How many people brew with the GF in the kitchen ? How do you handle drips and spills ? How do you sparge ? What does your SO think of you brewing in the kitchen ?

Thanks

I do, and outdoors when weather is nice. Likely moving to basement brew area I'm working on (after I complete my kitchen island, new cabinets come in this week!). I don't make too much of a mess, but on hardwood floors its an easy wipe, and I do clean the floors at the end of most brew days. Manual sparge with a pitcher, heat water on stove top, it remains there throughout my sparge with lid on and heat either off or on low. SO, hates the smell, but we work out so I have the kitchen on brew days.

...OK issue at hand. I had my first brew day with the GF last night. Had a few issues. First, the sparging seemed to go REALLY fast. Like I could not keep up with the water level dropping. Normal?

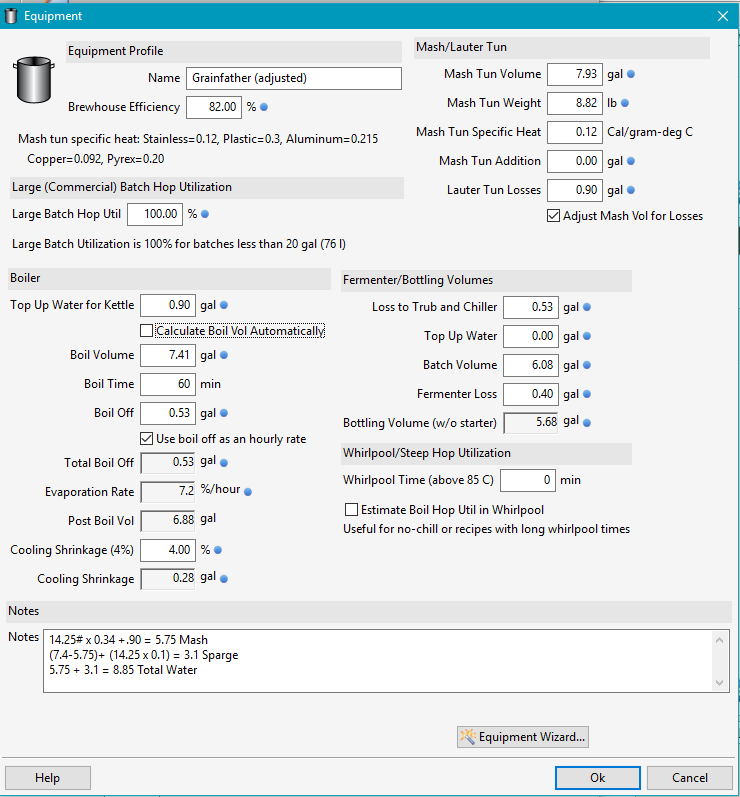

Next, I'm not sure if I had the equipment profile wrong, or it was just something else. My OG was WAYYYYYY off. 13 points off. But I am 90% sure it was due to boil off. I wanted a 5.25 gallon batch. I collected 5.7 Gallons of wort in my fermenter. The GF had like 2.5 gallons left in the kettle. The boil was pretty pathetic, so I'm not sure it actually hit the proper boil off level. The kettle was over the scale inside, so I'm not 100% sure how much was being boiled.

12 pounds of grain, asked for 5 gallons of water, and 3.75 gallons of sparge water.

No, not normal. First, did you push the top plate down after the 1st runnings completed? (it may fall down on its own, but IME the grain bed compacts about 4" after draining). If you didn't this open space may have led to your results.

As for your volume, I came up with same mash water but just ~3g of sparge. You do have to play around with your figures not just working on your boil off rate and boil length, but also amount of hops. I too used to overshoot my vol into fermenter, now I'm dialed in and I find ~1L left in GF (I tip towards pump) and 1/2c in CFC at best.

But what I really don't understand is if the GF had 2.5g left in boiler & you got 5.75g in fermenter, how was that with grain absorption of ~1.5g+?? Something isn't adding up here...

Looking at grain absorption, .13gal per lb, you would lose 1.56 gallon to 12 lbs of grain via absorption. If you wanted 5.25 gallons into the fermenter, with trub losses of 1 gal, and boil off of .6 per hour, I see 5.25 + 1 + .6 + 1.56 = or 8.41 total volume of water.

With a mash thickness of 1.33 quarts/lb, that's 15.96 quarts or 3.96 gallons, + .9 in deadspace below mash pipe. That's 4.89 gallons of strike water, and 8.41-4.89 = 3.52 gallons of sparge or so? Not far off I don't think. Of course my calculations could be a bit off so there's always that.

Maybe a combination of lack of boil off with maybe too large of a crush or something that the grain didn't absorb as much? What were the pre/post boil volumes?

I think your trub loss is too high, unless you use a LOT of hops, which indeed will change the calcs. I'm still ~.4g< than your calc.