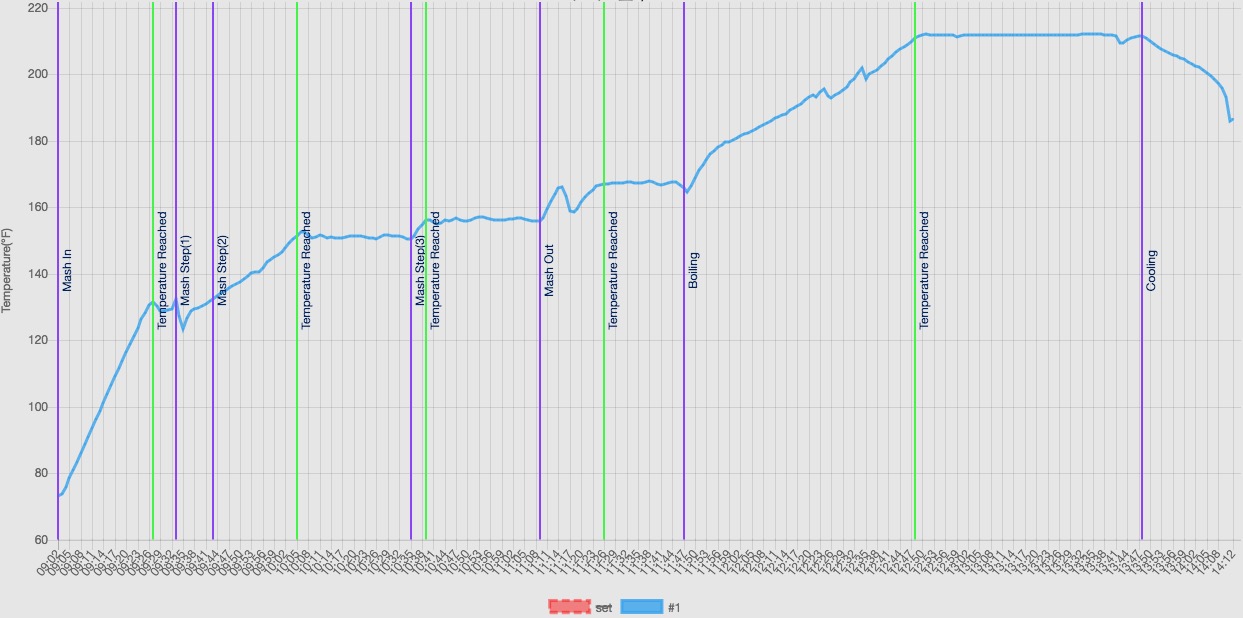

what's the max grain bill folks have used? I just made a rye porter that was just shy of 17lb and noticed that when mashing, it was almost topped off. i noticed that while mashing and recirculating, a lot of wort was flowing through the side holes where the lifting handle fits in. is this normal for larger grain bills? I mashed w/ 6.75 gal water. i was wanting to do a large barley wine soon but worried about fitting anything more than 17lb of grains.

I haven't gone that high yet, only to 15#. Interesting point that it was circulating through those side holes, how high then was that on the overflow tube? Maybe throw in some rice hulls in larger batches to improve water flow. I do throttle mine back to avoid the overflow, and generally I can open up wider as the mash progresses. Did you adjust?