Brewsit

Well-Known Member

Im looking for any ingenious ways to dial in my fermentor temperature control. Here are the specs:

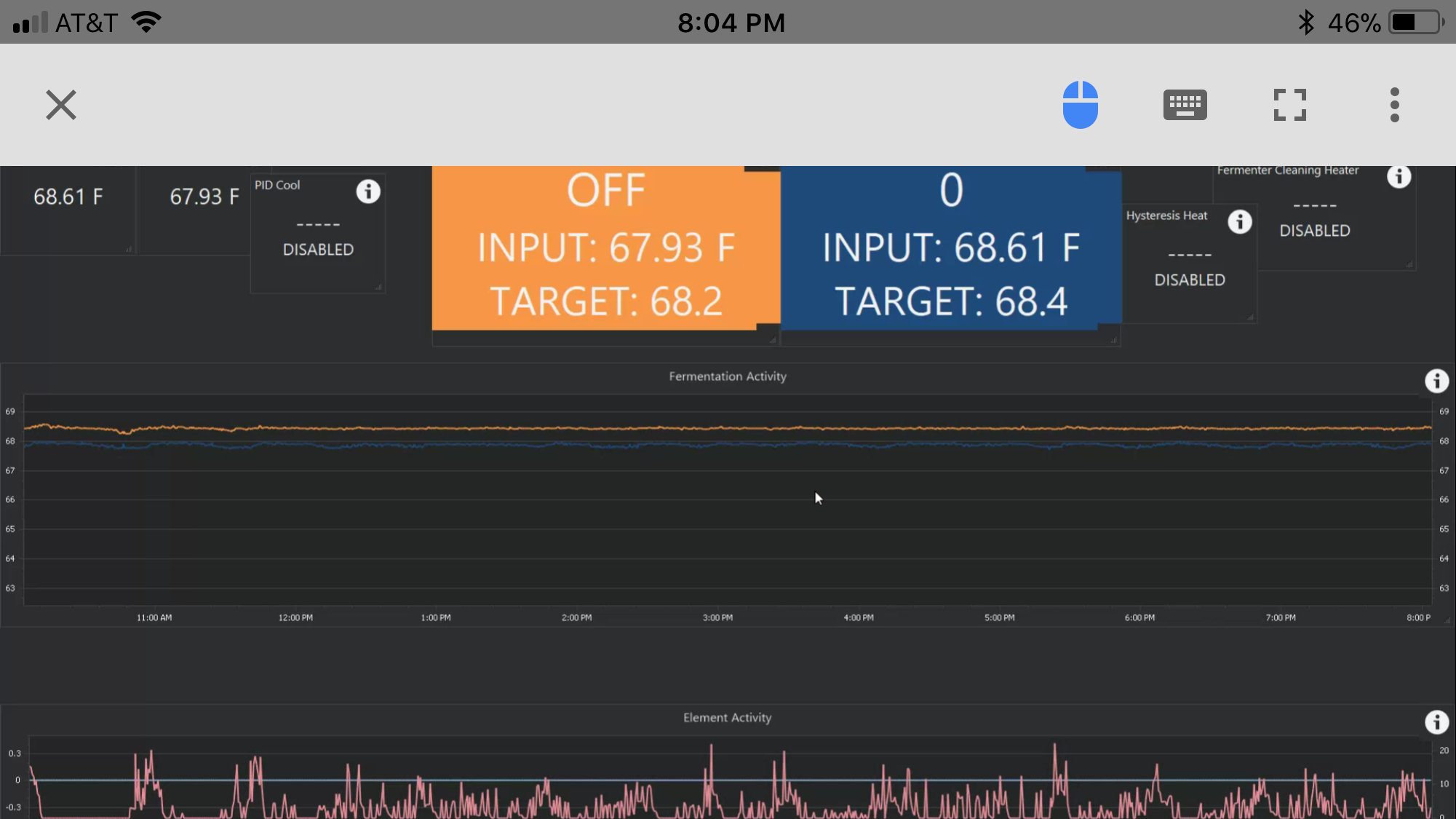

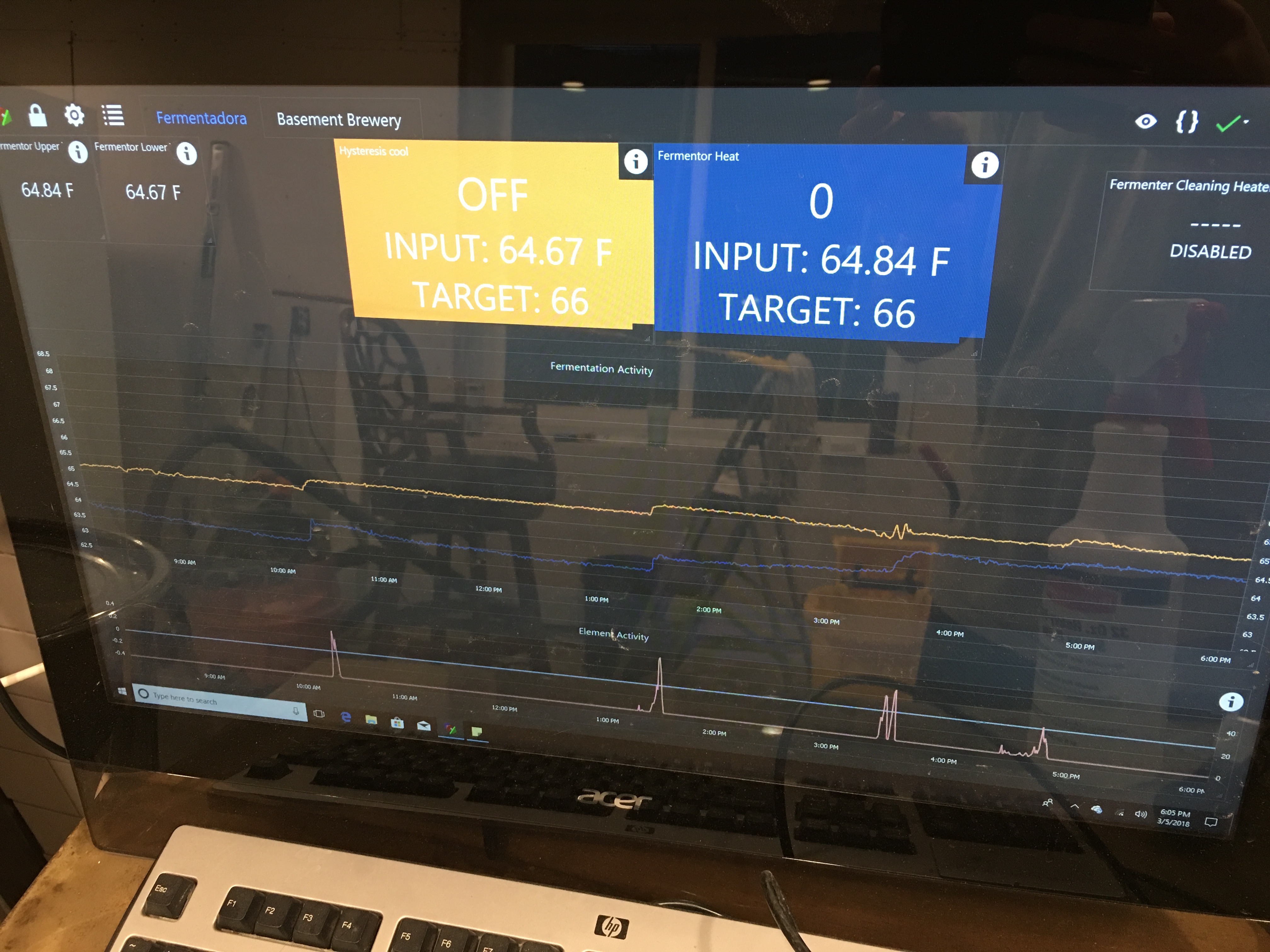

BruControl software

27 gallon Stout stainless conical

Two thermistor probes, one in the top a couple inches in the top of the wort, one near the bottom.

ULWD 4500w heating element for heat (hooked up as 110v)

55 gallon Glycol chiller with stainless immersion chiller in the fermentor

Chiller set up with hysteresis for the chiller, reading the lower temp probe. 2 min delay and 1 degree offset.

Heater set up with PID and upper temp probe, 18/0.5/0.5 as the initial tune.

The picture should give an idea of what I’m seeing. It’s a 10 hour x axis and 63-68 degree y axis.

The upper probe shows about 1/2 a degree warmer than the lower right now, and this has slowly gotten closer through the last 10 hours. The heater has run about 3 or 4 times, I have it set at 15% max output and 50% max integral. It has run a couple of times through the day, the ambient air temp is low 60s.

I honestly have a 3rd grader’s understanding of PID so I was trying to be conservative.

It seems pretty stable but the fermentation hasn’t really kicked off yet.

Any thoughts on how to optimize this setup?