First, I would like to thank P-J and all the others for all their hard work.

I finally finished reading this entire thread and have a question to ask before my brain trips its GFCI...

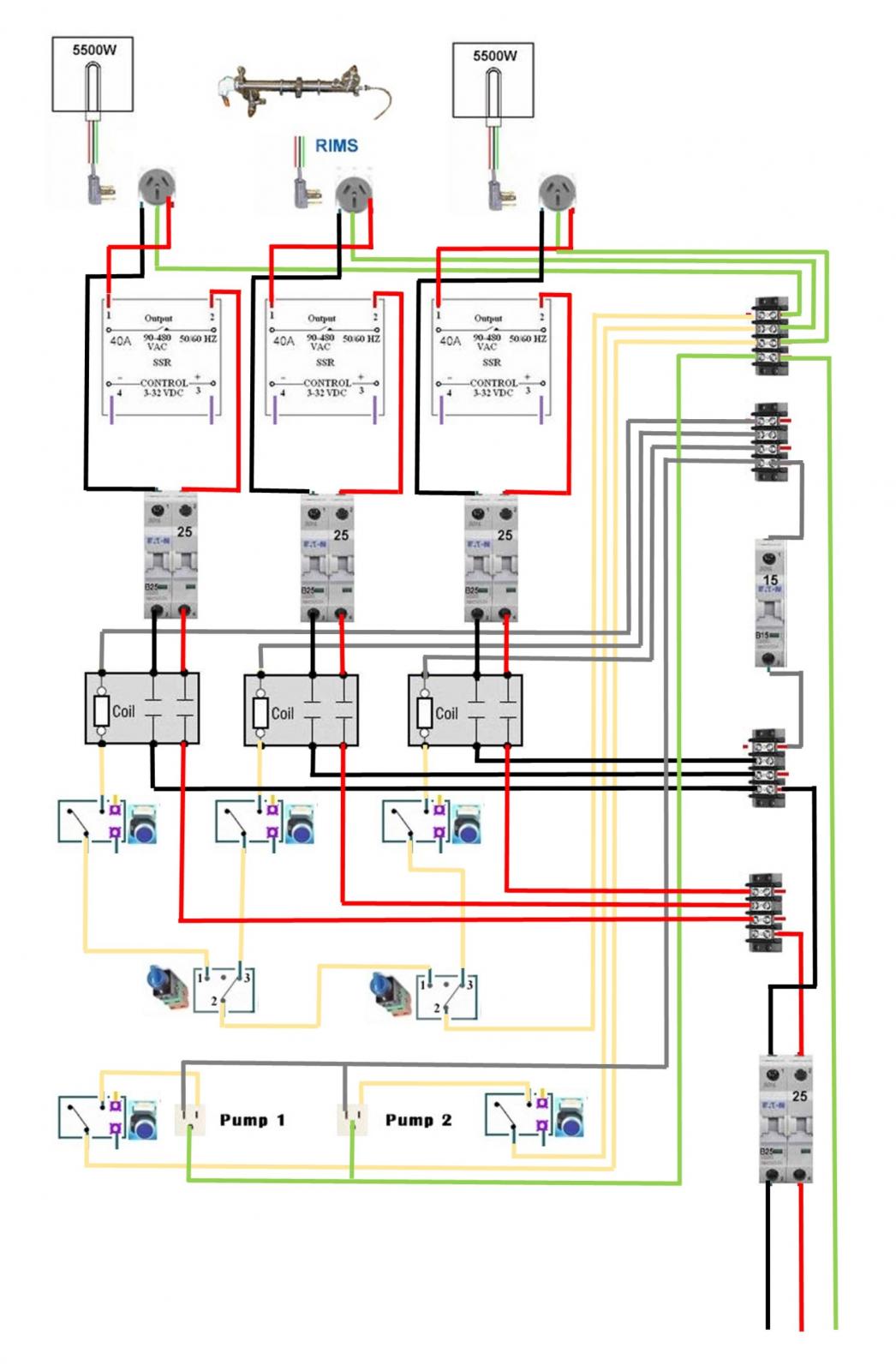

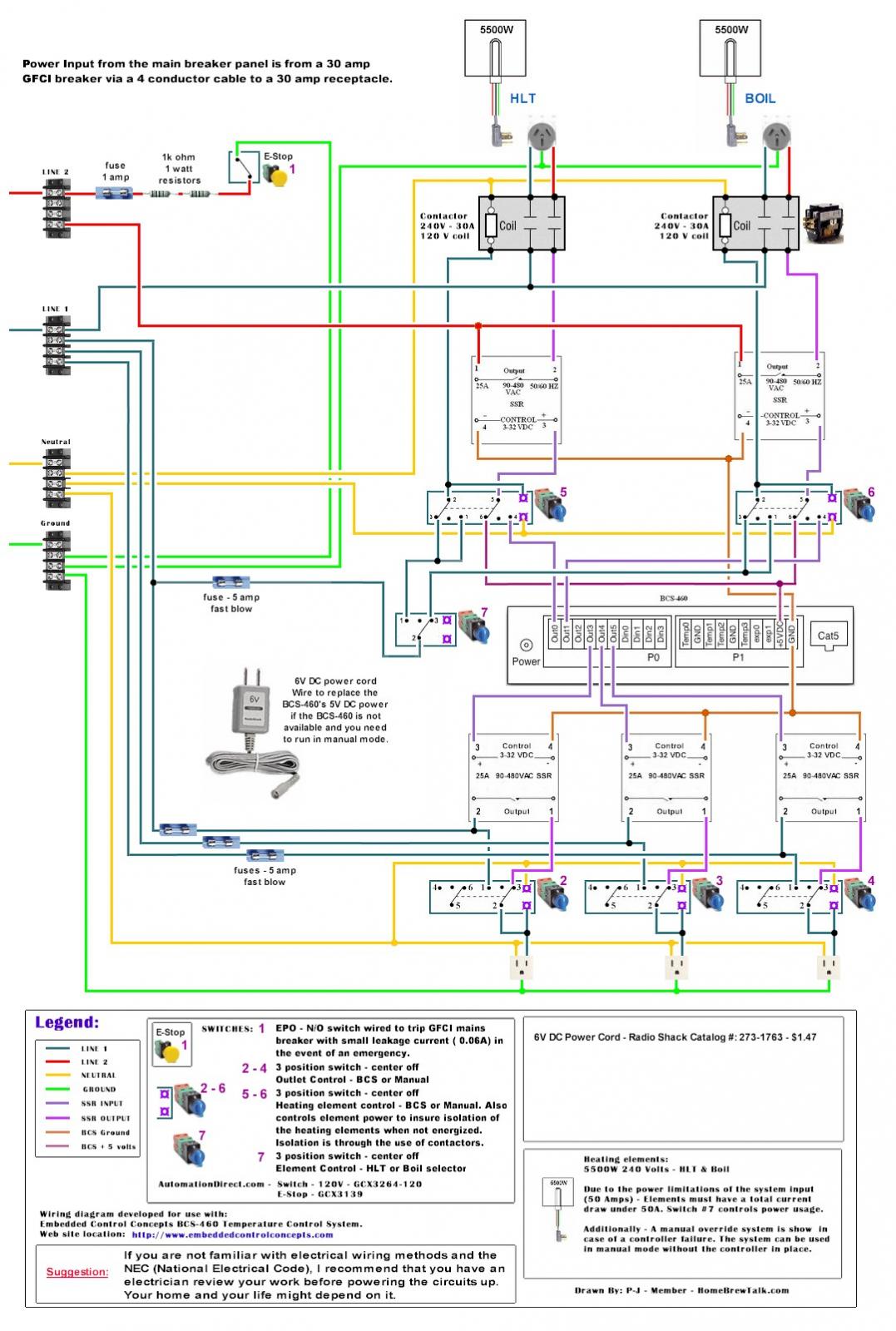

I'm planning on building a RIMS with two pumps, one PID (SYL-2352), with 1500W or less element (120V) and fancy illuminated switches.

Hey, I'm a retired Air Traffic Controller, and after spending the better part of my adult life in a dark room without any windows, I've grown accustomed to fancy illuminated switches.

Anyway, I like P-J's "Auberin-wiring1-SYL-2352-basic3a-RIMS" diagram. I believe that was the one he made for SweetCell.

In the diagram the R30A mini relay has the coil wired to the "heat" switch and RIMS element (left side of relay).

The right side is wired to the RIMS element and the SSR.

Looking at the photo of the R30A relay, the connections on the right are COMM, NO and NC.

Is the RIMS and SSR wires connected to "N Open" or "N Closed" position along with the COM position?

P-J, hang in there. I may not be as old as you but I'm pretty close behind.

So don't make any sudden stops.

Any help is greatly appreciated.

I'm not fast anymore...I'm now half-fast!

View attachment 290051

Auber R30A mini relay

View attachment 290052