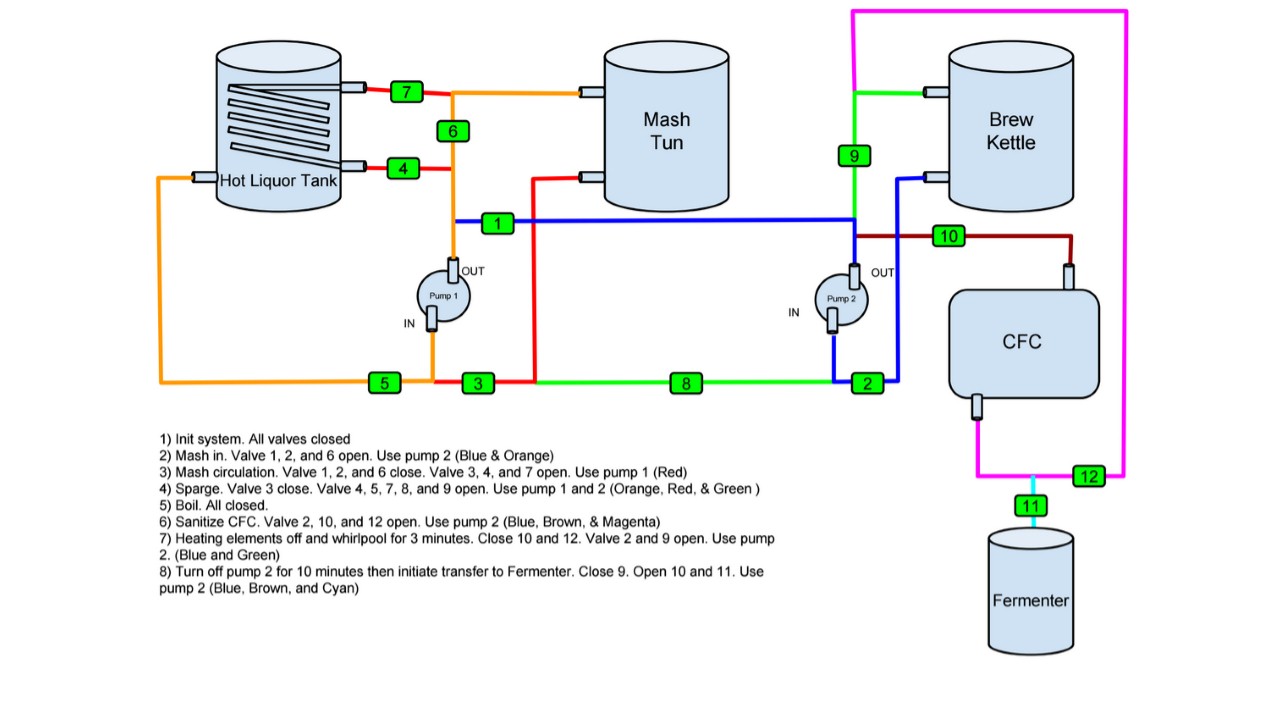

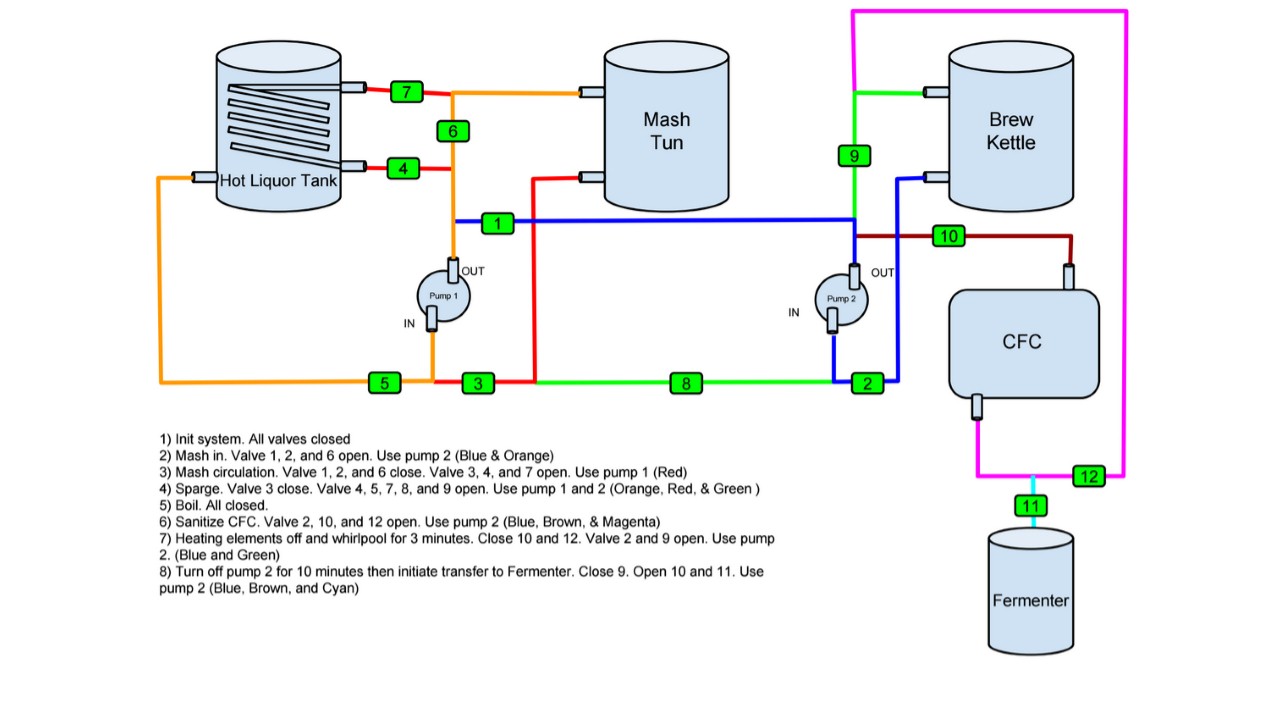

Below is a schematic I put together showing the plumbing and valves for my system. Not sure I'm going to go this route and I'm looking for input. This basically automates all of the fluid movement from heating the water to filling the fermenter. I've looked at this for hours upon hours trying to figure out a more efficient way to do this and to eliminate some of the mechanical ball valves (12 seems like an awful lot).

All comments and suggestions are welcome.

Thanks!!

All comments and suggestions are welcome.

Thanks!!