Does anyone know of some circuit diagrams that use STC1000's and electromechanical relays? I'm on a super-tight budget, don't need a lot of whistles, bells, and buzzers, and have some of the parts already.

my STCs are 220v.

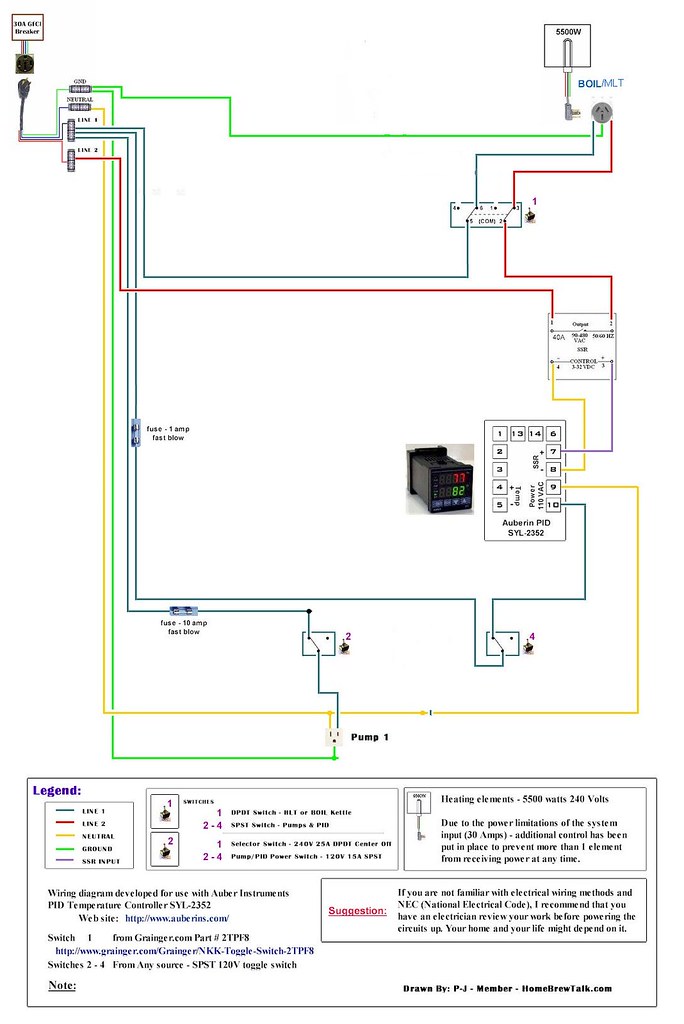

I'm just looking for some diagrams to give me ideas so I can use/butcher/modify them for my own use. I'm presently using some from PJs collection, and have done some extensive white-out work to make them close to what I want.

Maybe if I had a small diagram of how an electromechanical relay is wired into the system between the 240v output of the STC and the 4500W element, that would suffice. I think I've got everything else just the way I want it.

TIA

my STCs are 220v.

I'm just looking for some diagrams to give me ideas so I can use/butcher/modify them for my own use. I'm presently using some from PJs collection, and have done some extensive white-out work to make them close to what I want.

Maybe if I had a small diagram of how an electromechanical relay is wired into the system between the 240v output of the STC and the 4500W element, that would suffice. I think I've got everything else just the way I want it.

TIA