ClaudiusB

Well-Known Member

DoneIf you would be so kind as to put me on that to do list I'll be very grateful. I'll continue to do some searches myself, but for the next month am too busy with other projects. cheers, JD

DoneIf you would be so kind as to put me on that to do list I'll be very grateful. I'll continue to do some searches myself, but for the next month am too busy with other projects. cheers, JD

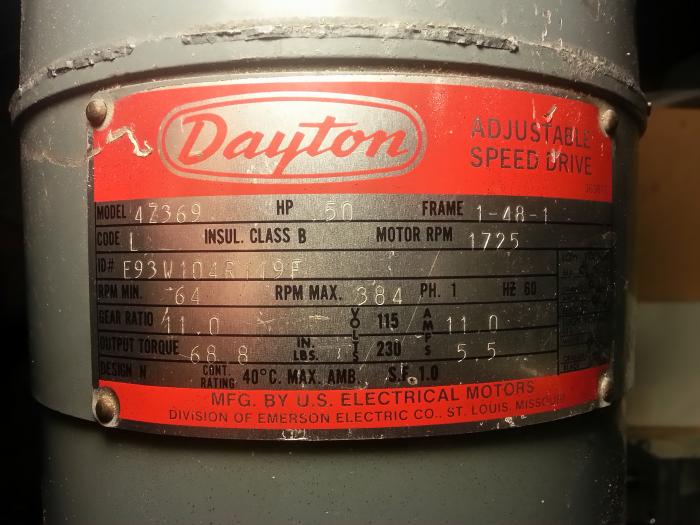

I'm not too knowledgeable about motors so wondering would I need anything other than a Lovejoy coupler and mounting bracket to run my mill with this? Also, not seeing the RPMs?

Thanks in advance for any advice.

You may want to get a switch if you want to be able to reverse the motor during normal operation; see my earlier post for what I am putting together.

I got the same model motor from the same ebay seller. It came with a capacitor and die cast terminal box. The capacitor is available from Bodine for $9 in case you need to order one.

PDF of the motor mechanical drawings is attached below; the output shaft is 0.75in. I got a Lovejoy spider coupler at Amazon.com to connect to my MM2 2.0 grinder, which has a 0.5in shaft:

Lovejoy 10621 Size L-AL 075 Solid Type Jaw Coupling Elastomer Spider, SOX/NBR Rubber, 1.75" OD, 0.44" Elastomer Length, 90 in-lbs Nominal Torque

Lovejoy 10685 Size L075 Standard Jaw Coupling Hub, Sintered Iron, Inch, 0.5" Bore, 1.75" OD, 0.82" Length Through Bore, 227 in-lbs Max Nominal Torque,

Lovejoy 10690 Size L075 Standard Jaw Coupling Hub, Sintered Iron, Inch, 0.75" Bore, 1.75" OD, 0.82" Length Through Bore, 227 in-lbs Max Nominal Torque

The motor I got was actually an "OEM special" version of the model and has a different wiring schematic vs. what is on the Bodine website. Bodine support sent me the correct wiring diagram, attached below.

Borgstrom,

I just received my Bodine OEM motor today and had a question on the wiring. The diagram shows 5 wires but mine only has 4; blue, red, white and black. My plan was to use the diagram on Sam's Wort-O-Matic site but I'm a little confused now. How did you wire yours?

Thanks

WoodHokie4 said:Anyone have any experience with this type of grinder? If the mechanics worked for malts, it wiuldnt be hard to motorize it

What you have there is a corona mill. Works great for grinding nixtamalized corn kernels into masa dough. It will pulverize your malt into flour and is only recommended as a last resort for malt. I do not think you will get a satisfactory crush for all grain with this mill though I know folks will contest the subject.

Not worth the effort to motorized that unless you're trying to make tortillas. Also, when set at finest setting, you can get some metal pieces into your corn. I'm interested in a better mill of corn, as these things IMHO are garbage.

TD

sar_dog_1 said:Has anybody ever tried this?????? I tore down a heavy duty porter cable model 725 portable band saw for its motor. The only info I could find that on slow setting it goes 195rpm and fast speed it goes 245 with a 90 deg worm drive. Horse power is questionable. The only thing I could find is when I tore apart the trigger which had a label of 1 HP. Is this the HP of the saw motor or just what that switch is capable of? Anyway I figure if ppl are using drills then this should work. It can cut metal 3 inches thick. Thoughts anyone??

Motor or girlfriend?

[...]1 HP is more than enough, and I do not believe that electrical switches are rated for HP, only voltage and amperage mainly. [...]

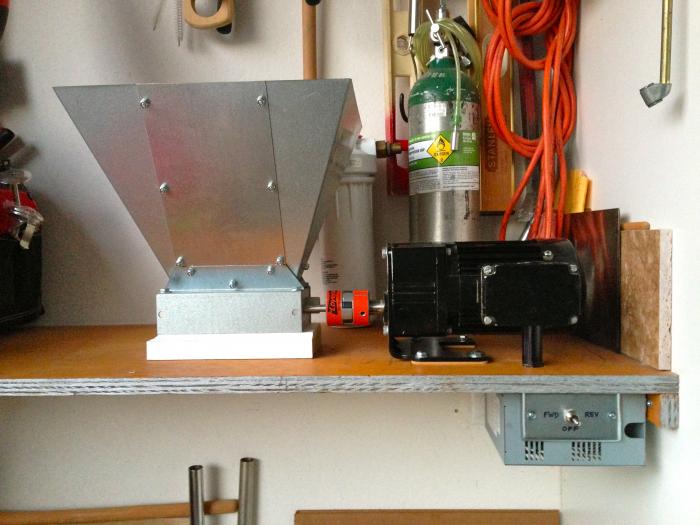

Nice! Here's mine....

^^^^^^

You. Must. Provide. Specs!

That thing is WAAAAAY too much of a beast to leave us hanging like you did!

Enter your email address to join: