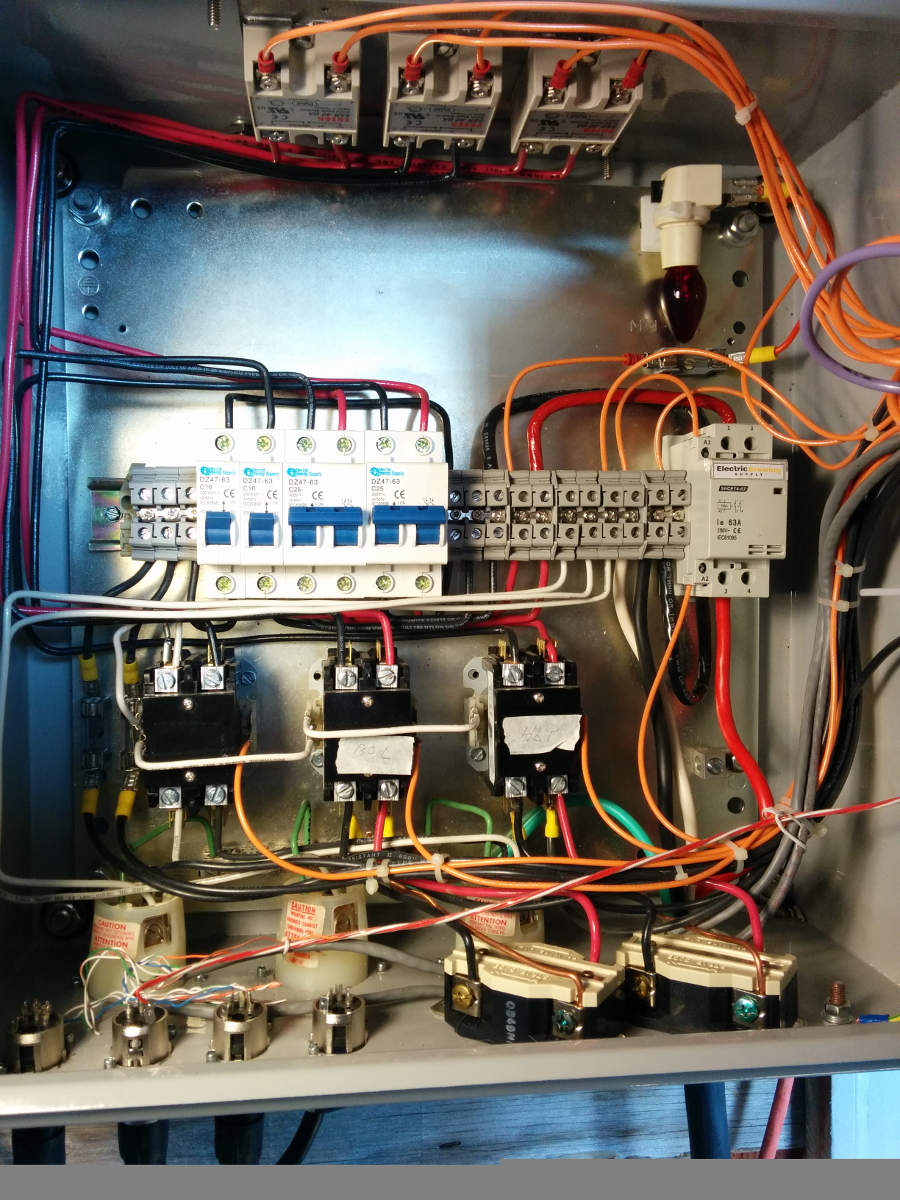

Correct me if I'm wrong but it looks like when you switch on the contactor your unintentionally getting 120v from line 1 through your element and LED.

Using a 240v LED you could try wiring it up like the 5500 2 Element 30a EStop PID diagram.

Using a 240v LED you could try wiring it up like the 5500 2 Element 30a EStop PID diagram.