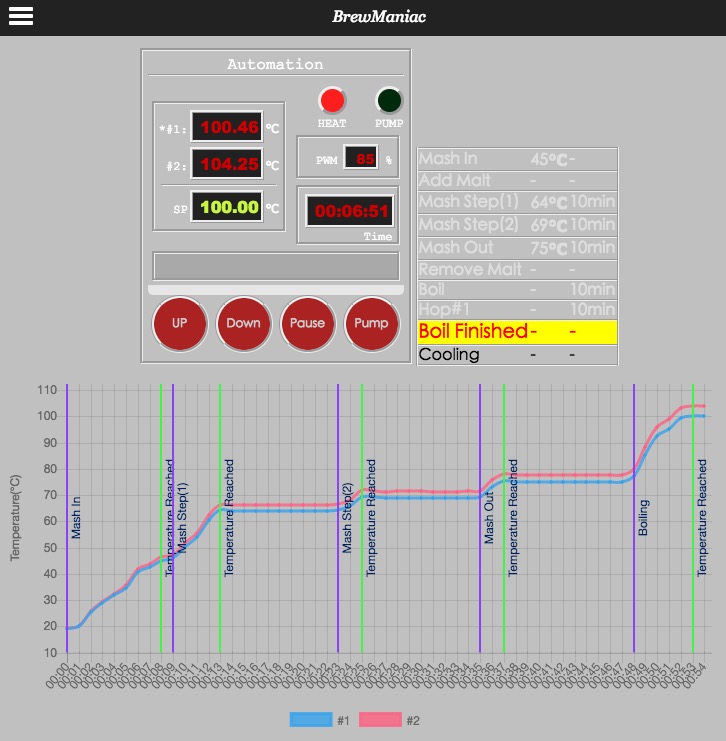

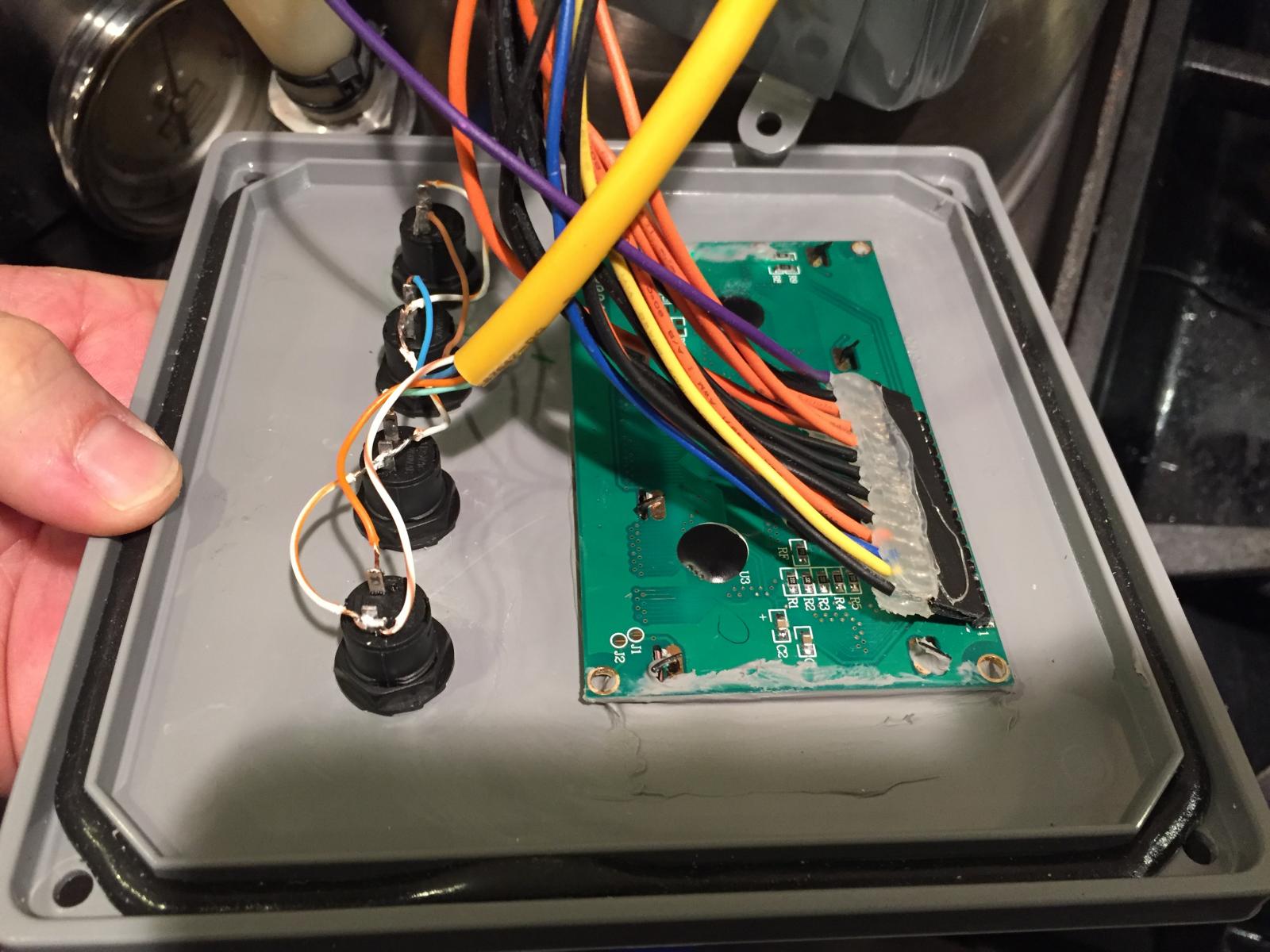

Not long ago I built a BrauSupply Clone system. I am going to convert it into an automated system using Open ArbBir and a Arduino Nano.

BrauSupply Clone w/12v pump

https://www.homebrewtalk.com/attachment.php?attachmentid=375665&stc=1&d=1478032600

https://www.homebrewtalk.com/attachment.php?attachmentid=375666&stc=1&d=1478032600

Thus far I have sourced and ordered all the components (I think).

10k Ohm Resistors

1k Ohm Resistors

470 Ohm Resistors

IN4007 Diodes

BC337 Transistors

IRFZ44 Rectifiers

3362P-1-103LF 10k Potentiometer

B008MU206C 12v Relay

DS18B20 Probe and Sensor

2 Pin Plug-in Screw Terminal Block

3 Pin Plug-in Screw Terminal Block

40Pin 2.54mm Single Row Straight Male Pin Header Strip

Copper Clad PCB

PCB Mount Mini Speaker - 8 Ohm 0.2W

20X4 Character LCD Module Display For Arduino

Arduino Nano V3.0 ATmega328

Assorted 3mm/5mm LEDS

Momentary Push Button Switches

Circuit Board Thermal Transfer Paper

Ferric Chloride

My sources have been:

https://www.homebrewtalk.com/showthread.php?t=540002&page=1

https://github.com/ArdBir

https://github.com/arzaman

I have worked on the PCB design as I couldn't figure out how to use the design in the Github to work with the toner transfer method. The main source for toner transfer methods was using the Arduino Uno. After extensive searching found this page http://www.piwo.org/topic/10829-sterownik-do-kadzi-zaciernej/page-4

It had this PCB design I could work with.

https://www.homebrewtalk.com/attachment.php?attachmentid=375672&stc=1&d=1478034120

After a few hours of PhotoShop, scanning, and a Sharpie Pen I ended up with a final PCB design.

https://www.homebrewtalk.com/attachment.php?attachmentid=375673&stc=1&d=1478034201

Getting the correct sizing on the print out for the PCB is my next hurdle.

Now I wait on components to trickle in.

Update:

Found a list of components for the build.

01 Arduino Nano

01 LCD 20x4 Blue background and White letters

01 mini size relay for 12V (not needed if used a SSR for pump)

01 Buzzer 12V

R8 - 120 Ohms

R2, R10, R11, R14, R15 - 1K Ohms

R1 - 2k7 Ohms

R4, R5, R6, R7 - 10k Omhs

R3, R9, R12, R13, R16 - 1M Ohms

P1 - 10k Ohms

D1, D2, D3 - 1N4007

Q1, Q2 - BC337

Q3, Q4 - IRFZ44N

08 Two Way PCB Mount Screw Terminals

02 Three Way PCB Mount Screw Terminals

01 Strip Line Connector Single Row Straight Terminals(come with 40 pins)

01 PCB sigle 11cm X 9cm

4 push-buttons as keypad

BrauSupply Clone w/12v pump

https://www.homebrewtalk.com/attachment.php?attachmentid=375665&stc=1&d=1478032600

https://www.homebrewtalk.com/attachment.php?attachmentid=375666&stc=1&d=1478032600

Thus far I have sourced and ordered all the components (I think).

10k Ohm Resistors

1k Ohm Resistors

470 Ohm Resistors

IN4007 Diodes

BC337 Transistors

IRFZ44 Rectifiers

3362P-1-103LF 10k Potentiometer

B008MU206C 12v Relay

DS18B20 Probe and Sensor

2 Pin Plug-in Screw Terminal Block

3 Pin Plug-in Screw Terminal Block

40Pin 2.54mm Single Row Straight Male Pin Header Strip

Copper Clad PCB

PCB Mount Mini Speaker - 8 Ohm 0.2W

20X4 Character LCD Module Display For Arduino

Arduino Nano V3.0 ATmega328

Assorted 3mm/5mm LEDS

Momentary Push Button Switches

Circuit Board Thermal Transfer Paper

Ferric Chloride

My sources have been:

https://www.homebrewtalk.com/showthread.php?t=540002&page=1

https://github.com/ArdBir

https://github.com/arzaman

I have worked on the PCB design as I couldn't figure out how to use the design in the Github to work with the toner transfer method. The main source for toner transfer methods was using the Arduino Uno. After extensive searching found this page http://www.piwo.org/topic/10829-sterownik-do-kadzi-zaciernej/page-4

It had this PCB design I could work with.

https://www.homebrewtalk.com/attachment.php?attachmentid=375672&stc=1&d=1478034120

After a few hours of PhotoShop, scanning, and a Sharpie Pen I ended up with a final PCB design.

https://www.homebrewtalk.com/attachment.php?attachmentid=375673&stc=1&d=1478034201

Getting the correct sizing on the print out for the PCB is my next hurdle.

Now I wait on components to trickle in.

Update:

Found a list of components for the build.

01 Arduino Nano

01 LCD 20x4 Blue background and White letters

01 mini size relay for 12V (not needed if used a SSR for pump)

01 Buzzer 12V

R8 - 120 Ohms

R2, R10, R11, R14, R15 - 1K Ohms

R1 - 2k7 Ohms

R4, R5, R6, R7 - 10k Omhs

R3, R9, R12, R13, R16 - 1M Ohms

P1 - 10k Ohms

D1, D2, D3 - 1N4007

Q1, Q2 - BC337

Q3, Q4 - IRFZ44N

08 Two Way PCB Mount Screw Terminals

02 Three Way PCB Mount Screw Terminals

01 Strip Line Connector Single Row Straight Terminals(come with 40 pins)

01 PCB sigle 11cm X 9cm

4 push-buttons as keypad