Here ya go. They have a variety of 3/8' ones on this page.

http://www.mcmaster.com/#standard-sleeve-bearings/=mv3f9t

http://www.mcmaster.com/#standard-sleeve-bearings/=mv3f9t

So... they get a signal from a computer (cnc controller) that tells it how many steps to take and how fast those steps need to be? Hmm... I bet there are some Sparky's out there that could make it work. I however, am not one.

bluedog_Brewing said:I'm pretty sure that steppers motor require electronic commutation just like a brushless DC motor. If the motor has more than 2 or 3 wires, it usually requires an external controller to send pulses of power to each of the separate windings in the correct order and timing to run at a giving speed.

In other words, you cant apply a constant voltage and get a constant speed.

scutiger said:Sorry if this has been asked before, I've tried searching and came up with nothing definitive maybe I just missed it. I'm starting to look around for a used motor to power my mill, but I'm wondering what is the recommended minimum horse power of the motor? I see most people here have 1/3 hp or more, is that just because they're more available or is anything less just not optimal?

I used to have the same setup built from "Sam's Wortomatic" plans. Worked great. However, I think the GE gear motors are hard to come by unless surpluscenter.com has them back in stock now.

It depends on the size of the mill you're powering. Smaller 2 roller mills like the Barley Crusher can get by with 1/3 HP or less. Bigger mills with larger rollers (2") and/or 3 rollers will need at least 1/2 HP and preferably 1 HP. Torque and start up torque also matter (torque is a function of HP and RPM). Too low a torque means you may not be able to get the mill started; especially with grain already loaded into it. Getting a motor with a capacitor helps with that.

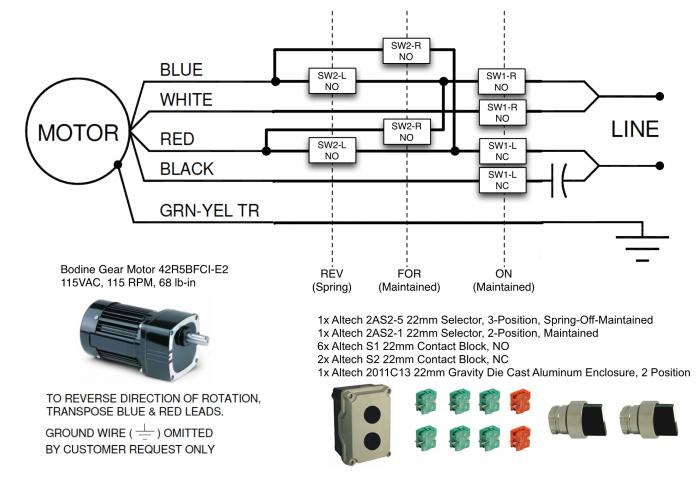

Cleaned up the control box since last post.

Bottom switch is reverse / off / forward.

E-Stop is probably overkill, but it looks cool.

.

Actually, there isn't anything I'd change. The simplicity of the design is one of its best features. Probably wont happen, but if anything, Id cut some windows in up-right and base aluminum pieces to lighten it up a little. Although theres not a lot to be gained since most of the weight is in the motor.After using your design for a while, is there anything you would do differently now? Any suggestions on things to look out for during the build?

I just found a gear motor on eBay (Bodine 42R5BFCI-E2; 115V, 115RPM, 68 lb-in).

curious what you found that for if you don't mind my asking. I took a look and about the cheapest one I've found is a bit over $200 and escalates rapidly from there. That about the going rate?

curious what you found that for if you don't mind my asking. I took a look and about the cheapest one I've found is a bit over $200 and escalates rapidly from there. That about the going rate?

You can use this one for less, same specs.

http://www.ebay.com/itm/BODINE-GEAR...470?pt=LH_DefaultDomain_0&hash=item27d44bfda6

Cheers,

ClaudiusB

That's the same model I got, from the same vendor. I got the $99 version as it was "new" (it did show some scrapes/rust however)

Care to share details, pics of this?. . . which I use as a mash mixer .

You can use this one for less, same specs.

http://www.ebay.com/itm/BODINE-GEAR...470?pt=LH_DefaultDomain_0&hash=item27d44bfda6

Cheers,

ClaudiusB

I'm not too knowledgeable about motors so wondering would I need anything other than a Lovejoy coupler and mounting bracket to run my mill with this? Also, not seeing the RPMs?

Thanks in advance for any advice.

I'm not too knowledgeable about motors so wondering would I need anything other than a Lovejoy coupler and mounting bracket to run my mill with this?

Also, not seeing the RPMs?[...]

Motor RPM 115 and you need a 15 uF capacitor.Don't buy the motor coupling until you have the motor and mill to get the shaft size.

This gives you more coupling option, besides the Lovejoy.

If I get the chance tomorrow I look up the capacitor for you.

Cheers,

ClaudiusB

Motor RPM 115 and you need a 15 uF capacitor.Don't buy the motor coupling until you have the motor and mill to get the shaft size.

This gives you more coupling option, besides the Lovejoy.

If I get the chance tomorrow I look up the capacitor for you.

Cheers,

ClaudiusB

You wouldn't happen to have a source with a good price for that gearmotor? The one I'm using to mix works fine but is pretty noisey. Got it cheap on eBay several years ago. It's 30RPM, 58 in-lb start, 90 in-lb run.Bodine gear motor

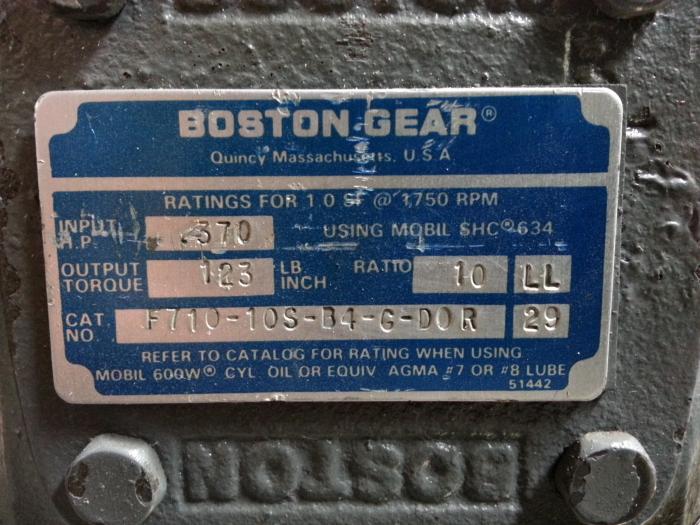

HP=1/9

RPM=26

Torque=146 lb-in

Not currentlyYou wouldn't happen to have a source with a good price for that gearmotor?

The one I'm using to mix works fine but is pretty noisey.

Not currently

As soon I see one I will let you know.

I put you on my to do list

Enter your email address to join: