I would agree that if you are buying a PID controller with manual control you would not need a knob as well, I don't think you would actually be changing the manual value that often for it to really matter - you'd probably find the sweet spot and just sit at that for 95% of the boil time.

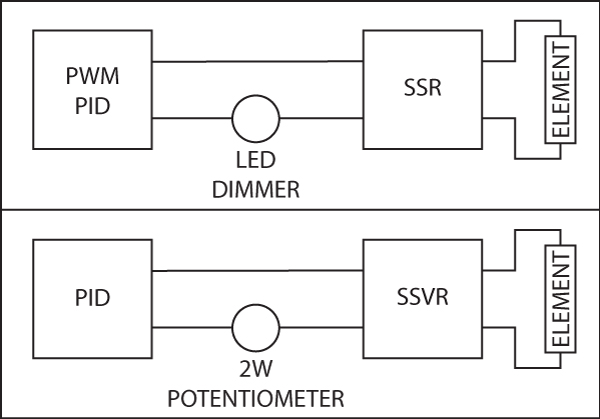

If you are determined, however, it have a knob to control it you do not need 2 SSRs or SSVRs. This is like using a sledge hammer to crack a nut. Whether you chose a PID controller that use PWM or a current output you can use either of the set ups shown below:

This will function exactly as the system already mentioned with 2 SSRs:

-For PID operation set the dimmer/potentiometer to 100% and use PID as normal.

-For "infinite control" set the PID into manual mode at 100% and control using the dimmer/potentiometer.

Personally, I would always opt for the PWM route.

The material by Dave Knott referenced is also correct, we do not need PID (proportional, integral, derivative) control in most cases. PID control is only required were there is a delay between the controlling actuation, such as a heating element, and the system's response. The likes of RIMS may need PID control since the temperature of the mash is of concern but there is a delay before the heated wort returns to the tun from the external heater. For a boil kettle or HLT, where the element is in the vessel, there is no significant delay and a thermostat style function is sufficient. However, if you autotune your PID to such conditions it should basically figure this out and do very little other than full power up until it is almost at the set temperature.

Never-the-less, we all use PIDs as, with advancements in micro-electronics, they are relatively cheap and very customisable - most accept many different kinds of temperature probes for example - and they are ready equipped with necessary outputs for relays, mechanical or solid state.