Elfmaze

Well-Known Member

Part of my switch to electric brewing seems to be a push toward HERMS vs RIMS that I was using on my gas fired brewery.

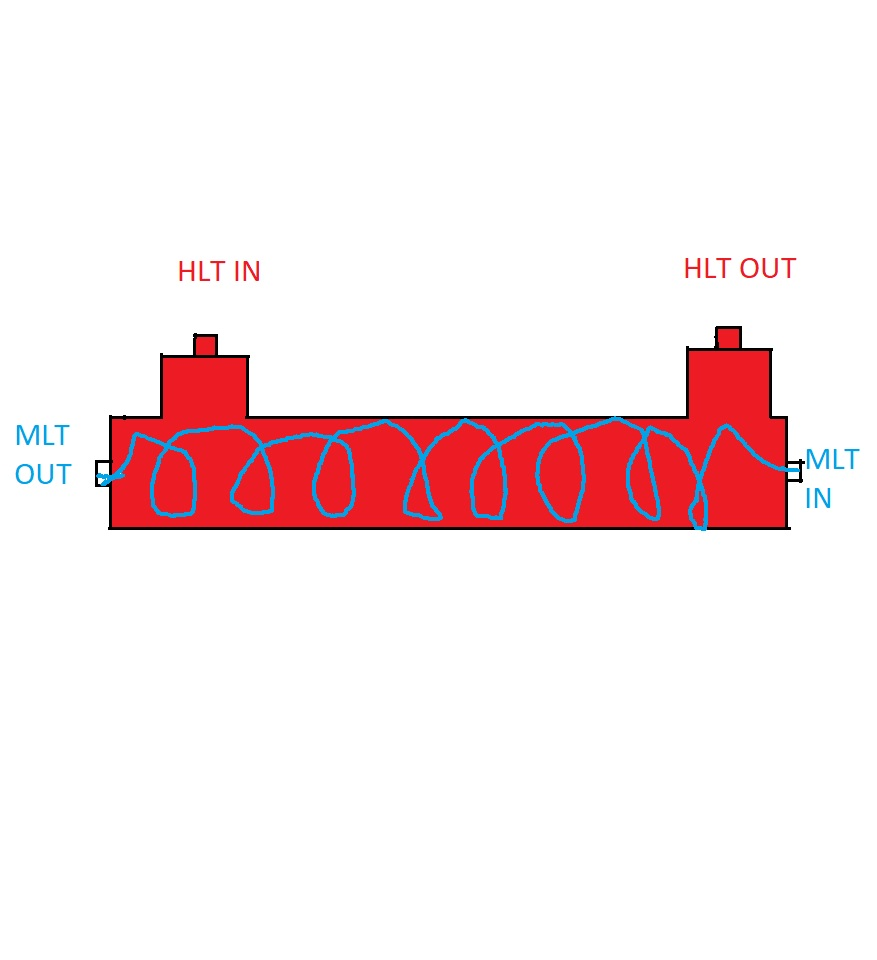

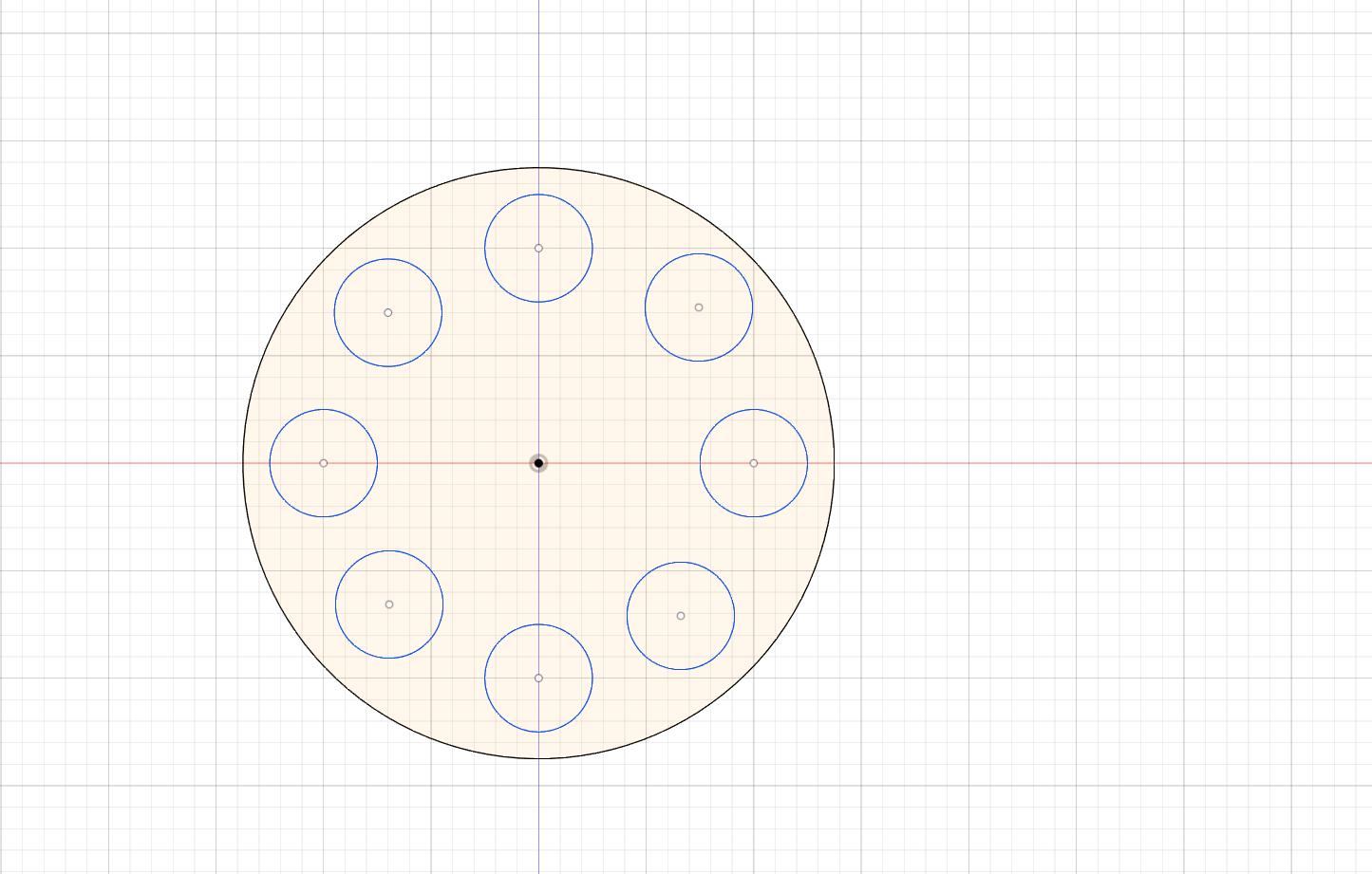

My HLT is a bit "cluttered" already and drilling and welding new holes in it is possible, but I have another idea. Since I am already recirculating the HLT. can I pass the HLT through this spare 3" x 36" triclamp tube I have and use two tees on either end with a 50ft coiled 1/2" SS tube to pass the Mash recirc through?

Biggest problem I see is more metal equals more heat loss to atmosphere and not sure how coiling 1/2 SS to 3" OD would work out. column would hold about one gallon of HLT water minus the volume of the SS tube.

My HLT is a bit "cluttered" already and drilling and welding new holes in it is possible, but I have another idea. Since I am already recirculating the HLT. can I pass the HLT through this spare 3" x 36" triclamp tube I have and use two tees on either end with a 50ft coiled 1/2" SS tube to pass the Mash recirc through?

Biggest problem I see is more metal equals more heat loss to atmosphere and not sure how coiling 1/2 SS to 3" OD would work out. column would hold about one gallon of HLT water minus the volume of the SS tube.