FuzzeWuzze

I Love DIY

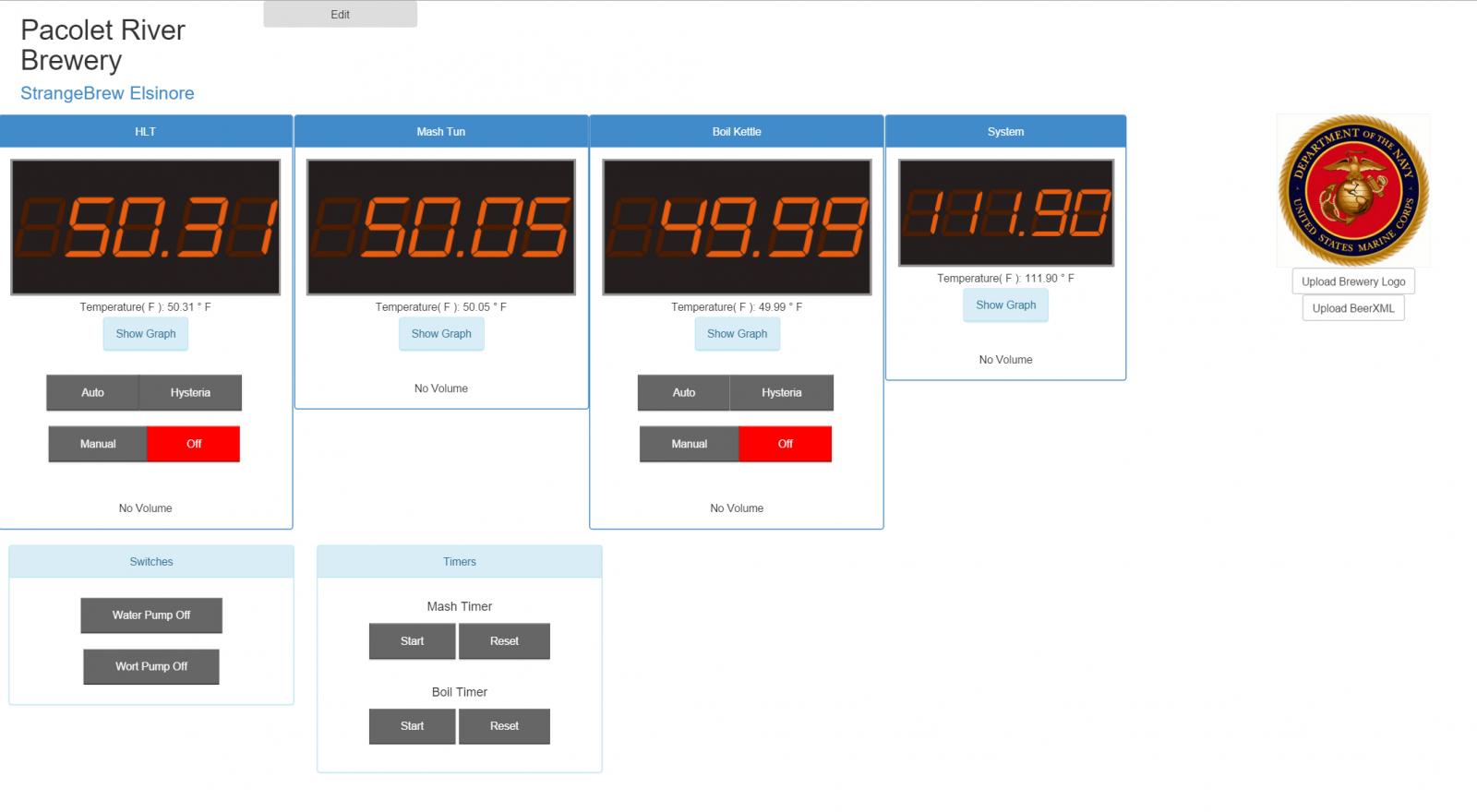

1 How do I know when updates are made to Elsinore?

2 Which version of Elsinore should I be using?

3 how can I help or report bugs?

4 I received my Hosehead about 3 weeks ago, would any of you know if the version of Elsinore that I have is up to date?

5 it specifically says on the Brewtronix site not to bother Doug about Hosehead issues, if I do have issues where can I address the problems?

I would like to thank Doug and Corey both for the work and knowledge they have put into these two projects that work together for the Home Brewing Community! Good work fellas! I understand that these projects are works in progress and in some cases there is no money being made. I wouldn't mind donating to the Elsinore project for the benefit of some great beer.

Use the https://www.reddit.com/r/strangebrew subreddit for all information pertaining to Strangebrew, updates, how to submit bugs, get help etc.

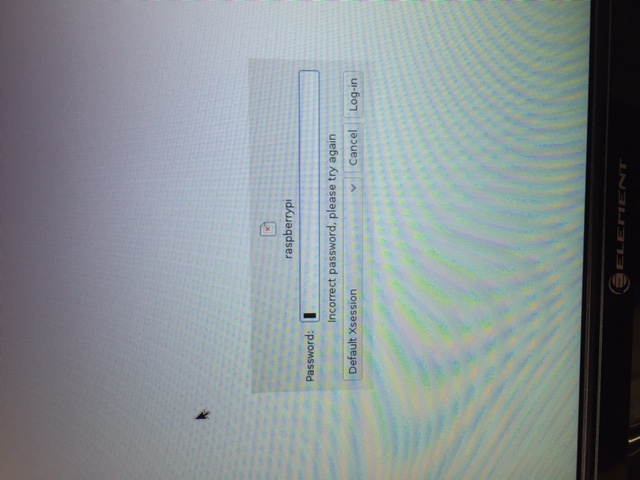

Log into your box with Hosehead RPI with Putty, go into the Strangebrew directory and type git pull, that should do it. I believe Hosehead also had a youtube video or some instructions somewhere with more specifics if that doesnt make sense to you.

I doubt the version you have is the latest build, I am not 100% sure that Doug actually merged all his beta changes into the main code.