r8rphan

Well-Known Member

It's been about two and a half years since I brewed, but I want to upgrade my system and start again..

I've always hated the inconsistency of using a cooler for a mash tun, and the hassle of cleaning it out and all... I'm also getting kind of old and have some spine issues, so I want to avoid the heavy lifting as much as possible..

Anyways, I want to go to an all electric, single kettle BIAB system.. and save the propane set up for the event of a SHTF/societal collapse/zombie apocalypse.. I can use it to make bottle bombs.. lol

Anyways, I have an extra sanke keg that I want to use as my kettle if possible to avoid buying one..

So my plan is to use the tapper connection as a drain/outlet on the bottom.. I plan to turn the keg upside down, use a tri clover fitting to attach the plumbing and then cut the entire bottom off of the keg (now the top) just below where the handle ring is welded, using an angle grinder.. I will have probably 5-6" underneath the basket for a heating element and false bottom (full immersion of basket), so I hope that is enough....

This will allow me enough room to use the turkey fryer basket that came with my turkey fryer (that I bought for brewing way back in the beginning many years ago), and a mesh bag to hold the grains (should hold about 30 lbs or so)

My plan is to build a metal frame structure with a little I beam or unistrut track/trolley on it so I can just pull a block and tackle mounted on the trolley to lift the grains, trolley to next to the kettle, grab the mesh bag and go dump them in the compost bin.. easy peasy...

So, I need to buy a chugger pump ($150), and a PID/SS Relay/heat sink/Temp Probe kit ($40) from amazon, and heater element... I am also tired of dealing with heavy glass carboys.. So I want to buy one of the cheap plastic 15G conicals I see on various Ag or plastic suppliers ($60 plus shipping) and pump directly from the brew kettle (after chilling) into the fermenter which will be on a stand inside my fermentation chamber... I also will need a heater element, but I'm not sure what size is sufficient (I was thinking 5500kw?)

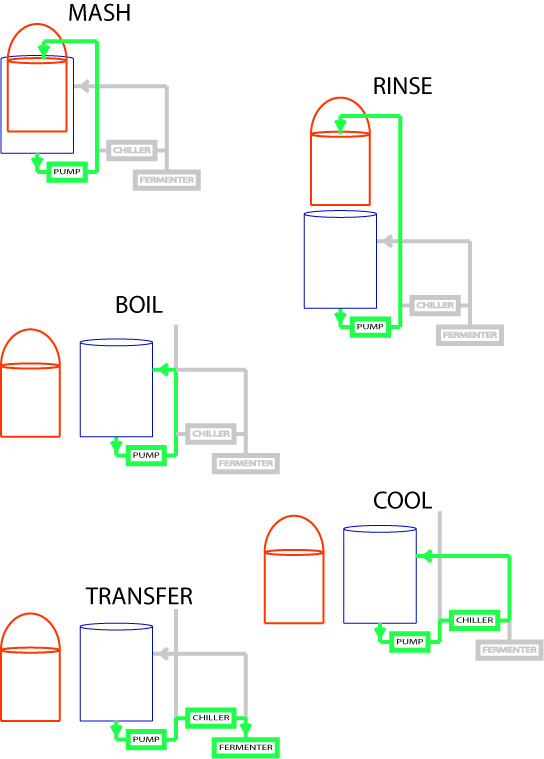

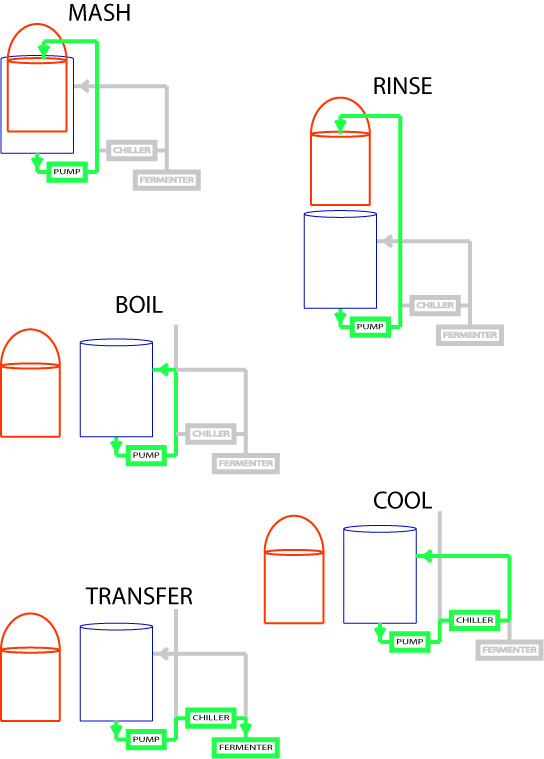

Before I get into my other questions, I wanted to post a flow chart/diagram of brew day and run it past you guys, so that I would not make any 'big' mistakes at the concept level...

After that is nailed down, I'll get into some of my other questions regarding logistical problems I need to solve and nitty gritty of equipment, fittings, parts, etc......

So here is the flow chart... Tell me if you see any problems...

I've always hated the inconsistency of using a cooler for a mash tun, and the hassle of cleaning it out and all... I'm also getting kind of old and have some spine issues, so I want to avoid the heavy lifting as much as possible..

Anyways, I want to go to an all electric, single kettle BIAB system.. and save the propane set up for the event of a SHTF/societal collapse/zombie apocalypse.. I can use it to make bottle bombs.. lol

Anyways, I have an extra sanke keg that I want to use as my kettle if possible to avoid buying one..

So my plan is to use the tapper connection as a drain/outlet on the bottom.. I plan to turn the keg upside down, use a tri clover fitting to attach the plumbing and then cut the entire bottom off of the keg (now the top) just below where the handle ring is welded, using an angle grinder.. I will have probably 5-6" underneath the basket for a heating element and false bottom (full immersion of basket), so I hope that is enough....

This will allow me enough room to use the turkey fryer basket that came with my turkey fryer (that I bought for brewing way back in the beginning many years ago), and a mesh bag to hold the grains (should hold about 30 lbs or so)

My plan is to build a metal frame structure with a little I beam or unistrut track/trolley on it so I can just pull a block and tackle mounted on the trolley to lift the grains, trolley to next to the kettle, grab the mesh bag and go dump them in the compost bin.. easy peasy...

So, I need to buy a chugger pump ($150), and a PID/SS Relay/heat sink/Temp Probe kit ($40) from amazon, and heater element... I am also tired of dealing with heavy glass carboys.. So I want to buy one of the cheap plastic 15G conicals I see on various Ag or plastic suppliers ($60 plus shipping) and pump directly from the brew kettle (after chilling) into the fermenter which will be on a stand inside my fermentation chamber... I also will need a heater element, but I'm not sure what size is sufficient (I was thinking 5500kw?)

Before I get into my other questions, I wanted to post a flow chart/diagram of brew day and run it past you guys, so that I would not make any 'big' mistakes at the concept level...

After that is nailed down, I'll get into some of my other questions regarding logistical problems I need to solve and nitty gritty of equipment, fittings, parts, etc......

So here is the flow chart... Tell me if you see any problems...