I have started my list and checking it 1000 times.

I have a spikebrewing pot and am doing extract brews for now. Looking to do full boil 5 gal batches.

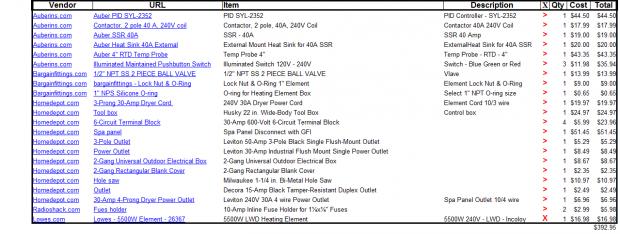

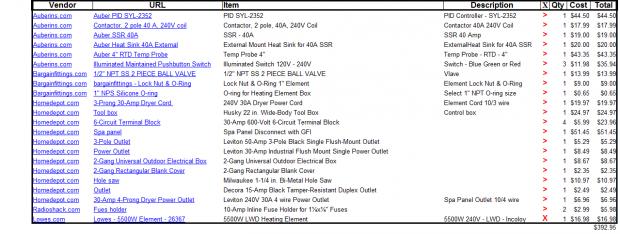

Here is my list let me know if I have missed something. I want to start basic but leave room to upgrade if or when I go all grain.

I have a spikebrewing pot and am doing extract brews for now. Looking to do full boil 5 gal batches.

Here is my list let me know if I have missed something. I want to start basic but leave room to upgrade if or when I go all grain.