After a long (a little too long) hiatus from HBT to finish my entire basement I am back, and have caught the electric brew indoors bug. I've searched high and low and cannot find exactly what I am looking for so I figured I would put this out there.

Here are my goals:

-I will likely do 10-15 gallon batches, potentially back to back with the aid of a NG stove top 15 feet from the brew stand.

-50 Amp service to my (currently) unfinished brew room. It is only about a 15' run to my panel that already has a 50 A GFCI ready to go from the hot tub I'm about to get rid of.

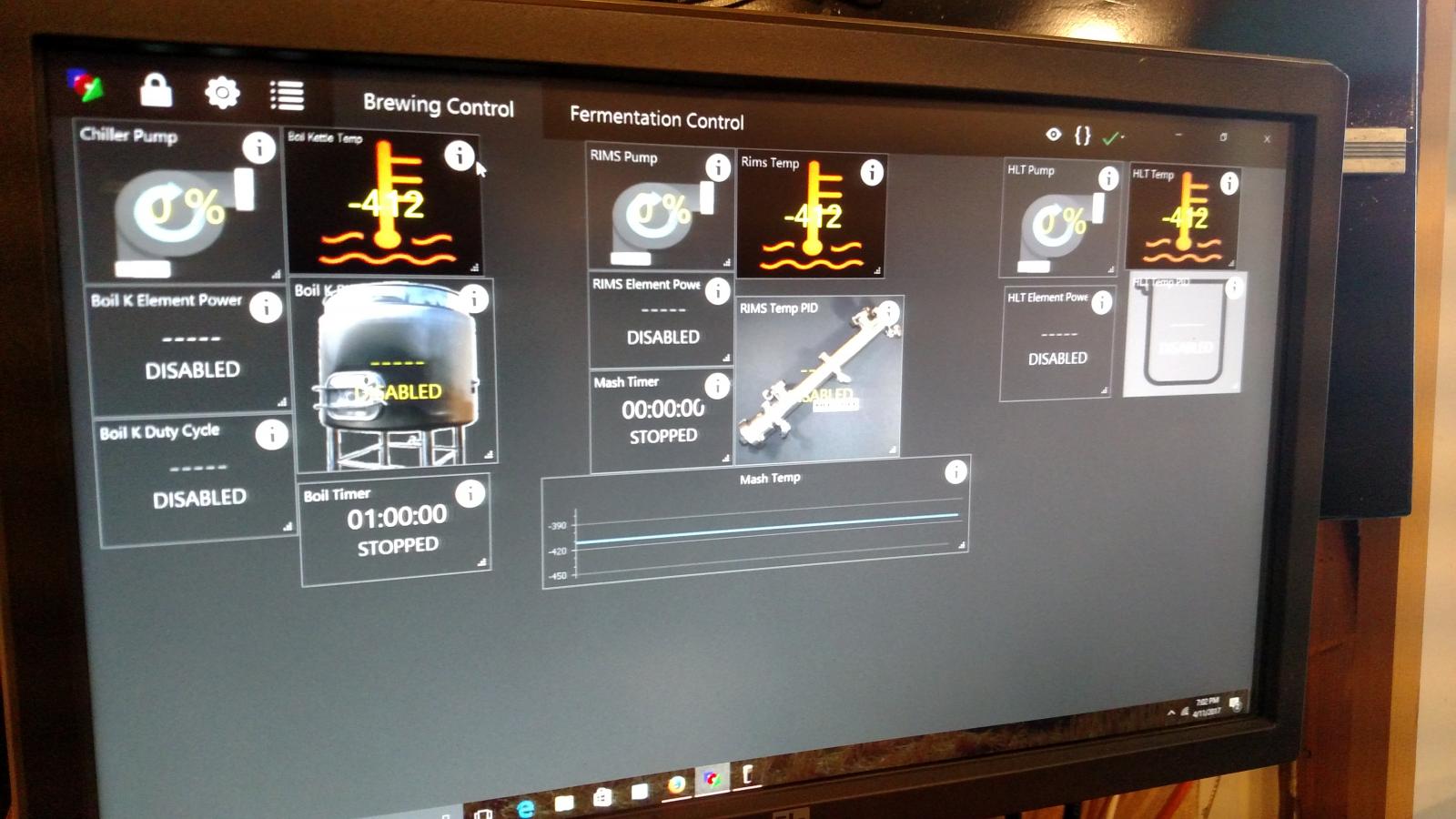

-I would like to run a 5500 W element in both the BK and the HLT, although not at the same time.

-I would like to be able to run a 5500 W element @ 120 V inside of the RIMS tube while the HLT or BK elements are firing. This would allow me to hit strike/boil temps faster.

I have not been able to locate any builds that have achieved this over the past couple days of searching.

I have decided upon RIMS because I want to have more responsive control over mash temps. Any advice you can give me is much appreciated.

Here are my goals:

-I will likely do 10-15 gallon batches, potentially back to back with the aid of a NG stove top 15 feet from the brew stand.

-50 Amp service to my (currently) unfinished brew room. It is only about a 15' run to my panel that already has a 50 A GFCI ready to go from the hot tub I'm about to get rid of.

-I would like to run a 5500 W element in both the BK and the HLT, although not at the same time.

-I would like to be able to run a 5500 W element @ 120 V inside of the RIMS tube while the HLT or BK elements are firing. This would allow me to hit strike/boil temps faster.

I have not been able to locate any builds that have achieved this over the past couple days of searching.

I have decided upon RIMS because I want to have more responsive control over mash temps. Any advice you can give me is much appreciated.

. I think I wrote it off because it was a 30 A setup. At this point I am definitely going with 50 A in an effort to future proof my setup. I'm gonna read through your thread again!

. I think I wrote it off because it was a 30 A setup. At this point I am definitely going with 50 A in an effort to future proof my setup. I'm gonna read through your thread again!