Rosshedley

Active Member

Hi brewers

My beers are super super foamy upon opening. I will lose *at least* half the bottle. I am surprised they have not exploded.

There seem to be three possibilities:

1). Infection. I don’t think this has happened as the beer tasted fine.

2). Bottled too soon. There is a possibility I bottled too soon so fermentation has continued to produce carbon dioxide.

3). Over primed. I added two sugar drops to each 500ml bottle, as instructed.

I have tried keeping in fridge for 1-2 days, which worked for one beer. But now I have had beers in fridge for a couple of weeks (plus 2 weeks bottle conditioning in cupboard prior to that) and they are still unopenably foamy. Have tried releasing cap slowly a few times over last couple of days to let pressure out but shows little sign of making a difference.

Any other recommendations?

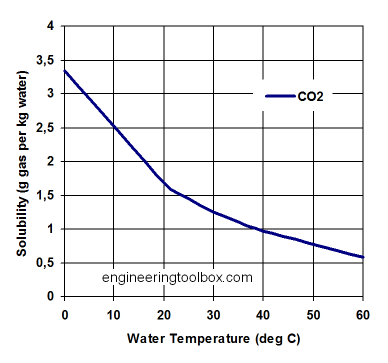

Also, I was curious if the ‘put in fridge for a day or two’ method resulted in the necessary science taking place such that the bottles could then be returned to room temp and then opened - not that I would want to, but trying to understand if that fix is just because beer is cold, or if cooling does some science magic which results in less carbonated beer permanently (i.e. even if returned to room temp)?

Kind regards,

Ross

My beers are super super foamy upon opening. I will lose *at least* half the bottle. I am surprised they have not exploded.

There seem to be three possibilities:

1). Infection. I don’t think this has happened as the beer tasted fine.

2). Bottled too soon. There is a possibility I bottled too soon so fermentation has continued to produce carbon dioxide.

3). Over primed. I added two sugar drops to each 500ml bottle, as instructed.

I have tried keeping in fridge for 1-2 days, which worked for one beer. But now I have had beers in fridge for a couple of weeks (plus 2 weeks bottle conditioning in cupboard prior to that) and they are still unopenably foamy. Have tried releasing cap slowly a few times over last couple of days to let pressure out but shows little sign of making a difference.

Any other recommendations?

Also, I was curious if the ‘put in fridge for a day or two’ method resulted in the necessary science taking place such that the bottles could then be returned to room temp and then opened - not that I would want to, but trying to understand if that fix is just because beer is cold, or if cooling does some science magic which results in less carbonated beer permanently (i.e. even if returned to room temp)?

Kind regards,

Ross