So, not wanting to buy a fridge because it would be too easy, I decided to make a wort chiller by temperature controlling the swamp cooler approach. I did this more because it's possible, than because it's the best solution. I like to tinker.

Pros:

Cons:

I made up four temperature probes from stainless rod stock.

The thermometers I used are the Dallas/Maxim DS18S20's which a lot of people here use. These fit into the stainless probe with slight friction, so the fit is snug.

I sealed the ends with food safe epoxy.

I used the USB controller DS9420.

It all looks like this:

I had an old cooler which I fill with water and a bunch of half size frozen water bottles (not the big ones pictured.

The pump is connected to the temperature controller (Control Products 2 stage)

Temp controller probe will be attached to the side of the fermentor, and insulated a bit.

The drain pictured is a test setup, the final will be much closer to the wall. Variable height for variable fermentors.

Water is pumped when the controller activates, when the temp reaches set point it shuts off. Simple. Pump is a cheap aquarium type from Harbor Freight.

I have a temperature monitoring probe in the fermentor, attached to the side, and in the water bath. This is so I can see correlation over time and frequency of pump activation.

The rough setup looks like this (but will be much cleaner when done):

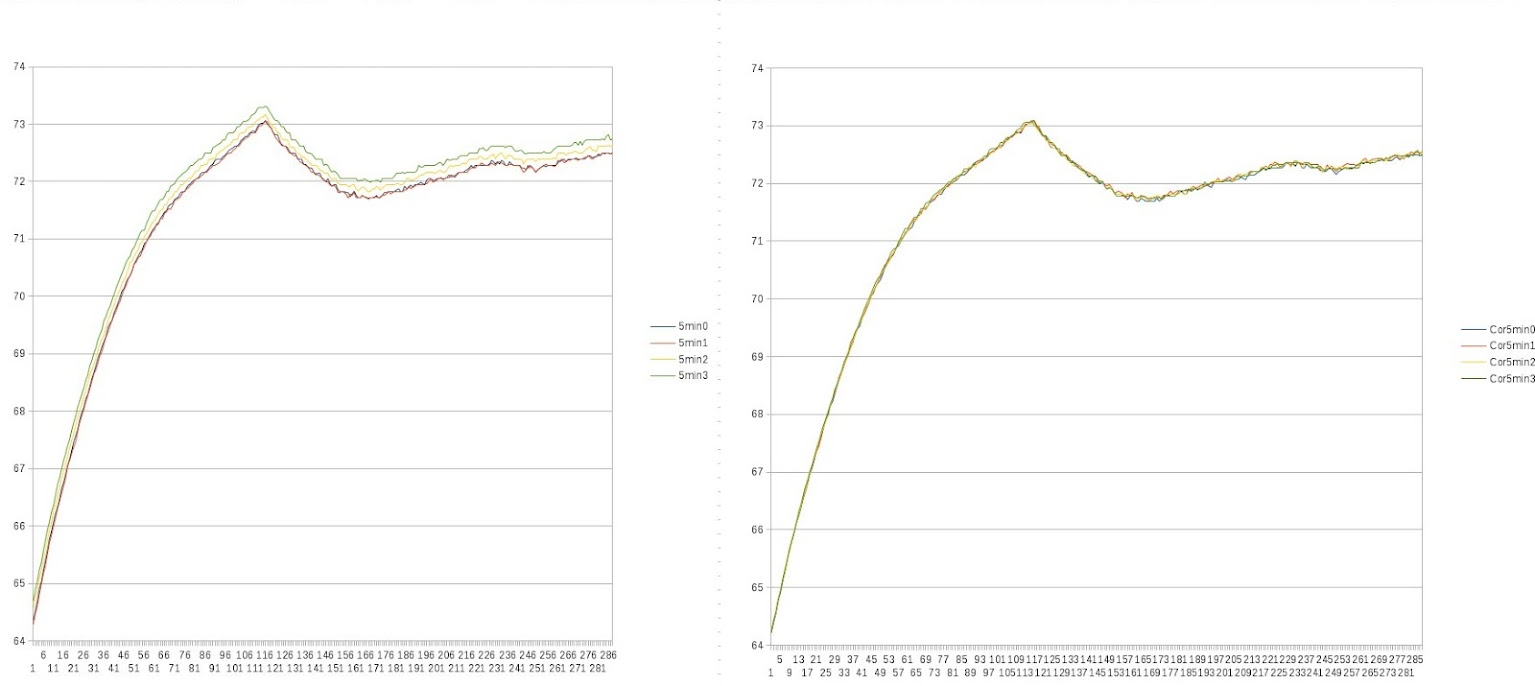

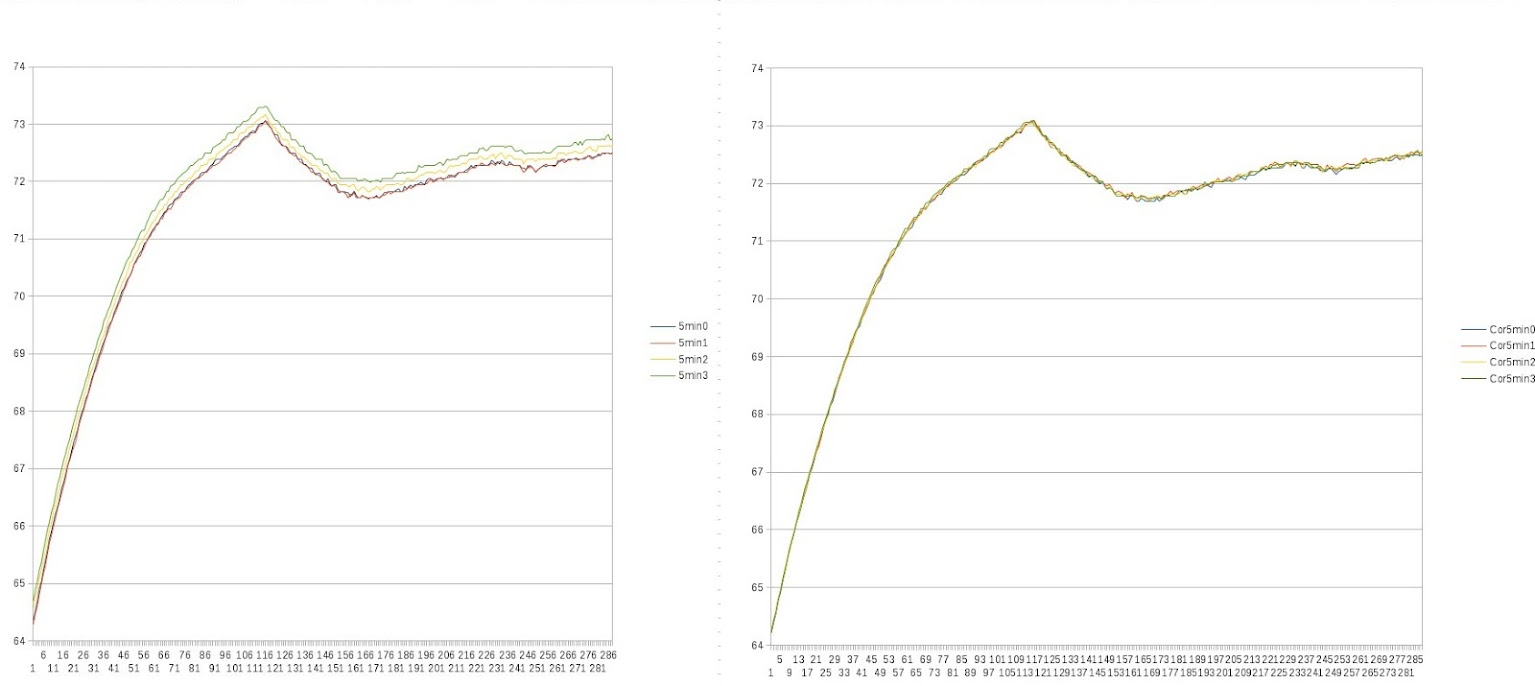

I calibrated the four DIY temperature probes against my reference brewing thermometer (with five involved, you have to pick one as reference). The correlation was very linear, and you can see the effect of making this correction over a 12 hour example set of data. 5 minute averages of per minute readings.

The data is logged to a database using RRDTool

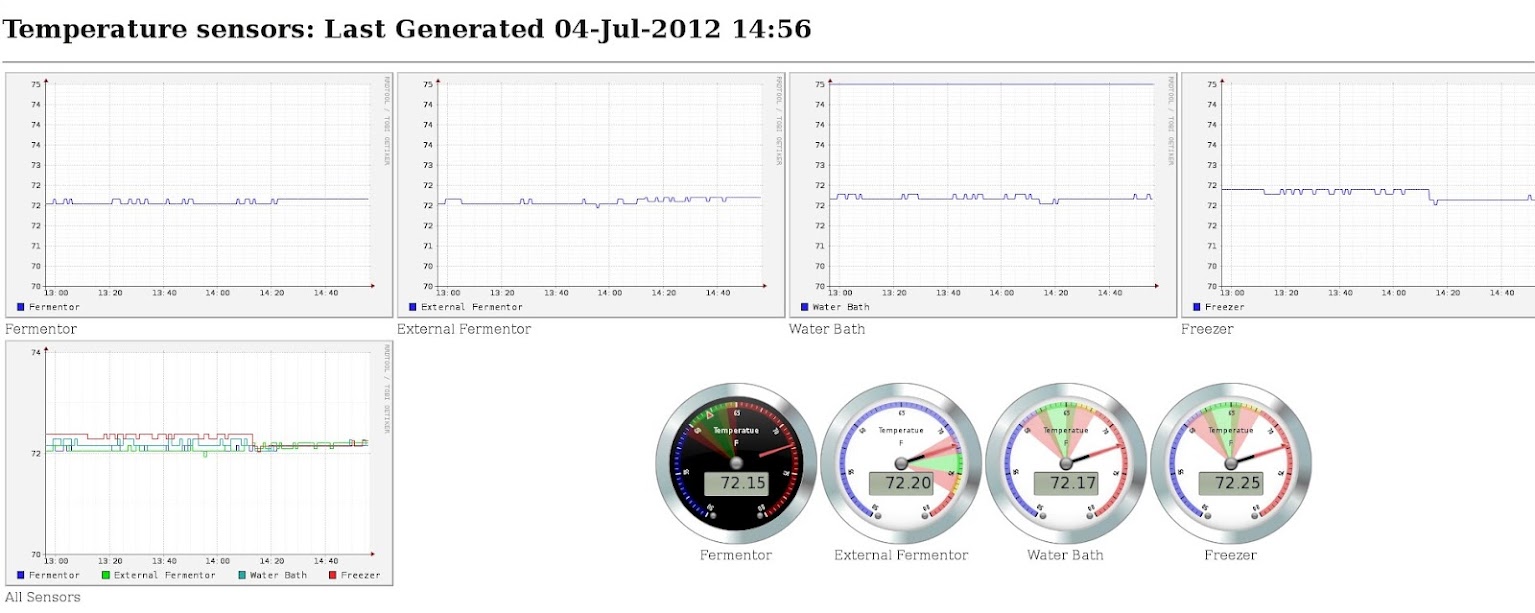

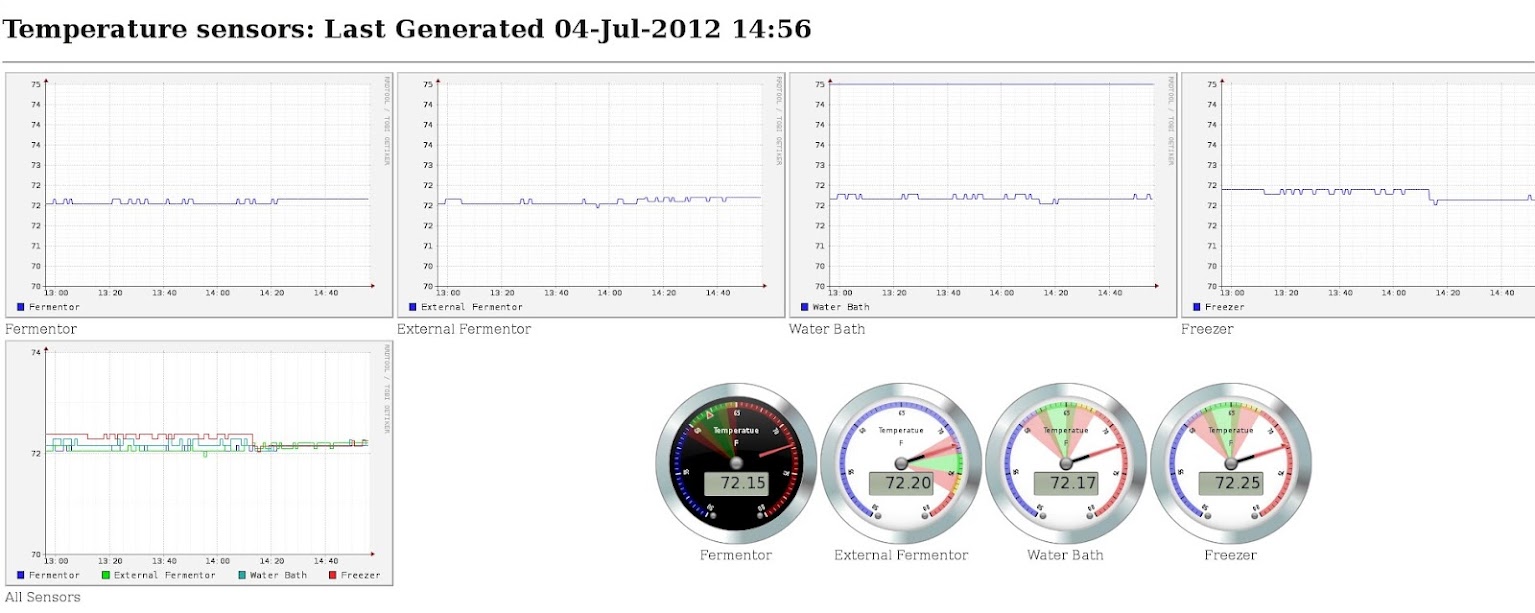

I then update a web page every minute with temp data graphs and gauges. I'm using RRDTool for the graph creation, and the slick html5 "Canvas Steel" gauges from Harmonic Code, which I saw first on this forum, along with a lot of these ideas.

I use Digitemp on a linux machine to pull the probe data, and some php scripts to do the temp correction, logging to the RRDTool database, and web page creation.

Later I'll make the page more dynamic so components refresh without reloading the page on a 60 second timer.

It's been fun. Hoping to set it all up and use it this weekend.

Pros:

- cheap

- Learn something new

- doubles as storage bins

Cons:

- ugly

- involves wiring, water, and coding, which can be a deadly mix, particularly coding

I made up four temperature probes from stainless rod stock.

The thermometers I used are the Dallas/Maxim DS18S20's which a lot of people here use. These fit into the stainless probe with slight friction, so the fit is snug.

I sealed the ends with food safe epoxy.

I used the USB controller DS9420.

It all looks like this:

I had an old cooler which I fill with water and a bunch of half size frozen water bottles (not the big ones pictured.

The pump is connected to the temperature controller (Control Products 2 stage)

Temp controller probe will be attached to the side of the fermentor, and insulated a bit.

The drain pictured is a test setup, the final will be much closer to the wall. Variable height for variable fermentors.

Water is pumped when the controller activates, when the temp reaches set point it shuts off. Simple. Pump is a cheap aquarium type from Harbor Freight.

I have a temperature monitoring probe in the fermentor, attached to the side, and in the water bath. This is so I can see correlation over time and frequency of pump activation.

The rough setup looks like this (but will be much cleaner when done):

I calibrated the four DIY temperature probes against my reference brewing thermometer (with five involved, you have to pick one as reference). The correlation was very linear, and you can see the effect of making this correction over a 12 hour example set of data. 5 minute averages of per minute readings.

The data is logged to a database using RRDTool

I then update a web page every minute with temp data graphs and gauges. I'm using RRDTool for the graph creation, and the slick html5 "Canvas Steel" gauges from Harmonic Code, which I saw first on this forum, along with a lot of these ideas.

I use Digitemp on a linux machine to pull the probe data, and some php scripts to do the temp correction, logging to the RRDTool database, and web page creation.

Later I'll make the page more dynamic so components refresh without reloading the page on a 60 second timer.

It's been fun. Hoping to set it all up and use it this weekend.

Last edited by a moderator: