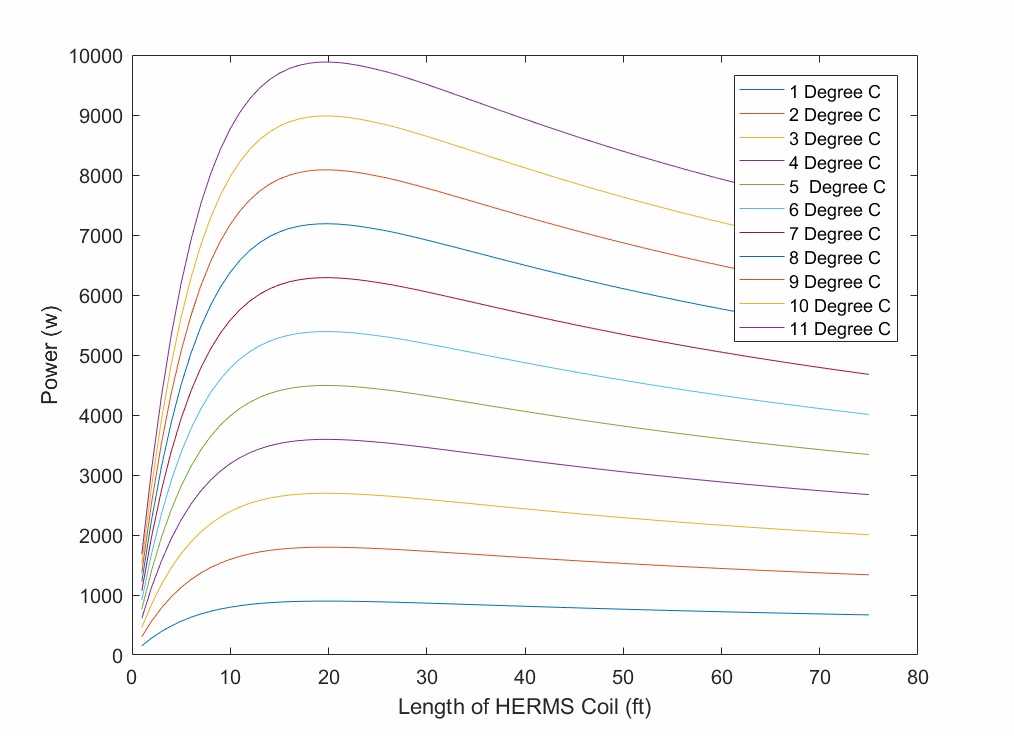

The second run I killed each curve when the outlet temp increased above 165F (74C) which is why you see that strange feather shape on the left. The straight line back to zero is just a bug in how I plotted it (sorry), the curve should terminate at the top. What this says is that your maximum "enzyme safe" temp delta is 9C (16F) and at that delta T you want about 18ft of coil (yields a flow rate of ~3.5gpm**). You can technically get a higher power system with the same pump if you have a very short coil but because that slope is so steep you run the risk of easily mis-estimating the head loss and not getting much power transfer at all or cooking your wort. To me, the risk is not worth the marginal power increase from the 9C delta set up. Also, that would need a very high flow rate and I think that would probably just result in a ton of grain bed settling, restricting your flow and then cooking your wort.

About those *'s, I'm not sure that 3.5 gpm is a reasonable flow rate for most mashes. I will have to see how bad that compacts my grain bed and report back. If it proves to be too high it will push the "optimum" coil length longer.

SO,

Lessons learned:

-You don't need the expensive 50+ foot coils everyone is trying to sell you

-Next time someone asks you what the optimum length is just tell them 18 ft

-Next time I see an article about brewing that relates to “engineering” I should probably just not read it for my own sake

-Yes, I am the worst kind of person for mixing unit systems

https://www.brewpi.com/what-is-ideal-herms-coil-length-theory-experiments/

The further I got into the article the more the analysis motivated me to do my own. They neglect some of the true physics at play and treat many variables as fixed constants (friction coefficient and pump performance). While they do qualify that the results are system dependent they provide an optimum for the topsflo pump which I don't think as many people use.

The problem is that the "optimum" length of your coil is massively dependent on the performance of your pump and your individual system. So I set out to do a real analytical optimization of a HERMs coil for a set up that is more like the system that I brew on.

This section is about the calculation, feel free to skip:

If you want a good primer on fluid flow in pipes start here:

https://www.engineeringtoolbox.com/total-pressure-loss-ducts-pipes-d_625.html

In order to solve the D'Arcy-Weisbach Equation [hloss = λ (l / dh) (v2 / 2 g) ]

We need to solve for λ a.k.a The friction coefficient can be calculated by the Colebrooke Equation:

1 / λ1/2 = -2.0 log10 [ (2.51 / (Re λ1/2)) + (k / dh) / 3.72 ]

Because the formula is recursive we will have to solve this by iteratively. I used quartic iterations. Which should yield results many orders of magnitude more precise than the Nusselt number approximations use later on later on.

I took the pump curve from March for the 815-SS available here: http://www.marchpump.com/site/files/966/148215/489110/710019/815-SS.pdf

manually copied a few of the data point and and fit the curve.

Here is the pump curve fit:

I assume for this analysis that you have 2x 4ft silcone 1/2" hoses in addition to your HERMS coil running from your pump to the inlet and exit of the HERMS coil. For minor loss calculation I assumed 1 ball valve all the way open, 4 right angle fittings, and 4 cam-lock pairs. Minor loss coefficients (ξ) can be summed and added to the major losses.

hminor_loss = ξ v2/ (2 g) (1)

where

hminor_loss = minor head loss (m, ft)

From here we have the problem of solving for the steady state system operating point. Where we match the available head from the pump with loss in the system. This must be solved iteratively as well as the losses are a function of fluid velocity and the available head is a function of the fluid velocity as well. The iterative solver will stop once the apparent error is within 0.1%.

The script will also solve for both laminar (full and partially developed) and turbulent flows and adjust the Nusselt number, the friction factor, heat transfer coefficients accordingly. (turns out that most of the flow cases with this pump and reasonable coil lengths are sufficiently turbulent (Re>10,000) but for the pump in the article and some smaller pumps that is not the case.

I swept through lengths of HERMS coils from 1 to 70 ft as well as Mash to HLT temperature deltas of 1 to 20 degrees. The results follow.

END OF METHODOLOGY

The family of curves below is for the March 815-SS pump (one of the most common brewing pumps in the US) and assumes you have two 4ft lengths of 1/2" dia silicone hose with 90 elbows and cam lock fittings, a ball valve that is all the way open on your pump, 1/2" OD stainless steel tubing for the coil (0.035" wall), and that you can maintain constant temp in your mash tun (i.e. you can provide the same heat you are extracting).

One thing the article kind of neglected is that you don't necessarily want higher HERMs outlet temps. Heat transfer is maximized when the temperature difference between the two materials is large. What that means is that the closer your wort temp in the HERMs coil gets to the HLT temp the less heat transfer into that fluid you get for the same area of heat exchanger. Additionally they neglect the fact that you don't want the wort to get above 168F at all or you will start denaturing all of your amylases. On that note, you really want to do all you can to decrease the heat load on those amylases; therefore, you really want to have as small of a HERMs outlet temp differential as possible with a high flow rate*.

The first run I just spit out the power vs. coil length but neglected the outlet temp and you get the graph below, which just says you want as big of a temperature difference between your mash temp and the HLT tempas you can get with a coil length of about 20ft.

The second run I killed each curve when the outlet temp increased above 165F (74C) which is why you see that strange feather shape on the left. The straight line back to zero is just a bug in how I plotted it (sorry), the curve should terminate at the top. What this says is that your maximum "enzyme safe" temp delta is 9C (16F) and at that delta T you want about 18ft of coil (yields a flow rate of ~3.5gpm**). You can technically get a higher power system with the same pump if you have a very short coil but because that slope is so steep you run the risk of easily mis-estimating the head loss and not getting much power transfer at all or cooking your wort. To me, the risk is not worth the marginal power increase from the 9C delta set up. Also, that would need a very high flow rate and I think that would probably just result in a ton of grain bed settling, restricting your flow and then cooking your wort.

About those *'s, I'm not sure that 3.5 gpm is a reasonable flow rate for most mashes. I will have to see how bad that compacts my grain bed and report back. If it proves to be too high it will push the "optimum" coil length longer.

SO,

Lessons learned:

-You don't need the expensive 50+ foot coils everyone is trying to sell you

-Next time someone asks you what the optimum length is just tell them 18 ft

-Next time I see an article about brewing that relates to “engineering” I should probably just not read it for my own sake

-Yes, I am the worst kind of person for mixing unit systems

Last edited: