mggray87

Well-Known Member

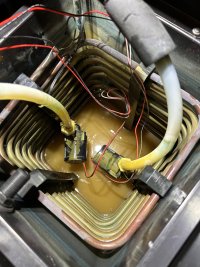

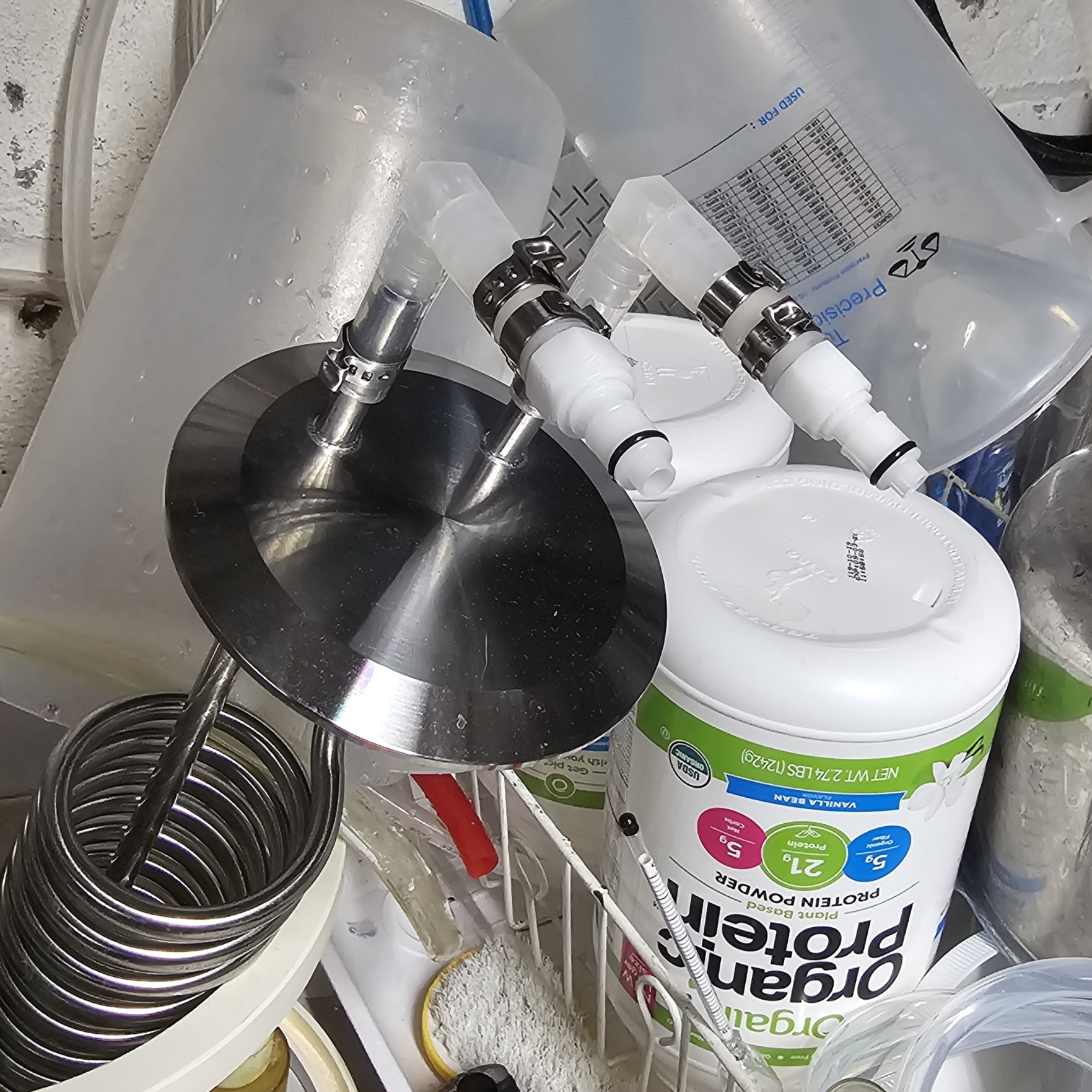

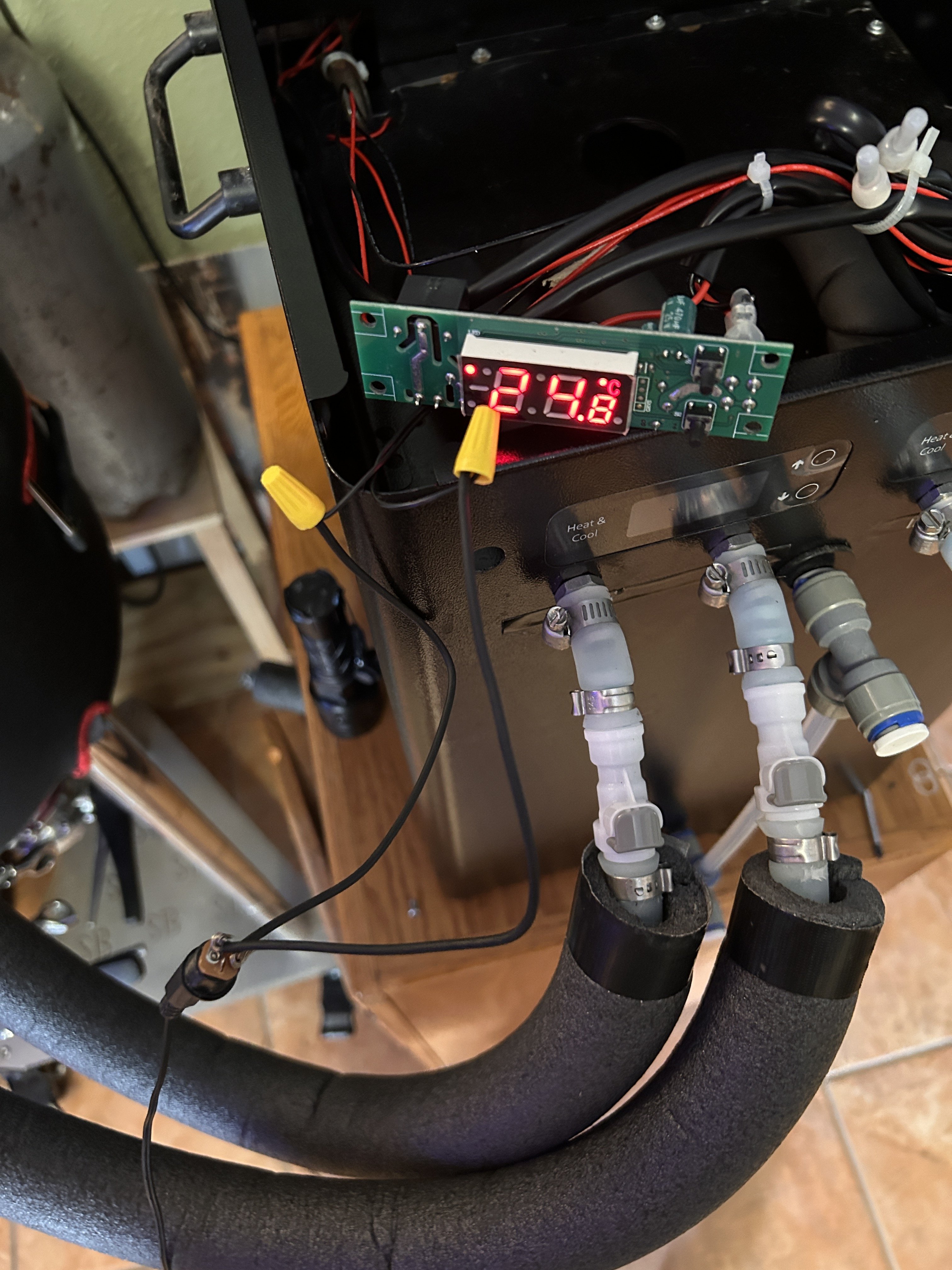

Ok so still tackling it. I have both of my 7g unitank 2.0s at 40f this morning. Which I had it set. Now slowly dropping it to 38 see if they both go. I had to do this slowly. Started at 50 then 45. Then 40 so it has a chance to get to temp and the glycol to get to a really cold temp. Otherwise it just runs runs. Also I calibrated the glycol temp when it was at say 4*c. It's accurate. But when I have it set to -2.0c it only got to 36. And compressor was off. So I assume the probe in there somewhere is on a coil or close to it. I'm testing in the center of the glycol. Last night I dropped the controller to -3c as mentioned. This morning the compressor was off but the glycol solution was 29*f. I just dropped it to -3.5*c and I'm I'm waiting for it to drop unitanks to 38* and then test the glycol temp to see where that puts the temp inside there.First calibrate the glycol bath probe as it seems to be a off by at least 1C but make sure you stir it really well to avoid testing a hot spot with your instant read. After that, try running the glycol tank at -3C for a while. Most find that the best cold crash they can get is done with 26F glycol. It's right on the edge of freezing the beer at the coil surface.

What cold crash temp should I aim for? 38*? Low enough or should I try to see if it can reach 36?

I'm guessing peak summer this will be impossible but if it does both at once. It should do one batch.. I'd think