I cant get that measurement yet, but its an 5500 watt S element about 2"off the bottom so I haven't worked that part out yet Ill get back to you

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you need a 1 off Stainless part built for your system? Let's discuss it.

- Thread starter Jaybird

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

OK I don't think I can give you a definite measurement, i have a temperature probe in the way too so I think me grinding it to fit would be a better way to go on the spot and it looks like to make it work 4 inches tall would be better because the element is 2.1/2 to the top that would just leave 1/2 " to stabilize and would probably break or bend over time, before I say that how hard is it to grind that stainless anyway

OK I don't think I can give you a definite measurement, i have a temperature probe in the way too so I think me grinding it to fit would be a better way to go on the spot and it looks like to make it work 4 inches tall would be better because the element is 2.1/2 to the top that would just leave 1/2 " to stabilize and would probably break or bend over time, before I say that how hard is it to grind that stainless anyway

Easy. But I can do 90% of the work. Just where the element would contact the ring get me that width and you said 2.5" to the top so I would go 2.625 to be safe. Let me work out a price. I'll PM you.

Cheers

Jay

Jay...I have a 30 gallon mash tun that has a 1/2" npt full port welded in place as a recirculation port. I like to fly sparge. I don't like not being able to put the lid on the top of the tun, so I have not got on-board with the ultimate sparge arm. I am hoping that you could come up with the attachment I would like to use instead. 1/2"npt fitting on ss tubing, going to a 3/8" barb, which would be preferred to be in the center of my tun, albeit there's a snafu in there. I would like to have some kind of bracket or clamping device used , which allows me to attach the tubing going to the recircualtion manifold, to be adjusted and keep it at that level, accordingly to the height of the grain bed, as to not disturb it tremendously while recirculating it. Whatcha think??

How about adding a compression fitting on a corney lid that would accept a thermowell?

How about adding a compression fitting on a corney lid that would accept a thermowell?

How about a threaded 1/2" Full coupling you can screw whatever you want in to it?

Cheers

Jay

Jay...I have a 30 gallon mash tun that has a 1/2" npt full port welded in place as a recirculation port. I like to fly sparge. I don't like not being able to put the lid on the top of the tun, so I have not got on-board with the ultimate sparge arm. I am hoping that you could come up with the attachment I would like to use instead. 1/2"npt fitting on ss tubing, going to a 3/8" barb, which would be preferred to be in the center of my tun, albeit there's a snafu in there. I would like to have some kind of bracket or clamping device used , which allows me to attach the tubing going to the recircualtion manifold, to be adjusted and keep it at that level, accordingly to the height of the grain bed, as to not disturb it tremendously while recirculating it. Whatcha think??

Hmmmm I am only kind of following you. Shoot me a PM with a picture. Just a simple hand drawing would be helpful.

Cheers

Jay

How about a threaded 1/2" Full coupling you can screw whatever you want in to it?

Cheers

Jay

Can you shoot me a quote??

johnwpowell

Well-Known Member

- Joined

- Dec 27, 2016

- Messages

- 258

- Reaction score

- 70

What I need is a 1.5" TC blank with a hole drilled in it to fit an airlock stopper

johnwpowell

Well-Known Member

- Joined

- Dec 27, 2016

- Messages

- 258

- Reaction score

- 70

I'd like an oxygen tank holder. Wall mount strap like a fire extinguisher. Also needs a holster to put the wand into

@Ruint here is your custom adjustable sparge system sir...

Enjoy! Its shipping today

Cheers

Jay

Enjoy! Its shipping today

Cheers

Jay

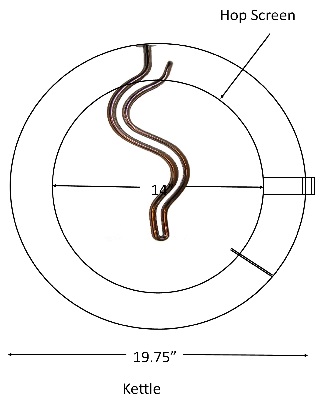

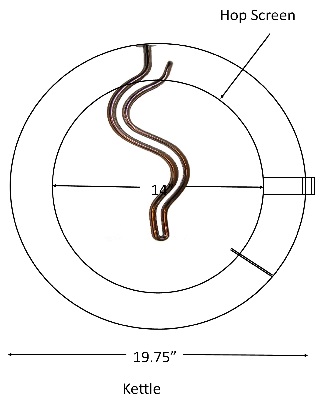

And yet another custom build we did today.

Cheers

Jay

Cheers

Jay

That should definitely do it. Can't wait to put it to the test! Thanks for taking care of this sooo fast Jay! You're awesome!!!

That should definitely do it. Can't wait to put it to the test! Thanks for taking care of this sooo fast Jay! You're awesome!!!

My pleasure! It was a fun little build! The guys in the shop are like, What is this for? lol

Honestly I really like the part idea and I think the squeeze to hold idea is going to open up the doors to a lot of other parts.

Cheers

Jay

johnwpowell

Well-Known Member

- Joined

- Dec 27, 2016

- Messages

- 258

- Reaction score

- 70

Thanks for the 1.5" triclamp with a hole for an airlock stopper. Exactly what I needed. You should just sell this part on your site. I think many others would like it.

I usually use the blow off cane you make for the brew bucket and then switch to an s lock with vodka in it while I cold crash. This part makes it so much easier.

The quality exceeds my expectation. I was expecting something drilled on a bench press but the part was obviously professionally milled. Very very pleased!

If anyone is interested you can see it on my instagram feed.

I usually use the blow off cane you make for the brew bucket and then switch to an s lock with vodka in it while I cold crash. This part makes it so much easier.

The quality exceeds my expectation. I was expecting something drilled on a bench press but the part was obviously professionally milled. Very very pleased!

If anyone is interested you can see it on my instagram feed.

I would like a round disk made of fine mesh stainless that will fit inside your "Keg Dry Hopping Canister/ Filter Thing-a-ma-Jig". The big holes on the top allow hop dust to escape and clog my flow control faucets.

A different lid with the same fine mesh as the canister covering the holes would be OK too.

A different lid with the same fine mesh as the canister covering the holes would be OK too.

I would like a round disk made of fine mesh stainless that will fit inside your "Keg Dry Hopping Canister/ Filter Thing-a-ma-Jig". The big holes on the top allow hop dust to escape and clog my flow control faucets.

A different lid with the same fine mesh as the canister covering the holes would be OK too.

Have you tried trimming your dip tube? Just a half inch off of it can make a huge difference in amount of crud pulled up. Most cornies are made to have the dip tube at the very lowest point, which means it will keep sucking up trub and hop debris.

Have you tried trimming your dip tube? Just a half inch off of it can make a huge difference in amount of crud pulled up. Most cornies are made to have the dip tube at the very lowest point, which means it will keep sucking up trub and hop debris.

It happens at the end of the keg, I think the stuff is floating on the top of the beer.

milldoggy

Well-Known Member

I would like a round disk made of fine mesh stainless that will fit inside your "Keg Dry Hopping Canister/ Filter Thing-a-ma-Jig". The big holes on the top allow hop dust to escape and clog my flow control faucets.

A different lid with the same fine mesh as the canister covering the holes would be OK too.

I had some 300 micron mesh. I use food grade silicon and glued it in.

Now the arbor fab canister, although more, have the same mesh in the lid or no holes(can't remember in my Saturday night state). I have them for keg hopping and worth the cost over the cheap Chinese ones I also have. So quick fix, buy a good canister from them

A good read here

I'm sure jaybird could hook you up with one of these

http://scottjanish.com/my-favorite-way-to-dry-hop-loose-in-primary-and-kegs/

I'm sure jaybird could hook you up with one of these

http://scottjanish.com/my-favorite-way-to-dry-hop-loose-in-primary-and-kegs/

Jay, I'm in need of a part for the brewery I'm at. We just got our grain handling system in place but it's lacking a piece and the company is trying to charge us an arm and a leg for a custom build.

Basically I just need a stainless part that has a 4" triclamp fitting on one end and straight pipe on the other end to connect to our auger discharge. Let me know what you can do for me.

The ID of the discharge tubing looks to be around 3.75".

View attachment ImageUploadedByHome Brew1502820519.806258.jpg

Basically I just need a stainless part that has a 4" triclamp fitting on one end and straight pipe on the other end to connect to our auger discharge. Let me know what you can do for me.

The ID of the discharge tubing looks to be around 3.75".

View attachment ImageUploadedByHome Brew1502820519.806258.jpg

Jay, I'm in need of a part for the brewery I'm at. We just got our grain handling system in place but it's lacking a piece and the company is trying to charge us an arm and a leg for a custom build.

Basically I just need a stainless part that has a 4" triclamp fitting on one end and straight pipe on the other end to connect to our auger discharge. Let me know what you can do for me.

The ID of the discharge tubing looks to be around 3.75".

View attachment 410881

So you need a 4" TC ferrule with a 3-4" long tube welded to it to connect that plastic pipe too? 4" TC should be 4" ID let me know for sure on that measurement

do you need clamps and gaskets as well?

Cheers

Jay

So you need a 4" TC ferrule with a 3-4" long tube welded to it to connect that plastic pipe too? 4" TC should be 4" ID let me know for sure on that measurement

do you need clamps and gaskets as well?

Cheers

Jay

I'll double check tomorrow, but I already know 4" is wrong. Just got back from vacation. Brain isn't ready yet. Do not need clamp and gasket.

Jay it looks like they are going to supply us with the part we need after all. Thanks anyways brother. I'll keep you in mind for the next time!

Jay it looks like they are going to supply us with the part we need after all. Thanks anyways brother. I'll keep you in mind for the next time!

You bet man! Thanks for think of us!

Cheers

Jay

J- trying to find a two port manifold for a DIY o2 assembly. i'd like 1" tubing with two short "instrument" ports so we can pop in a thermometer and our o2 stone laterally to the wort flow.

and maybe a 1" to 3/4" eccentric reducer?

and maybe a 1" to 3/4" eccentric reducer?

J- trying to find a two port manifold for a DIY o2 assembly. i'd like 1" tubing with two short "instrument" ports so we can pop in a thermometer and our o2 stone laterally to the wort flow.

and maybe a 1" to 3/4" eccentric reducer?

PM inbound.

Cheers

Jay

PsychoBiter

Well-Known Member

- Joined

- Feb 17, 2016

- Messages

- 158

- Reaction score

- 31

PM sent

Jay, How about something like what's shown in post #452, except use a thick lock nut in lieu of the TC cap - o-ring side up. Replace the tubing and bulkhead fittings with a removable Camlock F, 2 hi-temp o-rings and another lock nut The use will be as a recirculation flow diverter underneath a LoDo mash cap, a.k.a. SS cake pan.

Jay, How about something like what's shown in post #452, except use a thick lock nut in lieu of the TC cap - o-ring side up. Replace the tubing and bulkhead fittings with a removable Camlock F, 2 hi-temp o-rings and another lock nut The use will be as a recirculation flow diverter underneath a LoDo mash cap, a.k.a. SS cake pan.

Alt

Post up a picture so I can make sure were on the same page.

Cheers

Jay

Let's see if this illustration helps. Still learning this version of TurboCad, so haven't yet drawn the recess for the o-ring. That should be on the outer surface of the hex nut, facing away from the disc. The gap between the nut and the disc is 1/4".

I also need two 0-rings and and a Camlock F as loose parts, which I'll use to sandwich a cake pan between the welded nut assembly and the Camlock F.

View attachment Mash Recirc Fitting.pdf

I also need two 0-rings and and a Camlock F as loose parts, which I'll use to sandwich a cake pan between the welded nut assembly and the Camlock F.

View attachment Mash Recirc Fitting.pdf

What would a 1.5" triclamp 90 degree elbow with a welded on corny keg gas post run me?

Here's my ****ty attempt at a drawing. View attachment ImageUploadedByHome Brew1505314376.499547.jpg

Here's my ****ty attempt at a drawing. View attachment 413895

Ha Ha Ha. Looks good to me man! PM inbound.

Cheers

Jay

Weezy

Well-Known Member

Crushdaley

Active Member

I'm looking for a Thermowell that will fit in a corny keg liquid out dip tube hole and is flared like the dip tube so I can install the post without the poppet and I can run my temp Probe in it and the keg will still be sealed and able to hold pressure. I didn't read this whole thread so if this has been cover already I apologize.

I'm looking for a Thermowell that will fit in a corny keg liquid out dip tube hole and is flared like the dip tube so I can install the post without the poppet and I can run my temp Probe in it and the keg will still be sealed and able to hold pressure. I didn't read this whole thread so if this has been cover already I apologize.

how about a corny lid with a welded in thermowell? jay built me 3, and i think more for someone else.

Crushdaley

Active Member

I was hoping to get about a 16" Thermowell or longer and I wasnt sure the lid would be easy to close with this long of a thermowell

FunkedOut

FunkedOver

- Joined

- Mar 23, 2017

- Messages

- 850

- Reaction score

- 418

How about a corny lid with a QD male welded on?

http://www.norcalbrewingsolutions.com/store/Quick_Disconnect_Male_to_Half_Inch_NPT_Female.html

Then attach an NPT thermowell to a female QD.

Close the lid, then insert thermowell.

How much for a lid with the male QD welded on?

eta: What about welding an 18" thermowell to a barbed QD female?

http://www.norcalbrewingsolutions.com/store/Quick_Disconnect_Female_to_Half_Inch_Barbed.html

How much for the lid/thermowell combo?

http://www.norcalbrewingsolutions.com/store/Quick_Disconnect_Male_to_Half_Inch_NPT_Female.html

Then attach an NPT thermowell to a female QD.

Close the lid, then insert thermowell.

How much for a lid with the male QD welded on?

eta: What about welding an 18" thermowell to a barbed QD female?

http://www.norcalbrewingsolutions.com/store/Quick_Disconnect_Female_to_Half_Inch_Barbed.html

How much for the lid/thermowell combo?

Last edited:

I was hoping to get about a 16" Thermowell or longer and I wasnt sure the lid would be easy to close with this long of a thermowell

I don't have the lid in front of me but if i remember correctly the thermowell can only be about 6-7" long otherwise it contacts the side of the keg when you try to put in the lid in.

You may wish to consider if it really needs to be 16" long. That puts it almost to the bottom of the keg.

Similar threads

- Replies

- 54

- Views

- 3K

- Replies

- 0

- Views

- 321

- Replies

- 7

- Views

- 1K