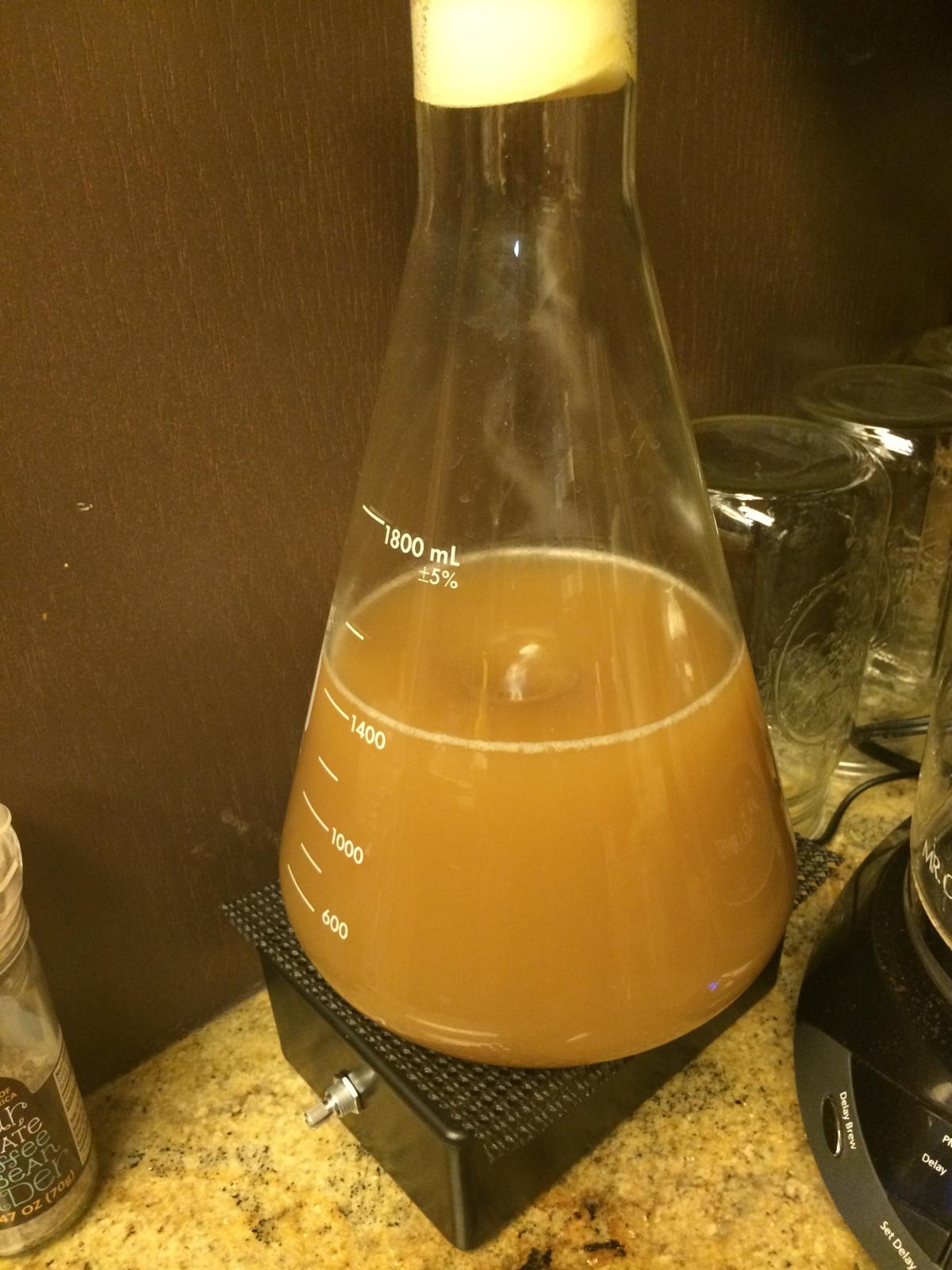

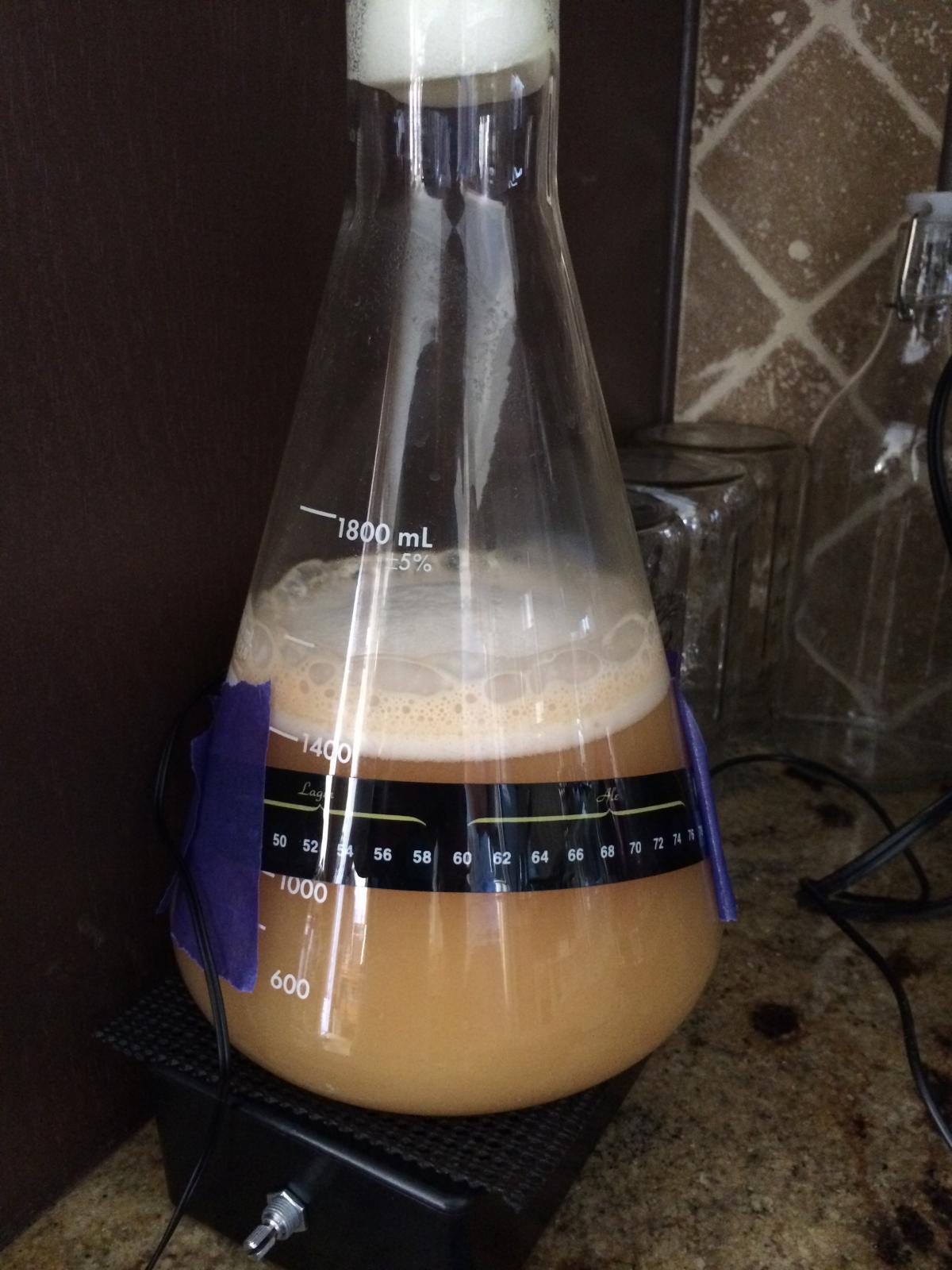

Do you want to go faster or slower? I made the same build and it can go so fast it throws the stirbar and can also send voltage so low it won't power the fan on. Realistically you don't need a whole lot more than a good medium pace swirl if you're just using it for yeast starters.

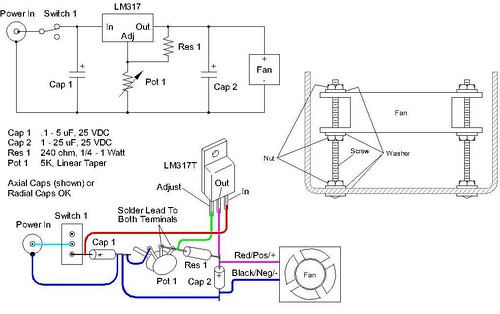

If you want more control over speed, I've heard you have to add a voltage regulator lm317.

If you want more control over speed, I've heard you have to add a voltage regulator lm317.