Yes, the silicone picked up a smell. If I take them off and smell them they will have hops smells after cleaning.Are you removing all of the Tri clamps, fittings, and gaskets after CIP to clean them?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doubling Down: SS Brewtech Conical + FTSS + Glycol Power Pack

- Thread starter mfabe

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

Yes, the silicone picked up a smell. If I take them off and smell them they will have hops smells after cleaning.

I just clean and soak all the gaskets, fittings and valves in PBW. Rinse it all real good then let them sit in Starsan for a little while and reassemble.

Morrey

Well-Known Member

I bought a couple of those Teflon gaskets to use on the racking arm to help it glide more easily when rotated. It is a harder material and may not pick up odors as readily.

Same here. I worry they will leak since they are hard, but they don't seem toI bought a couple of those Teflon gaskets to use on the racking arm to help it glide more easily when rotated. It is a harder material and may not pick up odors as readily.

PTFE is a hard yet very flexible fluoropolymer, it is hydrophobic and likely with being snuggled down will out survive silicone gaskets in terms of not picking up flavors and odors and not being destroyed.Same here. I worry they will leak since they are hard, but they don't seem to

Morrey

Well-Known Member

Just an update of sorts:

Living in balmy SC, I have always focused on the cooling side of my fermenters with not so much concern over the heating side. I always had heat control but typically only needed it for very mild situations...until this winter. I had a 14G ale in the tank when our first wave of cold came through with temps in the single digits at night and highs right at freezing in the day. With my Ss Uni-tank's FTSs controller set at 65F, I was worried my tank would not keep at this temp in my outdoor (non-temp controlled) brew-cave. I draped a mover's blanket over the neoprene jacket for added insulation in hopes this may help at least somewhat. To my surprise, the wort temperature never did dip low as I expected and the FTSs system kept the temps right on target! Impressive.

My other update is I decided the 14G uni needed a little brother so I ordered the 7G uni. This proves to be a good choice for me personally since I have the chiller that can support multiple fermenters plus an assortment of TC clamps and accessories that can work on either fermenter. I like this small tank for single keg batches and use the bigger tank for double keg batches. I find this tank to be easy to work with and a good choice since I am already becoming adept at CIP cleaning and working the TC fittings which takes a bit of finesse.

I had a slight problem with the 7G tank in that the ball valve in the carb stone was not sealing and letting pressure escape. A quick email to Ss and they had a replacement fitting sent priority to fix the problem. Excellent customer service, and this makes me glad I have several Ss products now.

Living in balmy SC, I have always focused on the cooling side of my fermenters with not so much concern over the heating side. I always had heat control but typically only needed it for very mild situations...until this winter. I had a 14G ale in the tank when our first wave of cold came through with temps in the single digits at night and highs right at freezing in the day. With my Ss Uni-tank's FTSs controller set at 65F, I was worried my tank would not keep at this temp in my outdoor (non-temp controlled) brew-cave. I draped a mover's blanket over the neoprene jacket for added insulation in hopes this may help at least somewhat. To my surprise, the wort temperature never did dip low as I expected and the FTSs system kept the temps right on target! Impressive.

My other update is I decided the 14G uni needed a little brother so I ordered the 7G uni. This proves to be a good choice for me personally since I have the chiller that can support multiple fermenters plus an assortment of TC clamps and accessories that can work on either fermenter. I like this small tank for single keg batches and use the bigger tank for double keg batches. I find this tank to be easy to work with and a good choice since I am already becoming adept at CIP cleaning and working the TC fittings which takes a bit of finesse.

I had a slight problem with the 7G tank in that the ball valve in the carb stone was not sealing and letting pressure escape. A quick email to Ss and they had a replacement fitting sent priority to fix the problem. Excellent customer service, and this makes me glad I have several Ss products now.

philly224

Well-Known Member

Just read through a lot of this thread. What kind of luck do you think i would have cooling the spike cf5 conical with five gallon batches with the keg in the chest freezer method? I'd be fine with not being able to cold crash but it would be nice to lager/get low enough temps to force carb with the carb stone.

I am leaning towards this or the aquarium chiller method currently. The fermenter will be in a 60 degree basement.

I am leaning towards this or the aquarium chiller method currently. The fermenter will be in a 60 degree basement.

Morrey

Well-Known Member

Just read through a lot of this thread. What kind of luck do you think i would have cooling the spike cf5 conical with five gallon batches with the keg in the chest freezer method? I'd be fine with not being able to cold crash but it would be nice to lager/get low enough temps to force carb with the carb stone.

I am leaning towards this or the aquarium chiller method currently. The fermenter will be in a 60 degree basement.

I have some thoughts to share, but first wanted to ask what you meant exactly by saying "Keg" in the chest freezer method? I'm assuming you mean "conical" in the chest freezer, just making sure before I go into a detailed answer.

philly224

Well-Known Member

I have some thoughts to share, but first wanted to ask what you meant exactly by saying "Keg" in the chest freezer method? I'm assuming you mean "conical" in the chest freezer, just making sure before I go into a detailed answer.

I want to avoid putting the conical in the chest freezer cause it will limit my access to all the valves and make everything hard to get to. I meant filling up a keg with water and running tubing out of the chest freezer to the chiller in the top of the conical.

Dockside_Brewing

Well-Known Member

- Joined

- Oct 29, 2017

- Messages

- 192

- Reaction score

- 86

If you don't want to spend the money on a glycol chiller and you don't want to cold crash, the aquarium chiller would be the next easiest solution. You could probably get away with a 1/10th HP and those are around $300.00 plus the pump. If you have room in your keezer, the keg would be the cheapest route all you would need is the pump and temp control.

Morrey

Well-Known Member

I want to avoid putting the conical in the chest freezer cause it will limit my access to all the valves and make everything hard to get to. I meant filling up a keg with water and running tubing out of the chest freezer to the chiller in the top of the conical.

Exactly my thoughts as well, hence my question regarding valve access in a chest freezer.

You could always run a glycol/water mix in a keg in your freezer with a sub pump to the cooling coils. You can use a 2x6 for a collar and drill holes for the lines to your conical. If you also have kegs in the keezer, obviously you can chill the fermenter to 35F so crashing is possible.

philly224

Well-Known Member

Exactly my thoughts as well, hence my question regarding valve access in a chest freezer.

You could always run a glycol/water mix in a keg in your freezer with a sub pump to the cooling coils. You can use a 2x6 for a collar and drill holes for the lines to your conical. If you also have kegs in the keezer, obviously you can chill the fermenter to 35F so crashing is possible.

I'm thinking I wouldn't be able to chill it all the way to 35 with this method. I would have to leave the freezer at about 33 so my other beer didn't freeze as well. I guess I don't have much to lose trying this method as I would be able to reuse the pump for an aquarium chiller setup.

Morrey

Well-Known Member

I'm thinking I wouldn't be able to chill it all the way to 35 with this method. I would have to leave the freezer at about 33 so my other beer didn't freeze as well. I guess I don't have much to lose trying this method as I would be able to reuse the pump for an aquarium chiller setup.

I think this will work fine. I bring my beer down slowly when I "crash" so the word crash is basically a misnomer. I feel that crashing hard sets up the potential for haze formation (debatable but the way I roil), so I step it down slowly 5F every 3-4 hours. This slow step will allow the water/glycol mix to recover as it lowers slowly.

By mixing some glycol into the water, I think you'll be just fine. Those small fountain pumps from HD will plug right into an Inkbird or similar atc device.

I am also the proud new owner of two 7 gallon Ssbrewtech unitanks and their glycol chiller. I started another thread but seems like all the action is in here  . I had several issues with one of the tanks and after contacting customer service and seeing what they were willing to discount I decided to send back the tank for an exchange. Hardest part was getting it all packed back up the way it came. One of my temp controllers was dinged up as well so back it went to.

. I had several issues with one of the tanks and after contacting customer service and seeing what they were willing to discount I decided to send back the tank for an exchange. Hardest part was getting it all packed back up the way it came. One of my temp controllers was dinged up as well so back it went to.

I brew on the covered porch that runs the length of my house (it’s plumbed in for ng) and had to carry brewbucket thru the house to the garage fermenting fridge. Not anymore! I just wheel the unitank over and fill er from the bottom up with wort, and then over to the fermenting side of the porch they go. I left some starsans in both over the cold snap that we had when it got down to 17. Both fermenters held temp @65ish degrees for multiple days. If the glycol chiller is as efficient during our hot summers I will be even more impressed. Hell I got room for 2more

Unitanks on the chiller

Have a pliney clone in there now that tastes just like the original. Did my first mini dump after two days. And will do another at the end of day 5. Then in go the dry hops for 5 more days a cold crash and another dump to get rid of them and then finally finish up carbing with the stone in tank. I’m toying with the idea of actually using my 1 micron cartridge filter for the closed transfer to the keg. Used this between kegs a few times but what a pia that was. So it got shelved lol. Picked up a liquid out 1.5” tc to use for this very purpose.

Anyway I’m happy. My beer will taste even better with the cold side improvement. And customer service at Ss took good care of me. If your on the fence and have the $ to spend I say do it and don’t look back.

I do want to know how y’all are going from a sumppump to the cip ball. Annnnnnd if you are taking the cooling coils out or leaving them in. One more thing..how to clean out the blowoff tube? I am assuming that the best way to do this is to run for a few min with pwb and the pump up through there then switching to the cip ball at the top. If so can the pressure gauge remain on or should you take it off? What’s the liquid in that gauge for anyway..made out of?

Czmkid

I brew on the covered porch that runs the length of my house (it’s plumbed in for ng) and had to carry brewbucket thru the house to the garage fermenting fridge. Not anymore! I just wheel the unitank over and fill er from the bottom up with wort, and then over to the fermenting side of the porch they go. I left some starsans in both over the cold snap that we had when it got down to 17. Both fermenters held temp @65ish degrees for multiple days. If the glycol chiller is as efficient during our hot summers I will be even more impressed. Hell I got room for 2more

Unitanks on the chiller

Have a pliney clone in there now that tastes just like the original. Did my first mini dump after two days. And will do another at the end of day 5. Then in go the dry hops for 5 more days a cold crash and another dump to get rid of them and then finally finish up carbing with the stone in tank. I’m toying with the idea of actually using my 1 micron cartridge filter for the closed transfer to the keg. Used this between kegs a few times but what a pia that was. So it got shelved lol. Picked up a liquid out 1.5” tc to use for this very purpose.

Anyway I’m happy. My beer will taste even better with the cold side improvement. And customer service at Ss took good care of me. If your on the fence and have the $ to spend I say do it and don’t look back.

I do want to know how y’all are going from a sumppump to the cip ball. Annnnnnd if you are taking the cooling coils out or leaving them in. One more thing..how to clean out the blowoff tube? I am assuming that the best way to do this is to run for a few min with pwb and the pump up through there then switching to the cip ball at the top. If so can the pressure gauge remain on or should you take it off? What’s the liquid in that gauge for anyway..made out of?

Czmkid

Morrey

Well-Known Member

Sounds like Ss BT Customer Service took care of you too. I have used their products for several years and am totally brand loyal at this point.I am also the proud new owner of two 7 gallon Ssbrewtech unitanks and their glycol chiller. I started another thread but seems like all the action is in here. I had several issues with one of the tanks and after contacting customer service and seeing what they were willing to discount I decided to send back the tank for an exchange. Hardest part was getting it all packed back up the way it came. One of my temp controllers was dinged up as well so back it went to.

I brew on the covered porch that runs the length of my house (it’s plumbed in for ng) and had to carry brewbucket thru the house to the garage fermenting fridge. Not anymore! I just wheel the unitank over and fill er from the bottom up with wort, and then over to the fermenting side of the porch they go. I left some starsans in both over the cold snap that we had when it got down to 17. Both fermenters held temp @65ish degrees for multiple days. If the glycol chiller is as efficient during our hot summers I will be even more impressed. Hell I got room for 2more

Unitanks on the chiller

Have a pliney clone in there now that tastes just like the original. Did my first mini dump after two days. And will do another at the end of day 5. Then in go the dry hops for 5 more days a cold crash and another dump to get rid of them and then finally finish up carbing with the stone in tank. I’m toying with the idea of actually using my 1 micron cartridge filter for the closed transfer to the keg. Used this between kegs a few times but what a pia that was. So it got shelved lol. Picked up a liquid out 1.5” tc to use for this very purpose.

Anyway I’m happy. My beer will taste even better with the cold side improvement. And customer service at Ss took good care of me. If your on the fence and have the $ to spend I say do it and don’t look back.

I do want to know how y’all are going from a sumppump to the cip ball. Annnnnnd if you are taking the cooling coils out or leaving them in. One more thing..how to clean out the blowoff tube? I am assuming that the best way to do this is to run for a few min with pwb and the pump up through there then switching to the cip ball at the top. If so can the pressure gauge remain on or should you take it off? What’s the liquid in that gauge for anyway..made out of?

Czmkid

Ss sells a 6" to 3" TC adaptor that allows you to remove the cooling coils for CIP cleaning. If you leave the coils in place they break up the CIP spray pattern making cleaning less effective. I clean the coil in a bucket of PBW and let the micro ball do the rest.

I soak my BO tube assembly in PBW separately after CIP cleaning. Then I shoot a garden hose thru it to blow out any loose material that may be stuck in the cane. Cleaning is always the PITA aspect of any brewing system. I just wipe the pressure gauge off and shoot star san on it so I don't take the chance of damage. But, I think it is pretty sturdy none the less....and I have soaked mine before with no ill effects.

I'm thinking I wouldn't be able to chill it all the way to 35 with this method. I would have to leave the freezer at about 33 so my other beer didn't freeze as well. I guess I don't have much to lose trying this method as I would be able to reuse the pump for an aquarium chiller setup.

I tried doing this initially, but it didn't work well. I filled a corny keg with cold water and would keep the freezer at just above freezing. The issue is once you warmed the corny up during chilling, it didn't register right away in the freezer (if you keep temp probe for freezer in freezer). If you move the temp probe to the corney keg and use that as your indicator for freezer to go on and off, you end up running a lot and for a long time. It takes some time to chill the water up again (at least in mine it did). It was just too inefficient. I could barely keep anything at 60 degrees let alone lower.

I ended up buying an aquarium chiller for $300 and that worked fine down to upper 40's, but was kinda of messy and a pain (you need a cooler and all the fittings, etc.). I finally broke down and got the glycol chiller from Penguin. I wish now I had started there... sooo much nicer and easier to use. Buy once, cry once.

Morrey

Well-Known Member

I tried doing this initially, but it didn't work well. I filled a corny keg with cold water and would keep the freezer at just above freezing. The issue is once you warmed the corny up during chilling, it didn't register right away in the freezer (if you keep temp probe for freezer in freezer). If you move the temp probe to the corney keg and use that as your indicator for freezer to go on and off, you end up running a lot and for a long time. It takes some time to chill the water up again (at least in mine it did). It was just too inefficient. I could barely keep anything at 60 degrees let alone lower.

I ended up buying an aquarium chiller for $300 and that worked fine down to upper 40's, but was kinda of messy and a pain (you need a cooler and all the fittings, etc.). I finally broke down and got the glycol chiller from Penguin. I wish now I had started there... sooo much nicer and easier to use. Buy once, cry once.

Nothing like your voice of experience to say what will work...or not work in this case.

Of course I have the Penguin chiller like yours which we have discussed. I love it, cried once...and never looked back. I feel a person can spend time, energy and money trying to rig up some sort of makeshift project only to end up buying a glycol chiller after all else is less than satisfactory. Totally agreed, and while others may say no need to do this, I am 100% glad I did.

Just wondering....Say he used a small freezer containing a keg filled with glycol/water mix with ATC probed into the glycol. Nothing else in this freezer except the glycol filled keg set as low as the freezer would take it w/o freezing. Would the indirect ambient cooling power of this setup be effective enough to handle fermenter cooling or potentially crashing? After thinking about the OP's question, I'm wondering if anything else could be suggested in case he doesn't want to invest in a GC right now.

Just wondering....Say he used a small freezer containing a keg filled with glycol/water mix with ATC probed into the glycol. Nothing else in this freezer except the glycol filled keg set as low as the freezer would take it w/o freezing. Would the indirect ambient cooling power of this setup be effective enough to handle fermenter cooling or potentially crashing? After thinking about the OP's question, I'm wondering if anything else could be suggested in case he doesn't want to invest in a GC right now.

No, I don't think so. I only had the keg and water in the freezer and it just took way too long to chill it back down. If you re-read the first post of this entire thread (the OP), you will see that was his exact experience too. I can vouch for the OP's experience exactly.

I considered the penguin or SSBrewtech glycol chiller but ultimately decided to make it. One $30 Frigidaire basic ac unit off Craigslist, a smaller quality igloo cooler and a homemade STC 1000 controller and it was perfect. I control the glycol with more than enough accuracy and can easily go super cold. I tend to keep the glycol bath at 14 degrees during fermentation. Works perfect, saved 800 bucks and is zero maintenance at all.

philly224

Well-Known Member

I tried doing this initially, but it didn't work well. I filled a corny keg with cold water and would keep the freezer at just above freezing. The issue is once you warmed the corny up during chilling, it didn't register right away in the freezer (if you keep temp probe for freezer in freezer). If you move the temp probe to the corney keg and use that as your indicator for freezer to go on and off, you end up running a lot and for a long time. It takes some time to chill the water up again (at least in mine it did). It was just too inefficient. I could barely keep anything at 60 degrees let alone lower.

I ended up buying an aquarium chiller for $300 and that worked fine down to upper 40's, but was kinda of messy and a pain (you need a cooler and all the fittings, etc.). I finally broke down and got the glycol chiller from Penguin. I wish now I had started there... sooo much nicer and easier to use. Buy once, cry once.

Thanks. I think you have convinced me not to try keg in freezer then. Still considering the aquarium chiller route though upper 40s sounds okay to me. How hot was the room your fermenter was in?

Morrey

Well-Known Member

Of co

Of course I have a Penguin which is all I need, but would you mind posting a pic of your DIY chiller? I'm interested in this project as my Brother In Law wants some sort of cooling system other than his freezer with an ATC.I considered the penguin or SSBrewtech glycol chiller but ultimately decided to make it. One $30 Frigidaire basic ac unit off Craigslist, a smaller quality igloo cooler and a homemade STC 1000 controller and it was perfect. I control the glycol with more than enough accuracy and can easily go super cold. I tend to keep the glycol bath at 14 degrees during fermentation. Works perfect, saved 800 bucks and is zero maintenance at all.

Thanks. I think you have convinced me not to try keg in freezer then. Still considering the aquarium chiller route though upper 40s sounds okay to me. How hot was the room your fermenter was in?

My basement is pretty much 68 year round.

philly224

Well-Known Member

Does anyone use a cooler with just ice in it? How often do you have to change the ice? I was thinking about doing that until I can score an aquarium chiller off craigslist for cheap. That way I can just buy the cooler/pump for now and save my wallet a little pain.

Morrey

Well-Known Member

Does anyone use a cooler with just ice in it? How often do you have to change the ice? I was thinking about doing that until I can score an aquarium chiller off craigslist for cheap. That way I can just buy the cooler/pump for now and save my wallet a little pain.

I did that at first. ^^^

Several factors influence how often you change ice, and I'll suggest frozen water bottles. Gatorade bottles, large and small ones, are good to use to freeze water and change out to refreeze when thawed.

In the summer, and in a warm outdoor shed, I changed twice a day. The larger the cooler and the more frozen bottles in the cooler, the less often you'll change out. High quality coolers feature more insulation, and the more you fill said cooler to capacity (less headspace), the longer your ice will last. In cooler climates or if used indoors in a moderate climate, you may be able to get away with one change per day or possibly even longer than that. During the height of fermentation, exothermic heat is created making ice melt faster. Later in the fermentation, your ice will last longer if ambient conditions stay the same.

This is a good way to get started and not an overly expensive method. Obviously the glycol chiller is the cat's meow, but the cooler and ice/frozen bottle method gets the job done. You may not be able to cold crash with this method, at least I couldn't with my setup, but it will control fermentation temps on ales and lagers pretty well.

Last edited:

Was looking at different pressurized fermentation threads and ran across something that @DaWhip said about saving co2.

“

This is pure genius! I kinda feel like I’m flying by the seat of my pants fermenting under pressure. Have been brewing for 10 years just without the new toys. Just dumped yeast and threw in the dryhops in on my first batch. Active fermentation has just started in my second uni. I never thought to buy a gas out 1.5 tc post and run that to a gas out post on a corney to collect co2. Is this co2 clean? Pure? Ok to use? I know one thing it’s free!

I also have a few questions and I hope it’sok if I place them in here since they deal with pressurized fermentation’s.

Should I be waiting to close my blowoff valve until after I dump my yeast and trub and or dry hop additions to the unitank?

Or

Should I be closing my blowoff valve when fermentation starts and letting the 15 psi PRV on 3” tc handle the pressure relief? If so then how does one dump trub, yeast, hop additions, without making a huge mess? I’m guessing to crack the blowoff valve open to release co2 pressure and then letting gravity and the butterfly do the rest. In other words should I do this now with the batch that just started fermenting.

[url=https://flic.kr/p/23UK1NB] [/url]

[/url]

“

ee.”I also save the CO2 in my empty kegs and can use them to push beer instead of my CO2 tank. Also, all of my empty kegs are already flushed with CO2 for fr

This is pure genius! I kinda feel like I’m flying by the seat of my pants fermenting under pressure. Have been brewing for 10 years just without the new toys. Just dumped yeast and threw in the dryhops in on my first batch. Active fermentation has just started in my second uni. I never thought to buy a gas out 1.5 tc post and run that to a gas out post on a corney to collect co2. Is this co2 clean? Pure? Ok to use? I know one thing it’s free!

I also have a few questions and I hope it’sok if I place them in here since they deal with pressurized fermentation’s.

Should I be waiting to close my blowoff valve until after I dump my yeast and trub and or dry hop additions to the unitank?

Or

Should I be closing my blowoff valve when fermentation starts and letting the 15 psi PRV on 3” tc handle the pressure relief? If so then how does one dump trub, yeast, hop additions, without making a huge mess? I’m guessing to crack the blowoff valve open to release co2 pressure and then letting gravity and the butterfly do the rest. In other words should I do this now with the batch that just started fermenting.

[url=https://flic.kr/p/23UK1NB]

[/url]

[/url]Tozzi

Active Member

I've just discovered this thread by pure lucky coincidence, and I found some extremely helpful info here!

Thanks a lot for that!

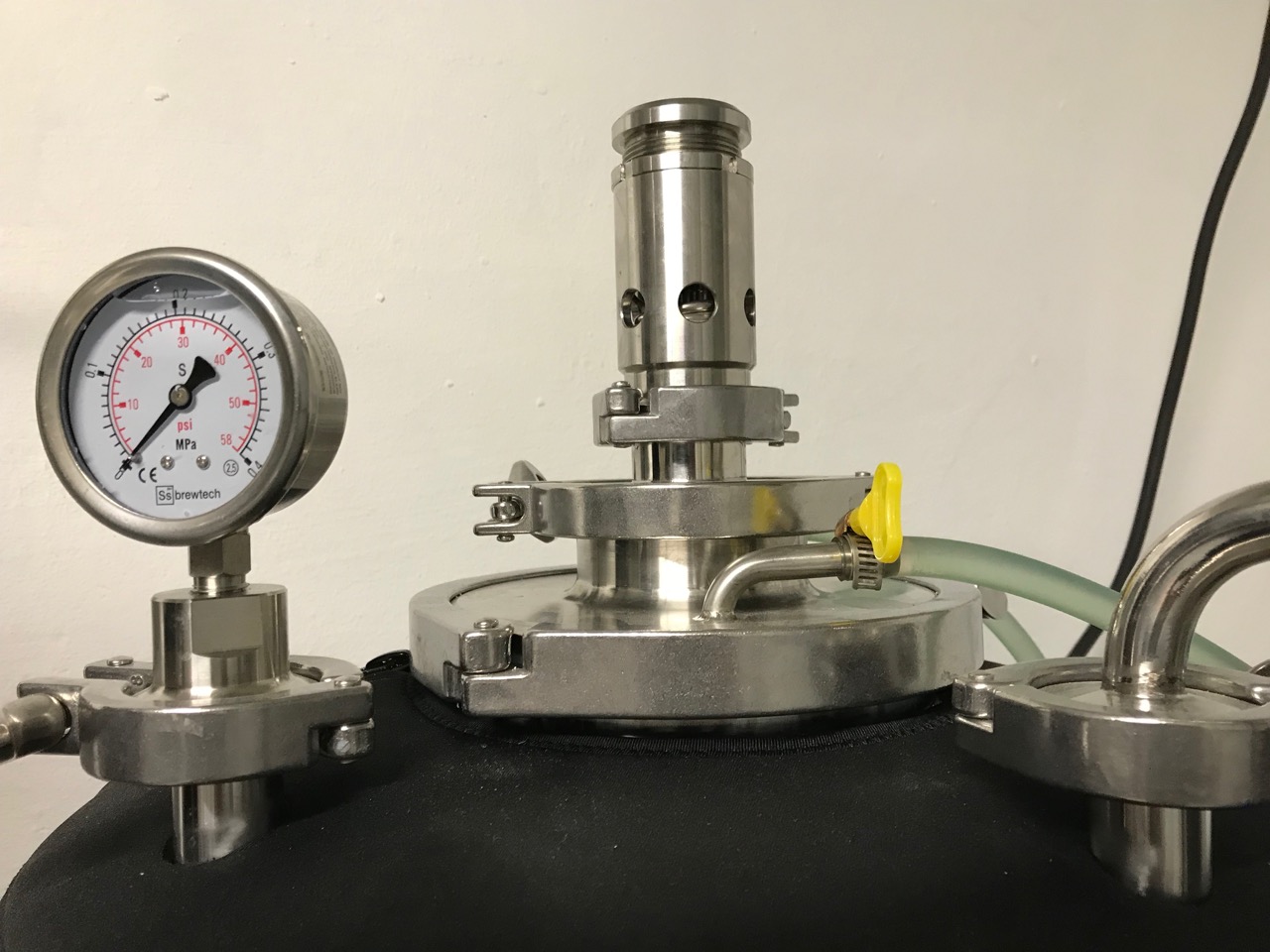

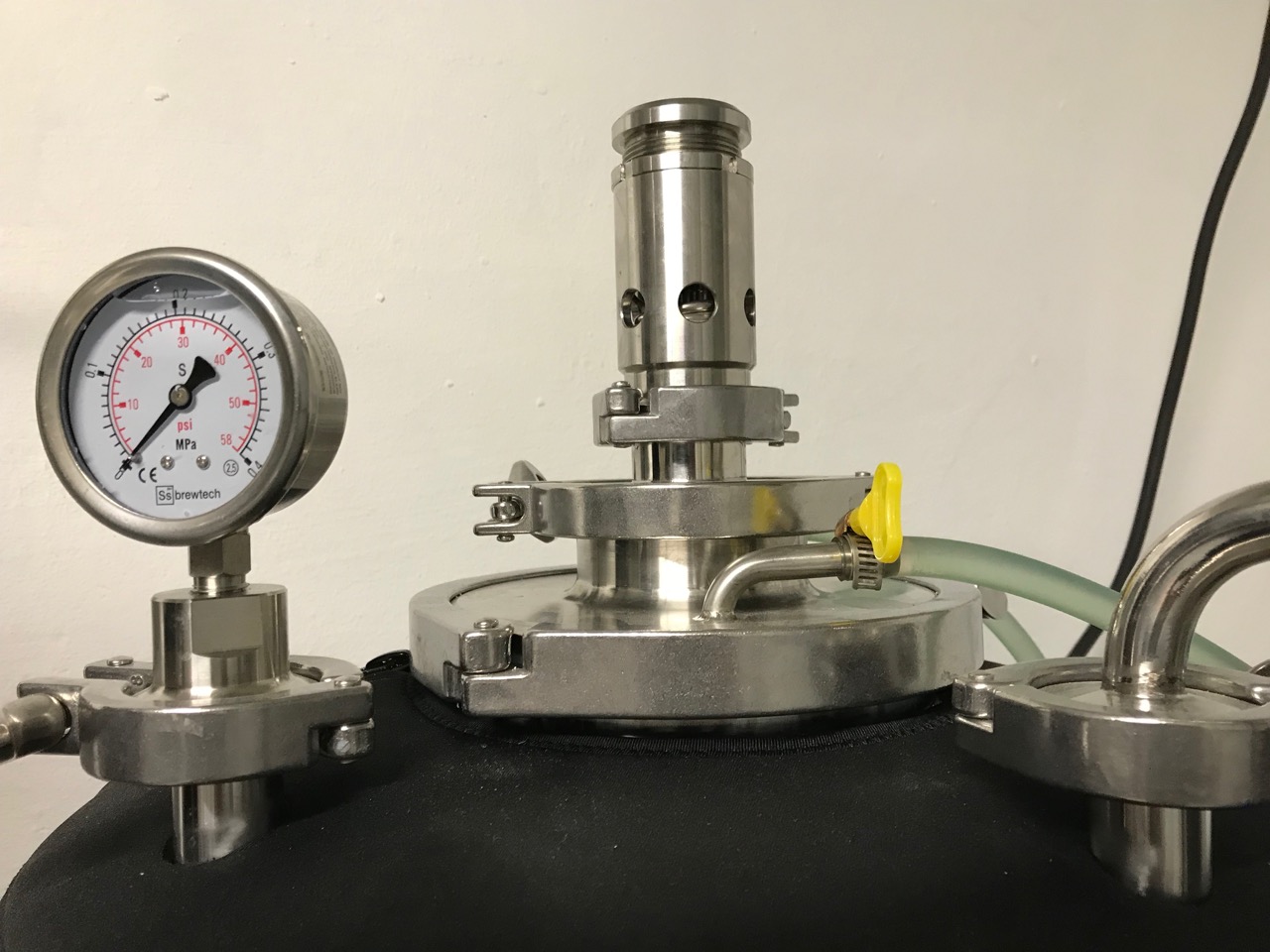

I've been a huge fan of Ss Brewtech products for quite a while and I own two 7 Gal Chronicals, a 10 Gal Brite Tank which is currently being used for lagering a "Maibock", the 1/2 BBL Chronical (currently pre-fermenting a Red Flanders which will soon be exposed to the "bugs", only after racking it into a simpler vessel, of course), with the latest and greatest addition being my beloved 1/2 BBL Unitank.

Here's a picture of part of my setup:

I live and brew in Germany, so unfortunately I've currently got no access to any affordable Glycol Chillers (we're technologically decades behind you guys regarding homebrewing) and am eagerly awaiting the Grainfather Chiller to finally hit the shelves, which will probably be the first product of its kind on a homebrewer's scale and price range to become available here...

Meanwhile I'm using an Aquarium Chiller, which at least allows me to achieve lagering temperatures (but no cold crash).

Currently I have a Bohemian Lager/Pilsener fermenting inside my Unitank (using Imperial's L28 "Urkel" Yeast) and am slowly approaching the end of primary fermentation (so far not pressurized, at 52F/11˚C).

Now, since it's bottom-fermenting at lager temperature, I'd of course like to take the opportunity and carbonate it naturally.

Unfortunately, I didn't check at what pressure the Unitank's PRV opens.

Anyone here who can give me a clue on this? I've googled a lot and searched all the forums I know but didn't find any reliable info on this.

I did test it on the Brite Tank, but stopped at 30 PSI, where the PRV still didn't budge...

Any recommendations on how to fit a proper spunding valve onto the Unitank?

Or can the standard PRV be adjusted?

Would this item work better?

https://www.aliexpress.com/item/San...SS304-Stainless-Steel-15-PSI/32455129858.html

Thanks a lot for that!

I've been a huge fan of Ss Brewtech products for quite a while and I own two 7 Gal Chronicals, a 10 Gal Brite Tank which is currently being used for lagering a "Maibock", the 1/2 BBL Chronical (currently pre-fermenting a Red Flanders which will soon be exposed to the "bugs", only after racking it into a simpler vessel, of course), with the latest and greatest addition being my beloved 1/2 BBL Unitank.

Here's a picture of part of my setup:

I live and brew in Germany, so unfortunately I've currently got no access to any affordable Glycol Chillers (we're technologically decades behind you guys regarding homebrewing) and am eagerly awaiting the Grainfather Chiller to finally hit the shelves, which will probably be the first product of its kind on a homebrewer's scale and price range to become available here...

Meanwhile I'm using an Aquarium Chiller, which at least allows me to achieve lagering temperatures (but no cold crash).

Currently I have a Bohemian Lager/Pilsener fermenting inside my Unitank (using Imperial's L28 "Urkel" Yeast) and am slowly approaching the end of primary fermentation (so far not pressurized, at 52F/11˚C).

Now, since it's bottom-fermenting at lager temperature, I'd of course like to take the opportunity and carbonate it naturally.

Unfortunately, I didn't check at what pressure the Unitank's PRV opens.

Anyone here who can give me a clue on this? I've googled a lot and searched all the forums I know but didn't find any reliable info on this.

I did test it on the Brite Tank, but stopped at 30 PSI, where the PRV still didn't budge...

Any recommendations on how to fit a proper spunding valve onto the Unitank?

Or can the standard PRV be adjusted?

Would this item work better?

https://www.aliexpress.com/item/San...SS304-Stainless-Steel-15-PSI/32455129858.html

Last edited:

philly224

Well-Known Member

I've just discovered this thread by pure lucky coincidence, and I found some extremely helpful info here!

Thanks a lot for that!

I've been a huge fan of Ss Brewtech products for quite a while and I own two 7 Gal Chronicals, a 10 Gal Brite Tank which is currently being used for lagering a "Maibock", the 1/2 BBL Chronical (currently pre-fermenting a Red Flanders which will soon be exposed to the "bugs", only after racking it into a simpler vessel, of course), with the latest and greatest addition being my beloved 1/2 BBL Unitank.

Here's a picture of part of my setup:

View attachment 555869

I live and brew in Germany, so unfortunately I've currently got no access to any affordable Glycol Chillers (we're technologically decades behind you guys regarding homebrewing) and am eagerly awaiting the Grainfather Chiller to finally hit the shelves, which will probably be the first product of its kind on a homebrewer's scale and price range to become available here...

Meanwhile I'm using an Aquarium Chiller, which at least allows me to achieve lagering temperatures (but no cold crash).

Currently I have a Bohemian Lager/Pilsener fermenting inside my Unitank (using Imperial's L28 "Urkel" Yeast) and am slowly approaching the end of primary fermentation (so far not pressurized, at 52F/11˚C).

Now, since it's bottom-fermenting at lager temperature, I'd of course like to take the opportunity and carbonate it naturally.

Unfortunately, I didn't check at what pressure the Unitank's PRV opens.

Anyone here who can give me a clue on this? I've googled a lot and searched all the forums I know but didn't find any reliable info on this.

I did test it on the Brite Tank, but stopped at 30 PSI, where the PRV still didn't budge...

Any recommendations on how to fit a proper spunding valve onto the Unitank?

Or can the standard PRV be adjusted?

Would this item work better?

https://www.aliexpress.com/item/San...SS304-Stainless-Steel-15-PSI/32455129858.html

Nice setup!!! Curious what the lowest temp you can get down to with an aquarium chiller is?

Tozzi

Active Member

About 50 (4.5˚C)...Curious what the lowest temp you can get down to with an aquarium chiller is?

Morrey

Well-Known Member

I have a 7G and a 14G Uni. I tested the PRV's on both, and both relieved exactly at 18 psi. The tanks are rated for 30 psi burst pressure, but the PRV is set for 18 psi and operated exactly as designed.Unfortunately, I didn't check at what pressure the Unitank's PRV opens.

Anyone here who can give me a clue on this? I've googled a lot and searched all the forums I know but didn't find any reliable info on this.

I did test it on the Brite Tank, but stopped at 30 PSI, where the PRV still didn't budge...

Tozzi

Active Member

Thank you, Morrey!

Funnily I just found out by myself, 5 minutes ago.

Wearing my glasses for a change, I saw that the PRV says "0.12 MPa", which equals 1.2 Bar, which in turn are ~17.5 PSI.

Glad you confirmed this!

How much does it blow off, once triggered (hysteresis)?

I guess, it will close as soon as it's back down to 17 psi?

That would be ideal for naturally carbonating bottom-fermented (lager) beers.

Also, 1.2 Bars are well within the recommended range as mentioned by Chris White and John Blichmann in the latest BeerSmith podcast.

I love my Unitank, now even more so.

Funnily I just found out by myself, 5 minutes ago.

Wearing my glasses for a change, I saw that the PRV says "0.12 MPa", which equals 1.2 Bar, which in turn are ~17.5 PSI.

Glad you confirmed this!

How much does it blow off, once triggered (hysteresis)?

I guess, it will close as soon as it's back down to 17 psi?

That would be ideal for naturally carbonating bottom-fermented (lager) beers.

Also, 1.2 Bars are well within the recommended range as mentioned by Chris White and John Blichmann in the latest BeerSmith podcast.

I love my Unitank, now even more so.

Speaking of lagers, with this unitank, are you guys planning on going to a trub/yeast dump. It have one going now at 48 degrees, no dry hopping, 15 points away from fg. Not sure when I want to raise to 65 degrees or if I should attempt a yeast dump. It's still way too active to try it nowThank you, Morrey!

Funnily I just found out by myself, 5 minutes ago.

Wearing my glasses for a change, I saw that the PRV says "0.12 MPa", which equals 1.2 Bar, which in turn are ~17.5 PSI.

Glad you confirmed this!

How much does it blow off, once triggered (hysteresis)?

I guess, it will close as soon as it's back down to 17 psi?

That would be ideal for naturally carbonating bottom-fermented (lager) beers.

Also, 1.2 Bars are well within the recommended range as mentioned by Chris White and John Blichmann in the latest BeerSmith podcast.

I love my Unitank, now even more so.

Tozzi

Active Member

I'm about 12 points away now from FG and will wait until tomorrow.Speaking of lagers, with this unitank, are you guys planning on going to a trub/yeast dump. It have one going now at 48 degrees, no dry hopping, 15 points away from fg. Not sure when I want to raise to 65 degrees or if I should attempt a yeast dump. It's still way too active to try it now

There is still a lot of yeast in suspension from all the CO2, so what I am going to try is to shut the blow off valve, wait until some pressure has built up (a few psi) so that the yeast has a chance to settle. Then I'll dump (hopefully without causing a huge mess) and from then on call it a secondary.

Not sure if I want to raise temperature at all this time. It's a Bohemian, so some diacetyl wouldn't mean disaster. Can't taste any so far, anyway. Initially it had a lot of sulfur, but that's already gone overnight, literally.

As always, YMMV...

Morrey

Well-Known Member

I have been on a WLP 850 Copenhagen kick and am on my 3rd generation with this pitch in a dry styled Kirin lager with rice adjuncts. I did a quick trub dump on day 2, a harvest dump half way through and will do a final dump on Friday. I am crashing now and going from 50F right into crash skipping any raise in temps. I'll do this one last clearing dump on Friday before carbing.

Uni Tanks have really changed the way I approach lagers. Dumping trub/yeast has made my beer clear so I skip the gelatin addition which creates O2 exposure. Skipping the D rest has made no difference that I can detect in the end product provided lagering time is allocated before tapping.

Edit: Tozzi....the PRV relieved at 18 psi, but shut back off quickly once the psi got back below or right at 18 psi. In my first test I left the CO2 pressure from the regulator on and it kept relieving, but once I shut the CO2 tank off, the PRV quit relieving immediately after getting back down to 18 psi.

Uni Tanks have really changed the way I approach lagers. Dumping trub/yeast has made my beer clear so I skip the gelatin addition which creates O2 exposure. Skipping the D rest has made no difference that I can detect in the end product provided lagering time is allocated before tapping.

Edit: Tozzi....the PRV relieved at 18 psi, but shut back off quickly once the psi got back below or right at 18 psi. In my first test I left the CO2 pressure from the regulator on and it kept relieving, but once I shut the CO2 tank off, the PRV quit relieving immediately after getting back down to 18 psi.

Last edited:

Tozzi

Active Member

Yep, I've come to the same conclusion (for now at least).Skipping the D rest has made no difference that I can detect in the end product provided lagering time is allocated before tapping.

To me, one of the greatest advantages the Unitank design offers is that there is no longer any oxygen exposure anymore, if everything's done right. I mean, zero.

Natural carbonation and pressure fermenting are just added bonuses on top of that, along with the super easy oxygenation when you want it, right after pitching the yeast...

There's a lot of money saved there considering all the extras you'd otherwise buy separately.

I only wish they had come out with this one or two years earlier...

EDIT: Ok, so the PRV can definitely be used as a spunding device, as long as 18 psi are what you want. That should be good enough for most people. I've mounted the adjustable one I bought from China anyway (the one I had linked to earlier) and will see where that one takes me. I'll monitor it closely, of course.

Last edited:

Tozzi

Active Member

This is what that one would look like.

I'll get back and tell you how it worked for me with this batch.

I'll get back and tell you how it worked for me with this batch.

I have been on a WLP 850 Copenhagen kick and am on my 3rd generation with this pitch in a dry styled Kirin lager with rice adjuncts. I did a quick trub dump on day 2, a harvest dump half way through and will do a final dump on Friday. I am crashing now and going from 50F right into crash skipping any raise in temps. I'll do this one last clearing dump on Friday before carbing.

Uni Tanks have really changed the way I approach lagers. Dumping trub/yeast has made my beer clear so I skip the gelatin addition which creates O2 exposure. Skipping the D rest has made no difference that I can detect in the end product provided lagering time is allocated before tapping.

I would like to do a trub dump, if don't see it how though. It have a butterfly valve under the dump port then a sight glass under my butterfly valve, then the 90 degree elbow, then a second butterfly valve at the end. When I look at the sight glass, it is crazy active and does not look like trub or yeast, even 1 day in it looked active (made a massive healthy starter). My intention is to be able to fill the sight glass with good yeast and have a TC clamp on the end, then remove and cap the open side. That's why I have the extra butterfly valve on the dump port.

Any suggestions for pulling the yeast to save and doing secondary lager phase in the unitank?

Morrey

Well-Known Member

I would like to do a trub dump, if don't see it how though. It have a butterfly valve under the dump port then a sight glass under my butterfly valve, then the 90 degree elbow, then a second butterfly valve at the end. When I look at the sight glass, it is crazy active and does not look like trub or yeast, even 1 day in it looked active (made a massive healthy starter). My intention is to be able to fill the sight glass with good yeast and have a TC clamp on the end, then remove and cap the open side. That's why I have the extra butterfly valve on the dump port.

Any suggestions for pulling the yeast to save and doing secondary lager phase in the unitank?

I have the butterfly valve attached directly to my tank's dump ferrule. From there, I can attach a 90 degree elbow and/or any other TC fittings on beyond that. By attaching the main butterfly shut off valve directly to the tank, I can change other fittings beyond that easily.

I do three dumps: I trub dump on day 2 or 3 to clear break materials, a yeast harvest dump mid-fermentation, then a final clearing dump after cold crashing right before carbing. These are small dumps of about a pint each.

Pictured is my harvest dump TC fitting from NorCal. I want the jar oriented vertically under the dump port so yeast will settle into the jar and push liquid upward by displacement. I attach the jar, open the valve and give it a couple of hours, then remove jar. Easy. I then reattach any elbows, fittings and desired accessories once the harvest clamp is removed.

EDIT: I failed to mention you'll need to have the tank on leg extensions to allow the harvest jar to orient vertically under the dump valve.

Last edited:

This makes me have conical envyI have the butterfly valve attached directly to my tank's dump ferrule. From there, I can choose attach a 90 degree elbow and/or any other TC fittings on beyond that. By attaching the main butterfly shut off valve directly to the tank, I can change other fittings beyond that easily.

I do three dumps: I trub dump on day 2 or 3 to clear break materials, a yeast harvest dump mid-fermentation, then a final clearing dump after cold crashing right before carbing. These are small dumps of about a pint each.

Pictured is my harvest dump TC fitting from NorCal. I want the jar oriented vertically under the dump port so yeast will settle into the jar and push liquid upward by displacement. I attach the jar, open the valve and give it a couple of hours, then remove jar. Easy. I then reattach any elbows, fittings and desired accessories once the harvest clamp is removed.

View attachment 556013

Morrey

Well-Known Member

Oh I totally understand. I am thinking about a 3rd Uni Tank now. Once you have a chance to use one, you'll wonder how you ever did w/o it. Brewing life is good.This makes me have conical envy

Tozzi

Active Member

Similar threads

- Replies

- 22

- Views

- 1K