Im a long time browser but this will be my first post of hopefully many write-ups on some of my brewing projects. Ive been meaning to write this up for a while now and I finally have the time.

Keezer Build

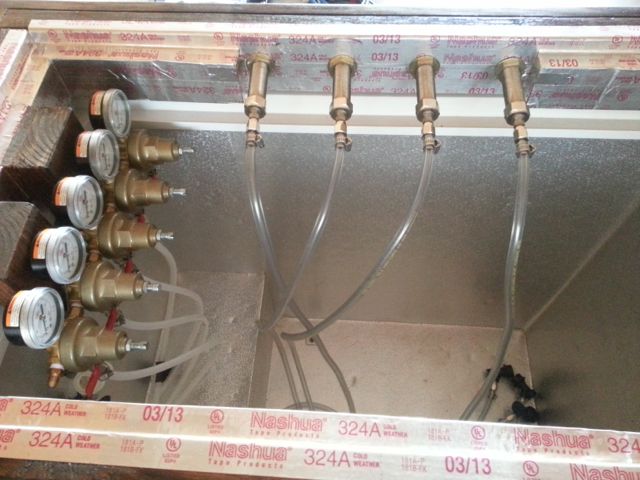

After looking at many examples on homebrewtalk I decided on a base design of a four tap system with an external CO2 tank. I wanted individual pressure control of the 4 kegs and a fifth regulator connected to a bulkhead for an external regulated CO2 connection to use while bottling and force carbonating. I found a 7 cu ft GE freezer from craigslist in great shape for the right price. I also found the five taprite secondary regulators on craigslist for $20 each. The guy had a box full of them and was nice enough to pull out the best condition ones for me. I lucked out on the price of the regulators and it allowed me to stay with the five regulator setup without buying a premade custom block. Getting all of the regulators to line up in the block and maintain a good seal with the nipples took a little futzing with, but in my opinion it ended up working out well.

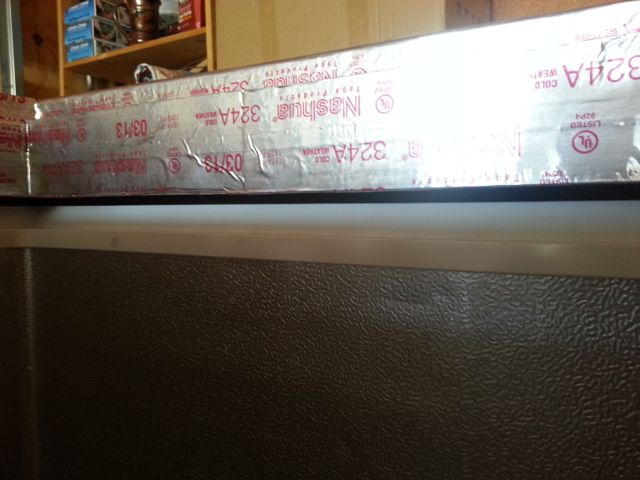

My next step was the choosing a faucet and shank length. I went with the Perlick 525SS with 6 shanks. The build was almost a year ago so the newer faucet they released, cant remember the model, was not available. I understand some people have had leaking problems with the 525SS overtime but from what I understand Perlick has stood behind their product and replaced defective units and seals. In hind site I should have gone with shorter shanks but overall I am very happy with the end result.

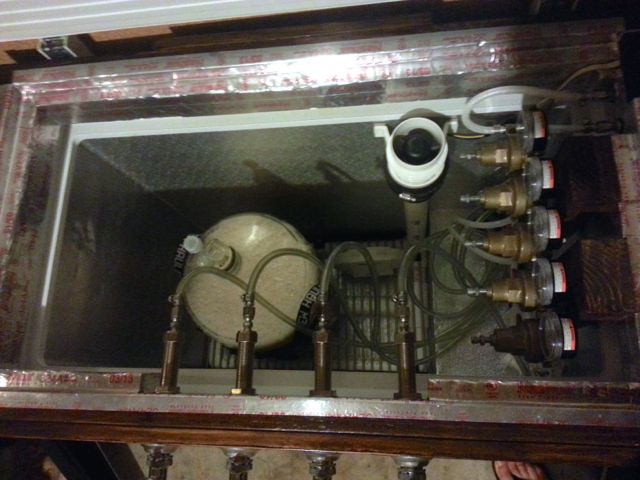

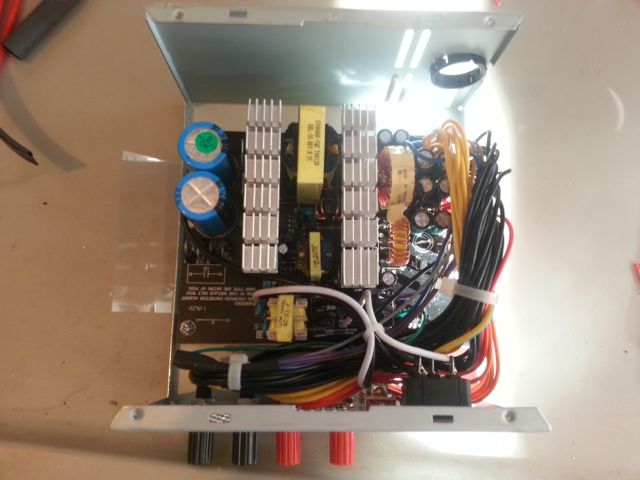

I originally used an Eva-Dry E-500 with a 120mm fan on the compressor shelf blowing across the keezer, but I found when I had multiple kegs on tap I started having moisture buildup on the far side opposite the fan. I recently finished a new airflow set up that is working perfectly. I got the idea from here. I am now using the same Eva-Dry E-500 with a new fan / PCV setup. It is an inline bilge fan, running on a modified computer PSU, adapting to 1-1/2" PVC. I recommend not gluing the PVC because you can re-aim the airflow if necessary and it makes cleaning up if you have a keg leak easier. The rack is a folding stainless drying rack made to place over a kitchen sink for drying dishes (home depot). I cut the tubes to length with standard tube cutter. I now have zero moisture problems even if I use the keezer as a fermentation chamber. I highly recommend this approach for moisture build up.

I am planning on doing a write up on the keg / carboy / line cleaner after I change a few things to make it even better. It performs beautifully but I want to be able to disconnect the vertical pipe to make storage, cleaning, and flushing easier.

See attached excel docs for parts list and pricing. A big thanks goes to homebrewtalk for all the quality posts that made researching my options much easier.

Cheers,

Ben

Keezer Build

After looking at many examples on homebrewtalk I decided on a base design of a four tap system with an external CO2 tank. I wanted individual pressure control of the 4 kegs and a fifth regulator connected to a bulkhead for an external regulated CO2 connection to use while bottling and force carbonating. I found a 7 cu ft GE freezer from craigslist in great shape for the right price. I also found the five taprite secondary regulators on craigslist for $20 each. The guy had a box full of them and was nice enough to pull out the best condition ones for me. I lucked out on the price of the regulators and it allowed me to stay with the five regulator setup without buying a premade custom block. Getting all of the regulators to line up in the block and maintain a good seal with the nipples took a little futzing with, but in my opinion it ended up working out well.

My next step was the choosing a faucet and shank length. I went with the Perlick 525SS with 6 shanks. The build was almost a year ago so the newer faucet they released, cant remember the model, was not available. I understand some people have had leaking problems with the 525SS overtime but from what I understand Perlick has stood behind their product and replaced defective units and seals. In hind site I should have gone with shorter shanks but overall I am very happy with the end result.

I originally used an Eva-Dry E-500 with a 120mm fan on the compressor shelf blowing across the keezer, but I found when I had multiple kegs on tap I started having moisture buildup on the far side opposite the fan. I recently finished a new airflow set up that is working perfectly. I got the idea from here. I am now using the same Eva-Dry E-500 with a new fan / PCV setup. It is an inline bilge fan, running on a modified computer PSU, adapting to 1-1/2" PVC. I recommend not gluing the PVC because you can re-aim the airflow if necessary and it makes cleaning up if you have a keg leak easier. The rack is a folding stainless drying rack made to place over a kitchen sink for drying dishes (home depot). I cut the tubes to length with standard tube cutter. I now have zero moisture problems even if I use the keezer as a fermentation chamber. I highly recommend this approach for moisture build up.

I am planning on doing a write up on the keg / carboy / line cleaner after I change a few things to make it even better. It performs beautifully but I want to be able to disconnect the vertical pipe to make storage, cleaning, and flushing easier.

See attached excel docs for parts list and pricing. A big thanks goes to homebrewtalk for all the quality posts that made researching my options much easier.

Cheers,

Ben