- Joined

- Jan 4, 2015

- Messages

- 100

- Reaction score

- 53

I posted in DIY but I wanted to ensure others knew about the build and/or first-timers with fermentation chambers. Shoot me some suggestions for lagers I should try with this bad boy!

I surf this forum religiously when embarking on a new adventure or project. Thanks to everyone who contributes and I hope to help others with this post. I wanted to share my latest build for a DIY fermentation chamber and learning how to dial in the temperature, having healthy and happy yeast. I have been on and off brewing beer for about 5-6 years now and have been using a swamp cooler to try and control temperatures. This works for the most part, but constant monitoring and inability to brew lagers drew my interest in dialing in my fermentation game. Due to my small home, I decided to build a DIY mini-fridge fermentation chamber that would hold one 6.5 gallon glass carboy with airlock. I decided to purchase a mini-fridge brand new rather than dealing with Craigslist and hoping to find something that would fit my specifications.

Some other considerations made were:

- Not having to cut, scrape, and bend components inside the fridge. Minimum destruction as possible.

- I want the ability to ferment at ale and lager temps, as well as cold-crash.

- Try to set up something fairly simple.

Fridge and Collar

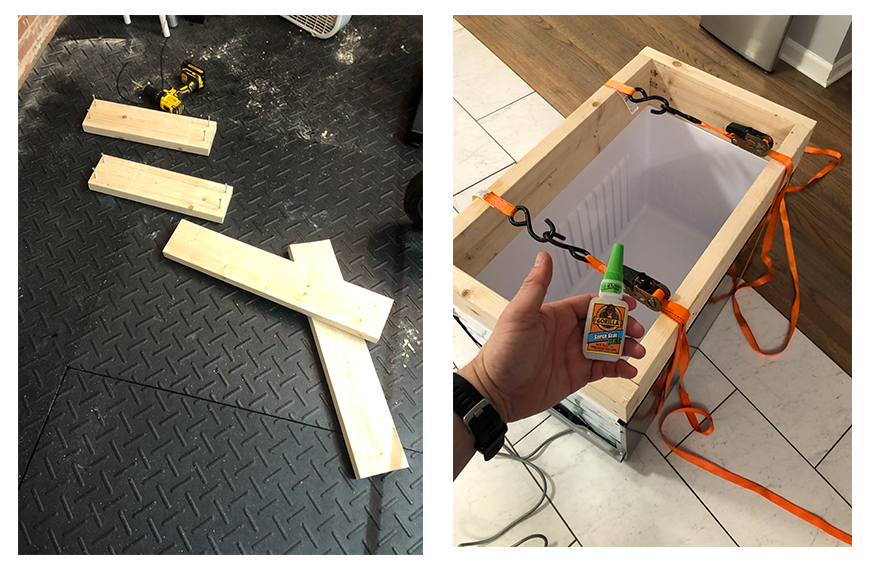

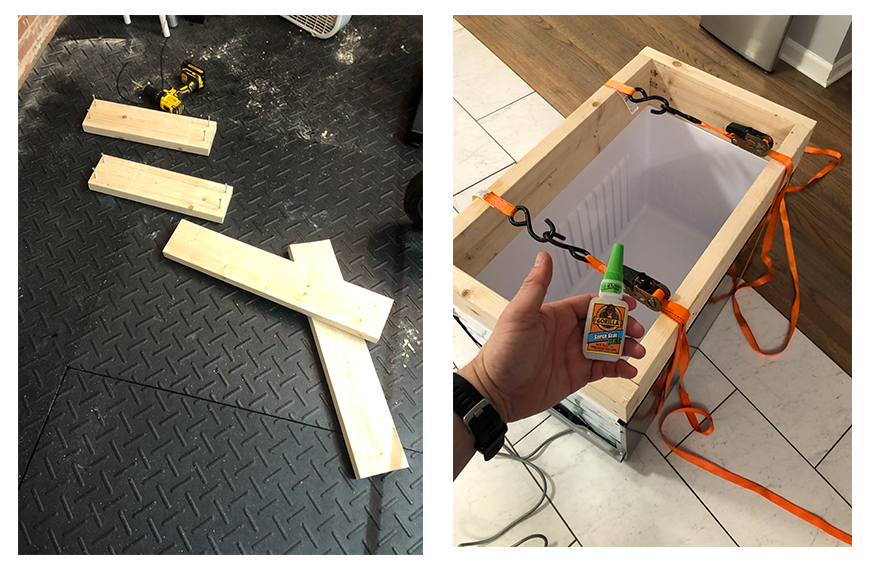

I bought the Frigidaire 4.4-cu ft Mini Fridge from Lowes for $179.99. The door came off with no problem, just a few screws. I knew I would need a collar, so I used a 2x6 to place around the fridge. Then I used some Gorilla Glue to glue the collar on the fridge with some ratchet straps to apply pressure until the glue was dried. Liquid Nails would have probably worked better because it doesn't set near as fast, but does take more time to dry. I then used some DAP Kwik Seal caulk for a nice seal around the inside space of the fridge and collar. No extra insulation was added and with a preliminary test, temperatures held just fine. I am able to get the fridge down to 34F/1C no problem. I also used some linseed oil and wood finisher to seal the wood so things like beer/water wouldn't funk up the wood collar over time.

Temperature Controlling Components

As far as the components that help regulate temperature, I used the following:

- Simple fan to circulate the air. This fan runs all the time.

- Low wattage heater to provide heat.

- BTC201 Temperature control unit. Plug both the heater and fridge into this unit, which then is plugged into the wall.

To mount the fan, I drilled from the inside of the fridge with a 1/8 drill bit through the plastic, enough to get the mounting screws for the fan to have a tight fit. It mounts nicely like this. Then used a 1-inch wood drill bit to drill out a hole where the wires will run (the heater and fan wire out, and the temperature probe line in). These really came in handy for cable management too. Mounted the BTC201 directly to the fridge on top.

Final Touches

The door does not stay shut unless you use some sort of latch or some way to use the magnetic structure built into the door. I decided to use 3 rare earth magnets burrowed into the collar. This helped keep the door sealed to the collar.

Here are some YouTube videos where some of the inspiration for this build.

- Link 1

- Link 2

- Link 3

- Link 4

I surf this forum religiously when embarking on a new adventure or project. Thanks to everyone who contributes and I hope to help others with this post. I wanted to share my latest build for a DIY fermentation chamber and learning how to dial in the temperature, having healthy and happy yeast. I have been on and off brewing beer for about 5-6 years now and have been using a swamp cooler to try and control temperatures. This works for the most part, but constant monitoring and inability to brew lagers drew my interest in dialing in my fermentation game. Due to my small home, I decided to build a DIY mini-fridge fermentation chamber that would hold one 6.5 gallon glass carboy with airlock. I decided to purchase a mini-fridge brand new rather than dealing with Craigslist and hoping to find something that would fit my specifications.

Some other considerations made were:

- Not having to cut, scrape, and bend components inside the fridge. Minimum destruction as possible.

- I want the ability to ferment at ale and lager temps, as well as cold-crash.

- Try to set up something fairly simple.

Fridge and Collar

I bought the Frigidaire 4.4-cu ft Mini Fridge from Lowes for $179.99. The door came off with no problem, just a few screws. I knew I would need a collar, so I used a 2x6 to place around the fridge. Then I used some Gorilla Glue to glue the collar on the fridge with some ratchet straps to apply pressure until the glue was dried. Liquid Nails would have probably worked better because it doesn't set near as fast, but does take more time to dry. I then used some DAP Kwik Seal caulk for a nice seal around the inside space of the fridge and collar. No extra insulation was added and with a preliminary test, temperatures held just fine. I am able to get the fridge down to 34F/1C no problem. I also used some linseed oil and wood finisher to seal the wood so things like beer/water wouldn't funk up the wood collar over time.

Temperature Controlling Components

As far as the components that help regulate temperature, I used the following:

- Simple fan to circulate the air. This fan runs all the time.

- Low wattage heater to provide heat.

- BTC201 Temperature control unit. Plug both the heater and fridge into this unit, which then is plugged into the wall.

To mount the fan, I drilled from the inside of the fridge with a 1/8 drill bit through the plastic, enough to get the mounting screws for the fan to have a tight fit. It mounts nicely like this. Then used a 1-inch wood drill bit to drill out a hole where the wires will run (the heater and fan wire out, and the temperature probe line in). These really came in handy for cable management too. Mounted the BTC201 directly to the fridge on top.

Final Touches

The door does not stay shut unless you use some sort of latch or some way to use the magnetic structure built into the door. I decided to use 3 rare earth magnets burrowed into the collar. This helped keep the door sealed to the collar.

Here are some YouTube videos where some of the inspiration for this build.

- Link 1

- Link 2

- Link 3

- Link 4

Last edited: