Hey guys,

I figured i would post up about some of the progress i have been making on my brew rig. It's going somewhat slow partially due to money and a little due to laziness.

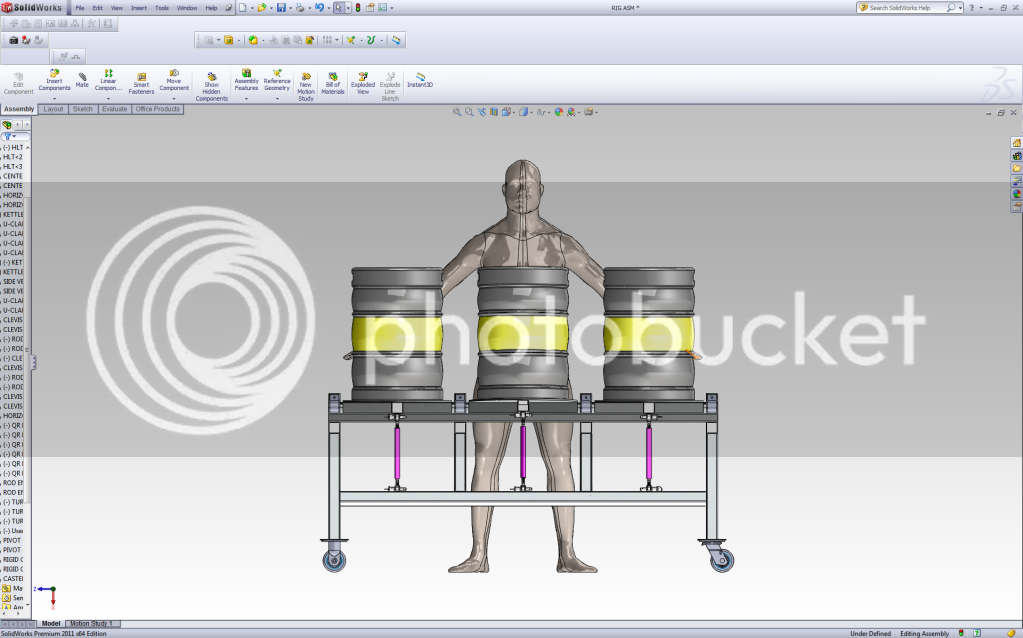

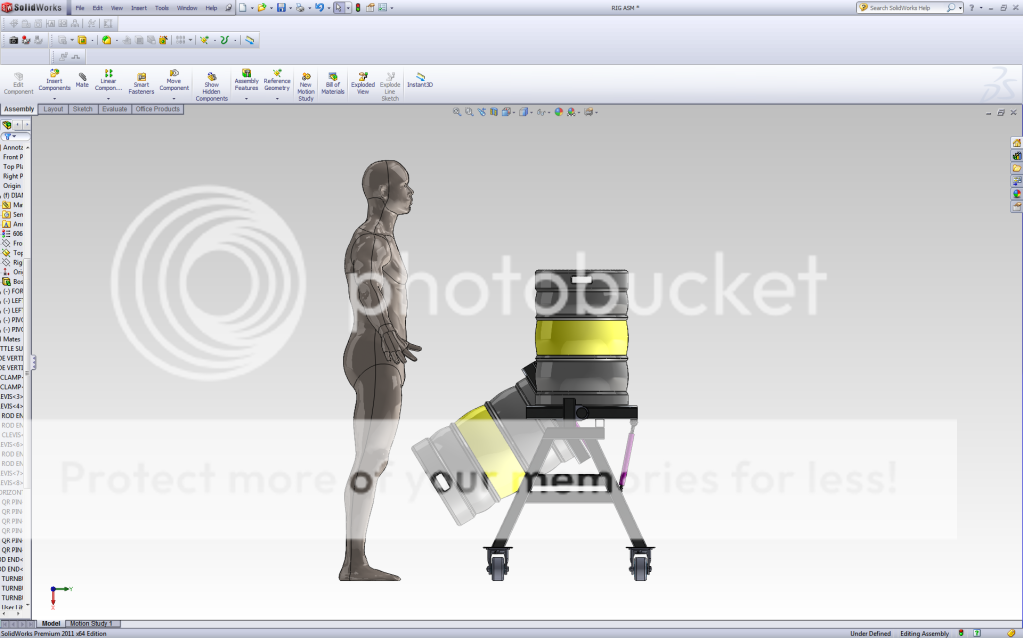

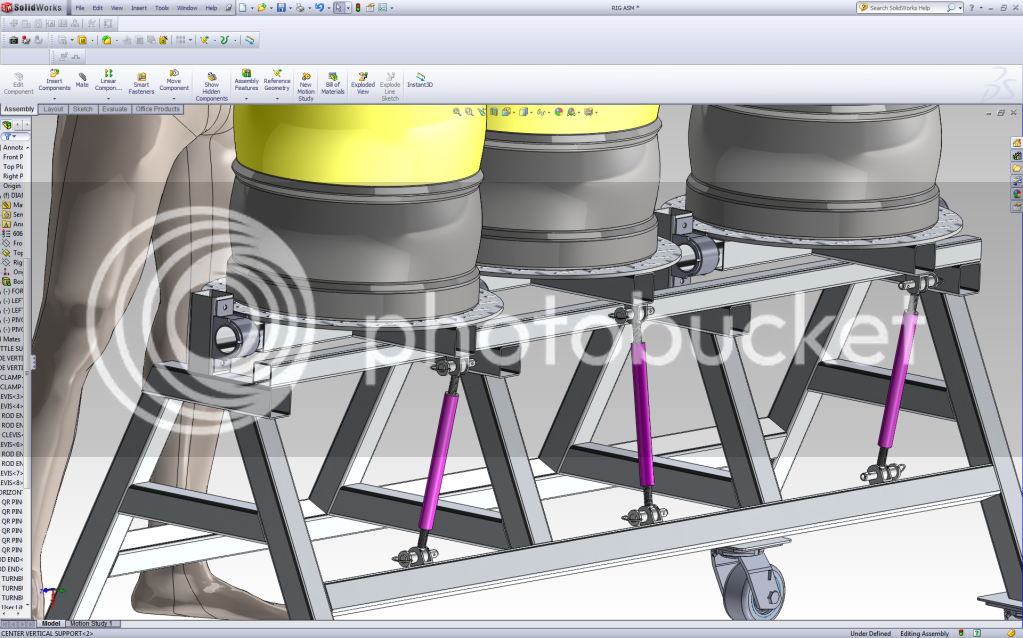

Anyway, I have a rough CAD model made for structural portion as it is designed so far:

That is just part of the work i have been doing. A lot more to come with control panel and stuff. I wanted it to look different than most other rigs, and it ended up looking like a sawhorse. I still think it looks good though.

All of the plumbing will be hard lines with disconnects on the sides and backs of all 3 vessels. That way i can unhook the turnbuckles and tip them forward to rinse them out.

Do you guys think its at a good height? the top of the kegs are at ~ 53"