Not trying save electrical costs--trying to make sure the chiller lasts. Again, its only running about 3 hours a day (so far). Maybe a bit more today as fermentation ramped up, but I don't think so.

I was just joking because earlier you said energy costs weren't important, and they really aren't much no matter what one uses for chilling.

And it is not cycling often. My bet is it is designed to handle frequent cycling anyway--it's an aquarium chiller... from my experience with reef fish tanks and hot metal halides hanging above them (to grow coral) that's what these chillers do--cycle frequently! To maintain a precise temperature (a sudden drop of even just 2-3 degrees can bleach or kill stony coral).

There no easy way to make an AC compressor handle frequent cycling, so I doubt it has anything to mitigate cycling. Running for longer times, with fewer cycles, is what they like. I don't know how factual it is, but I have read that a fridge is the longest lasting of all household appliances. They can last a very long time as long as they aren't short cycled, or cycled too frequently. The general consensus is that total run time is a much smaller contributor to failure than cycle count is.

The temp differential setting is what has to biggest impact on cycling freq. That would be one downside to not using the bath, as I commented earlier. To maintain ~1F variance with no buffer may cause excessive cycling. This is what the bath provides, as does the air when using a fridge and controlling to actual beer temps.

there is no reason for the bath

1. How would I control two different fermenters independently.

Convince another relative give up their reef tank hobby!

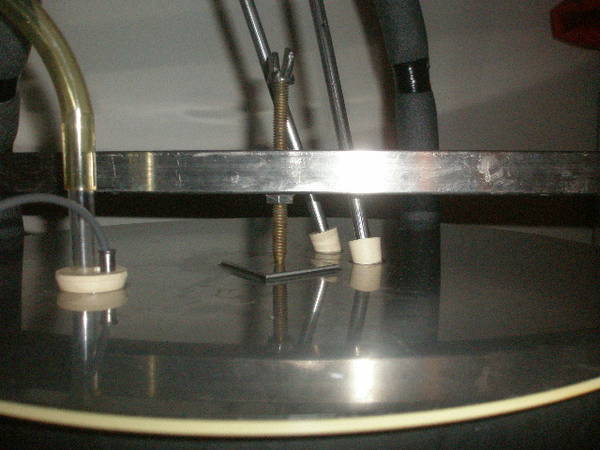

Seriously- A solenoid valve for each fermenter tied to the temp controller. Almost what you are doing now, I assume, just with 2 pumps, instead of 2 solenoids and one pump. You do lose your reserve capacity and cycle smoothing of the buffer/battery that the bath provides.

2. The chiller came from a fish tank.... My beer is not going through it...

I was referring to hooking the chiller up directly to the chiller, with the pump inline of course. I wasn't referring to cycling you beer through the chiller, although it does appear to have titanium piping. Serious bragging rights if you did do it. Stainless, please. Haven't you heard- titanium is the new SS. I don't even like CF chillers, so not for me though.

1/10 hp = ~100W

The chiller runs at 2.6 amps and is 115 volt... I think your calculation is off.

I already answered this one.

This weekend there will be 22 gallons going... Again--the chiller isn't struggling with 12 gallons. It's barely running. Maybe 4 hours a day and that being generous.

That is about 20% run time which is close to freezer run times also. A freezers performance does degrade when heat extraction demands increase due to the colder temps needed to compensate for the lower conductivity/transfer rates from using air. The aq chiller should have a much more linear increase as demand increases since the evap temps stay relatively constant, not going to -10F like a freezer.

That 80 cents per 10 days in Jacksonville.

You guys are at ~$0.08/kWh? Cheap. I think I am ~$.014.

If the chiller jumps to running 12 hours a day (3X more) that will be $2.28 per 10 days in Jacksonville.

It may be even less. The 2.8 is probably peak/start current. Chilling is cheap.

In contrast, once again, nothing is wrong with chest freezers. However, if they have 20-30 gallons of fermenting beer--they run near or totally constantly.

however, you have failed to convince me (or likely anyone) that the chest freezer is more efficient to use for that volume of beer.

I was talking, and still am, about the size of chiller needed to do that. If a freezer with a 4 amp motor can't keep up, even given its issues at high loads, it is doubtful that an aq chiller at ~1/4 the energy input, even with its advantages, could keep up either, and the coil to beer bit is not relevant here. This assumes both can keep up. It would need to have a COP 4X the freezer. It could be possible, but it is not a clear cut case that doesn't need some experimental verification.

That said, the my secondary fermentation will be in chest freezers. It has nothing do with efficiency. My secondaries/serving vessels are corny kegs and I can fit butt load of them in the chest freezers. The chest freezers do not run all the time to maintain non-fermenting beer at any temperature. Chest freezers, IMO, for that purpose, are ideal.

This is why your lager issue confuses me. Ferming a lager at ~50F should be so low power to be almost equivalent to maintaining finished beer at 50F. If you put them in there hot, and tried to ramp to 50F, I could see issues with a runaway ferm the freezer would have trouble with dropping.

Chest freezers also work well for primary fermenting--the compressor just runs more than this chiller set up and the temperature control does not respond as quickly.

It is different than my experience, but I also don't have a 1.8A plate rating. Fans help a lot with transfer rates, and why fridges 'as built' are probably a better choice for high volumes. For crashing, the aq chiller, especially with the bath/battery is for sure better down to some beer-chill fluid temp diff. Going past that temp, or as the glycol system nears the temp, the fridge based setup will start to outperform it due to its -10F temp floor.

I was just joking because earlier you said energy costs weren't important, and they really aren't much no matter what one uses for chilling.

And it is not cycling often. My bet is it is designed to handle frequent cycling anyway--it's an aquarium chiller... from my experience with reef fish tanks and hot metal halides hanging above them (to grow coral) that's what these chillers do--cycle frequently! To maintain a precise temperature (a sudden drop of even just 2-3 degrees can bleach or kill stony coral).

There no easy way to make an AC compressor handle frequent cycling, so I doubt it has anything to mitigate cycling. Running for longer times, with fewer cycles, is what they like. I don't know how factual it is, but I have read that a fridge is the longest lasting of all household appliances. They can last a very long time as long as they aren't short cycled, or cycled too frequently. The general consensus is that total run time is a much smaller contributor to failure than cycle count is.

The temp differential setting is what has to biggest impact on cycling freq. That would be one downside to not using the bath, as I commented earlier. To maintain ~1F variance with no buffer may cause excessive cycling. This is what the bath provides, as does the air when using a fridge and controlling to actual beer temps.

there is no reason for the bath

1. How would I control two different fermenters independently.

Convince another relative give up their reef tank hobby!

Seriously- A solenoid valve for each fermenter tied to the temp controller. Almost what you are doing now, I assume, just with 2 pumps, instead of 2 solenoids and one pump. You do lose your reserve capacity and cycle smoothing of the buffer/battery that the bath provides.

2. The chiller came from a fish tank.... My beer is not going through it...

I was referring to hooking the chiller up directly to the chiller, with the pump inline of course. I wasn't referring to cycling you beer through the chiller, although it does appear to have titanium piping. Serious bragging rights if you did do it. Stainless, please. Haven't you heard- titanium is the new SS. I don't even like CF chillers, so not for me though.

1/10 hp = ~100W

The chiller runs at 2.6 amps and is 115 volt... I think your calculation is off.

I already answered this one.

This weekend there will be 22 gallons going... Again--the chiller isn't struggling with 12 gallons. It's barely running. Maybe 4 hours a day and that being generous.

That is about 20% run time which is close to freezer run times also. A freezers performance does degrade when heat extraction demands increase due to the colder temps needed to compensate for the lower conductivity/transfer rates from using air. The aq chiller should have a much more linear increase as demand increases since the evap temps stay relatively constant, not going to -10F like a freezer.

That 80 cents per 10 days in Jacksonville.

You guys are at ~$0.08/kWh? Cheap. I think I am ~$.014.

If the chiller jumps to running 12 hours a day (3X more) that will be $2.28 per 10 days in Jacksonville.

It may be even less. The 2.8 is probably peak/start current. Chilling is cheap.

In contrast, once again, nothing is wrong with chest freezers. However, if they have 20-30 gallons of fermenting beer--they run near or totally constantly.

however, you have failed to convince me (or likely anyone) that the chest freezer is more efficient to use for that volume of beer.

I was talking, and still am, about the size of chiller needed to do that. If a freezer with a 4 amp motor can't keep up, even given its issues at high loads, it is doubtful that an aq chiller at ~1/4 the energy input, even with its advantages, could keep up either, and the coil to beer bit is not relevant here. This assumes both can keep up. It would need to have a COP 4X the freezer. It could be possible, but it is not a clear cut case that doesn't need some experimental verification.

That said, the my secondary fermentation will be in chest freezers. It has nothing do with efficiency. My secondaries/serving vessels are corny kegs and I can fit butt load of them in the chest freezers. The chest freezers do not run all the time to maintain non-fermenting beer at any temperature. Chest freezers, IMO, for that purpose, are ideal.

This is why your lager issue confuses me. Ferming a lager at ~50F should be so low power to be almost equivalent to maintaining finished beer at 50F. If you put them in there hot, and tried to ramp to 50F, I could see issues with a runaway ferm the freezer would have trouble with dropping.

Chest freezers also work well for primary fermenting--the compressor just runs more than this chiller set up and the temperature control does not respond as quickly.

It is different than my experience, but I also don't have a 1.8A plate rating. Fans help a lot with transfer rates, and why fridges 'as built' are probably a better choice for high volumes. For crashing, the aq chiller, especially with the bath/battery is for sure better down to some beer-chill fluid temp diff. Going past that temp, or as the glycol system nears the temp, the fridge based setup will start to outperform it due to its -10F temp floor.