BIAB does not have to have lower efficiency than other methods, and depending on process, may actually have higher efficiency than some non-BIAB processes.

You need to understand a bit about the factors that influence efficiency to understand how BIAB stacks up against alternatives.

Mash efficiency - how much of the potential extract (sugars, proteins, plus other minor components) in the grain makes it into your boil kettle, is the product of conversion efficiency and lauter efficiency. Conversion efficiency is a measure of how much of the potential extract in the grain is actually created as real extract in the mash. Lauter efficiency is a measure of how much of the extract created in the mash makes it into the BK. Brewhouse efficiency is mash efficiency reduced by loss of extract (wort volume) that is left behind going from the BK to fermenter.

Conversion Efficiency = Extract Actually Created in Mash / Maximum Potential Extract of Grain.

Lauter Efficiency = Extract in Boil Kettle / Extract Actually Created in Mash

Mash Efficiency = Extract in Boil Kettle / Maximum Potential Extract of Grain

Mash Efficiency = Conversion Efficiency * Lauter Efficiency

Brewhouse Efficiency = Mash Efficiency * Volume in Fermenter / Post Boil Volume

The things that can reduce conversion efficiency are crush being too coarse for starch gelatinization to complete during the mash, mash time being too short for gelatinization and hydrolysis of the starch to complete, mash temp being way out of range (either high or low), and pH being way out of range (either high or low.)

Hydrolysis is the chemical reaction that chops up long starch chains into fermentable sugar and unfermentable dextrin. But before hydrolysis can occur, the starch chains need to be (at least partially) gelatinized, and complete hydrolysis requires complete gelatinization. This is where crush size can affect conversion efficiency. Small grits (fine crush) gelatinize faster than large grits (coarse crush), so finely crushed grain can complete gelatinization, and thus complete conversion, faster than coarsely crushed grain. Double crushing can give you a finer crush than single crushing.

But to know if finer crush will improve your efficiency, you have to know whether or not your conversion efficiency is significantly below 100%. If your crush and mash conditions already give you ~100% conversion, then a finer crush will not improve your efficiency. Incomplete conversion is however, a common situation for home brewers, and crush often helps.

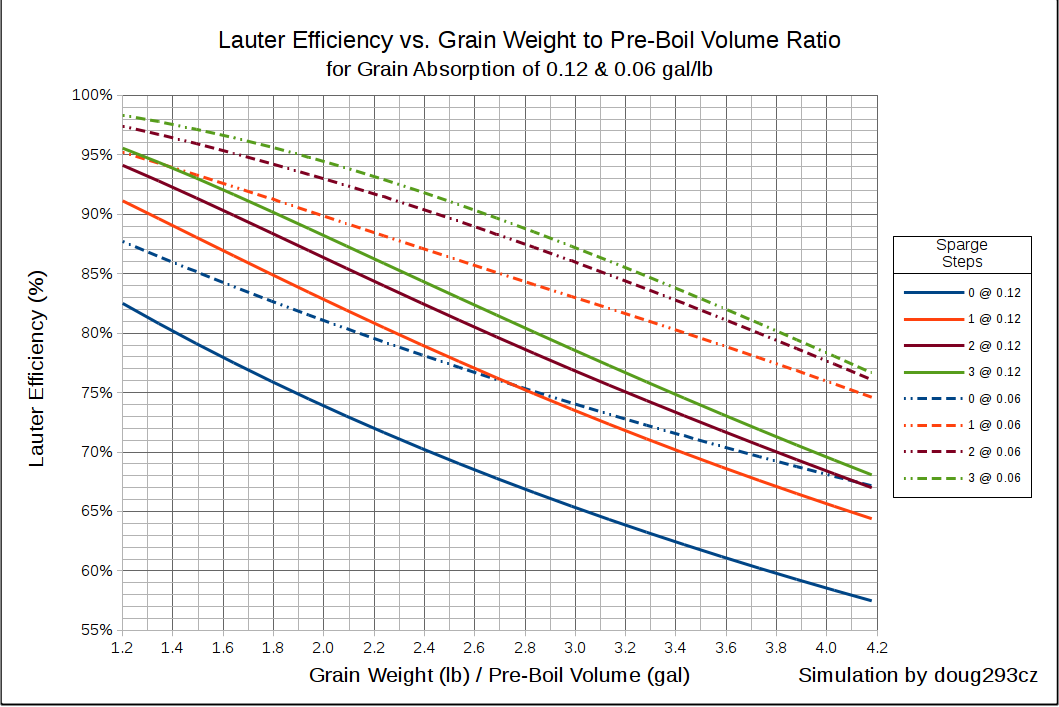

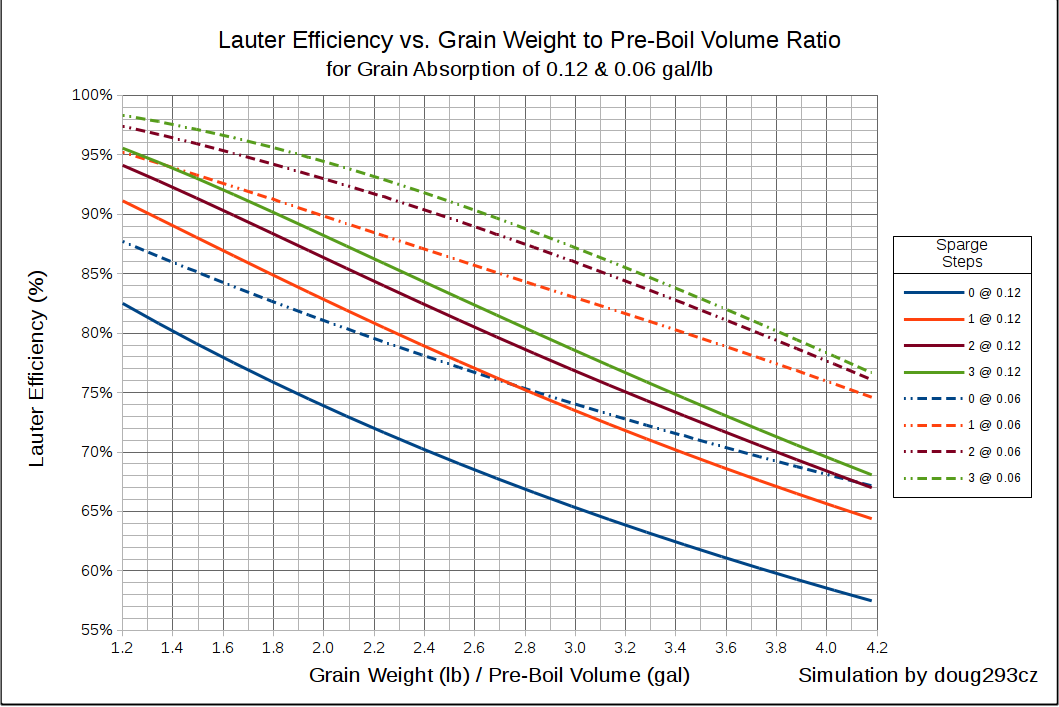

Lauter efficiency is equal to 100% minus % of extract retained in the spent grain. The amount of extract retained in the spent grain is determined by the concentration of extract in the wort retained in the spent grain, and the volume of wort retained in the spent grain. Sparging (rinsing the spent grain with plain water) reduces the concentration of extract in the retained wort, thus improving lauter efficiency. Reducing the volume of wort retained in the spent grain (such as by squeezing the bag), is another way to improve lauter efficiency. Larger grain bills absorb and retain more wort so reduce lauter efficiency compared to smaller grain bills. The chart below shows how lauter efficiency changes based on sparge process (batch sparge only), grain absorption rate (gal/lb), and grain bill weight / pre-boil volume (10 lbs of grain and 6.5 gal pre-boil is equivalent to 20 lbs of grain and 13 gal pre-boil for lautering):

In order to determine whether your lower than expected mash efficiency is due to incomplete conversion, or inefficient lautering, you need to calculate the two factors that combine to determine mash efficiency. You need to know which (or maybe both) is low in order to know what to change in your process to improve things.

Adding a sparge will improve your lauter efficiency. Dunk sparging - placing the drained bag in a bucket of fresh water and stirring well - is a form of batch sparging. Draining the bag more completely, or squeezing the bag will also improve your lauter efficiency, as they reduce the grain absorption rate.

If you collect the following data, you can do the calculations to determine both conversion and lauter efficiency:

- Grain Bill Weight

- Weighted Average Grain Potential (points per pound, or %) - 37 pts/lb or 80% can be used as a rough estimate if you don't have detailed potentials for all of your grains

- Strike Water Volume (the water volume for mashing)

- Pre-Boil SG

- Pre-Boil Volume

- Post-Boil SG and Volume can be substituted for Pre-Boil, but you can't mix Pre and Post data

If you can post the above data for one or two of your brew sessions, I can calculate the conversion and lauter efficiencies you actually achieved, and give you some guidance on what changes can improve your efficiencies.

Brew on