Don't panic, you're actually almost there.

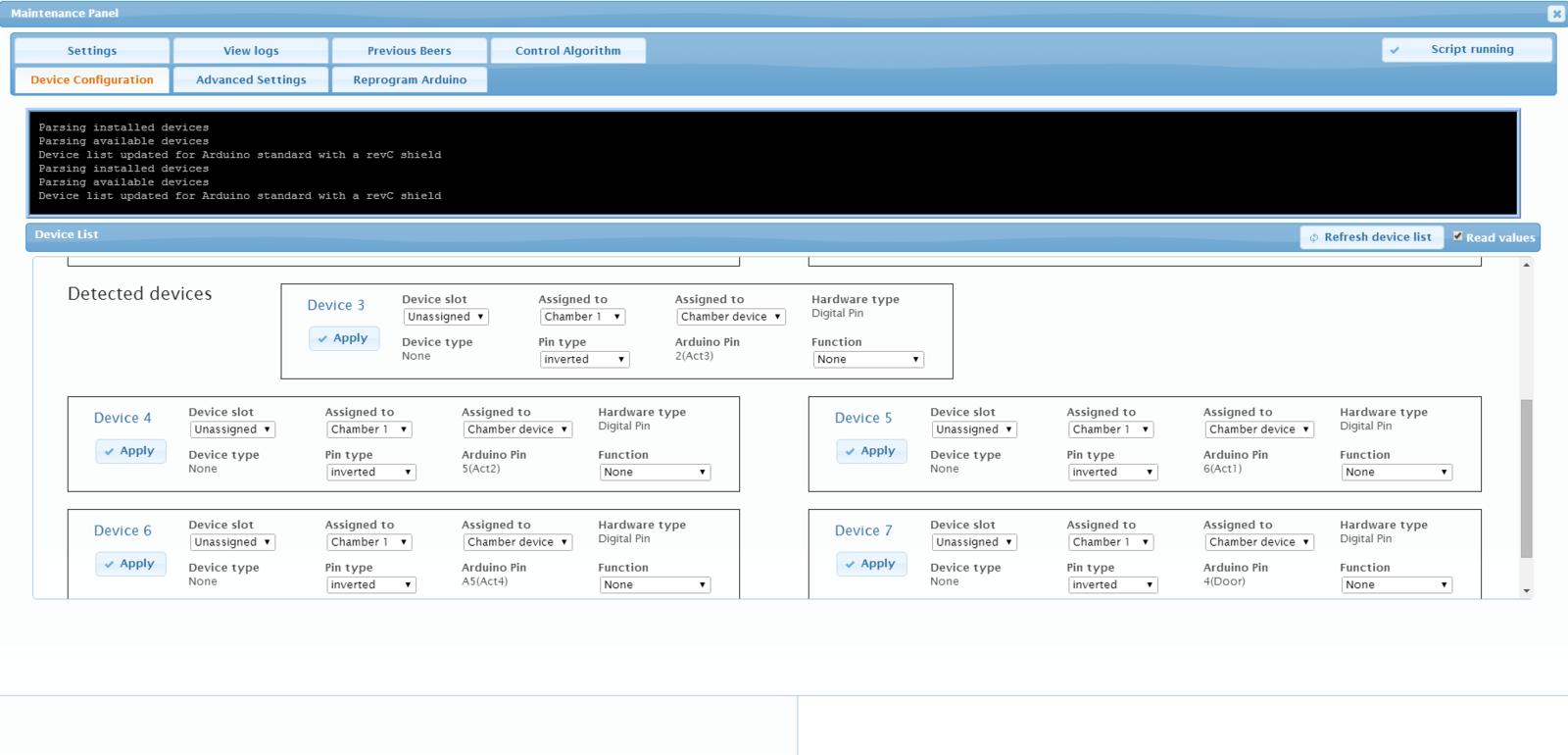

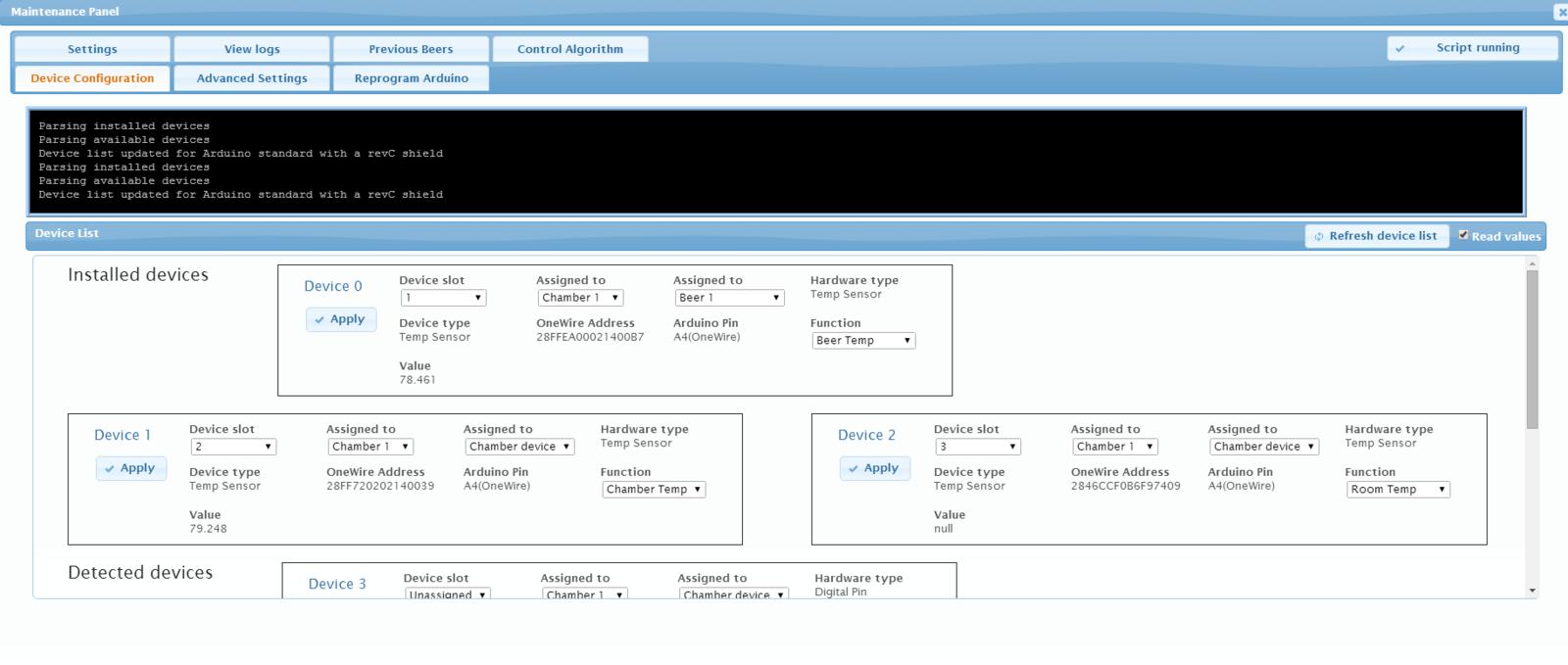

You're looking at Maintenance Panel - Device Configuration, and you see the Detected Devices. You can see two One-Wire devices, so BrewPi is seeing two temperature probes.

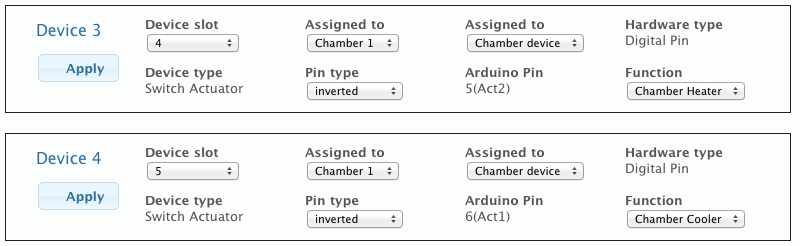

You just need to assign each real Detected Device to a Slot; for the probes, set the left "Assigned to" to the default Chamber (1); then if the probe is measuring the Beer temperature assign it to Beer 1, if it's for the air temperature inside the chamber assign it to Chamber device; then set the Function (Beer Temp vs Chamber Temp for probes).

Then hit Apply, click the Refresh Device list, then go to the next Detected Device, repeat...

Cheers!

You're looking at Maintenance Panel - Device Configuration, and you see the Detected Devices. You can see two One-Wire devices, so BrewPi is seeing two temperature probes.

You just need to assign each real Detected Device to a Slot; for the probes, set the left "Assigned to" to the default Chamber (1); then if the probe is measuring the Beer temperature assign it to Beer 1, if it's for the air temperature inside the chamber assign it to Chamber device; then set the Function (Beer Temp vs Chamber Temp for probes).

Then hit Apply, click the Refresh Device list, then go to the next Detected Device, repeat...

Cheers!