Hey All...newbie that decided to join to learn from more experienced Home Brewers....

I am trying to follow the thread to make my own cleaning kit and have a 1 gallon pump sprayer at home that I purchased specifically to make this rig. I am having a difficult time trying to figure out what exactly I need because I do not have the ball lock or whatever on my beer line hose. My beer line hose has a threaded nut (that I believe is 7/8) that goes directly in my coupler? Here is a link of what my setup consists of:

Beer line:

http://www.amazon.com/dp/B004SKXW12/?tag=skimlinks_replacement-20

End of beer line attaches directly to keg coupler:

http://www.amazon.com/dp/B00HSI8JP0/?tag=skimlinks_replacement-20

I apologize up front for the novice questions but I really would like to get a cleaning system set up versus taking every piece apart.

Thanks for any assistance you can provide....

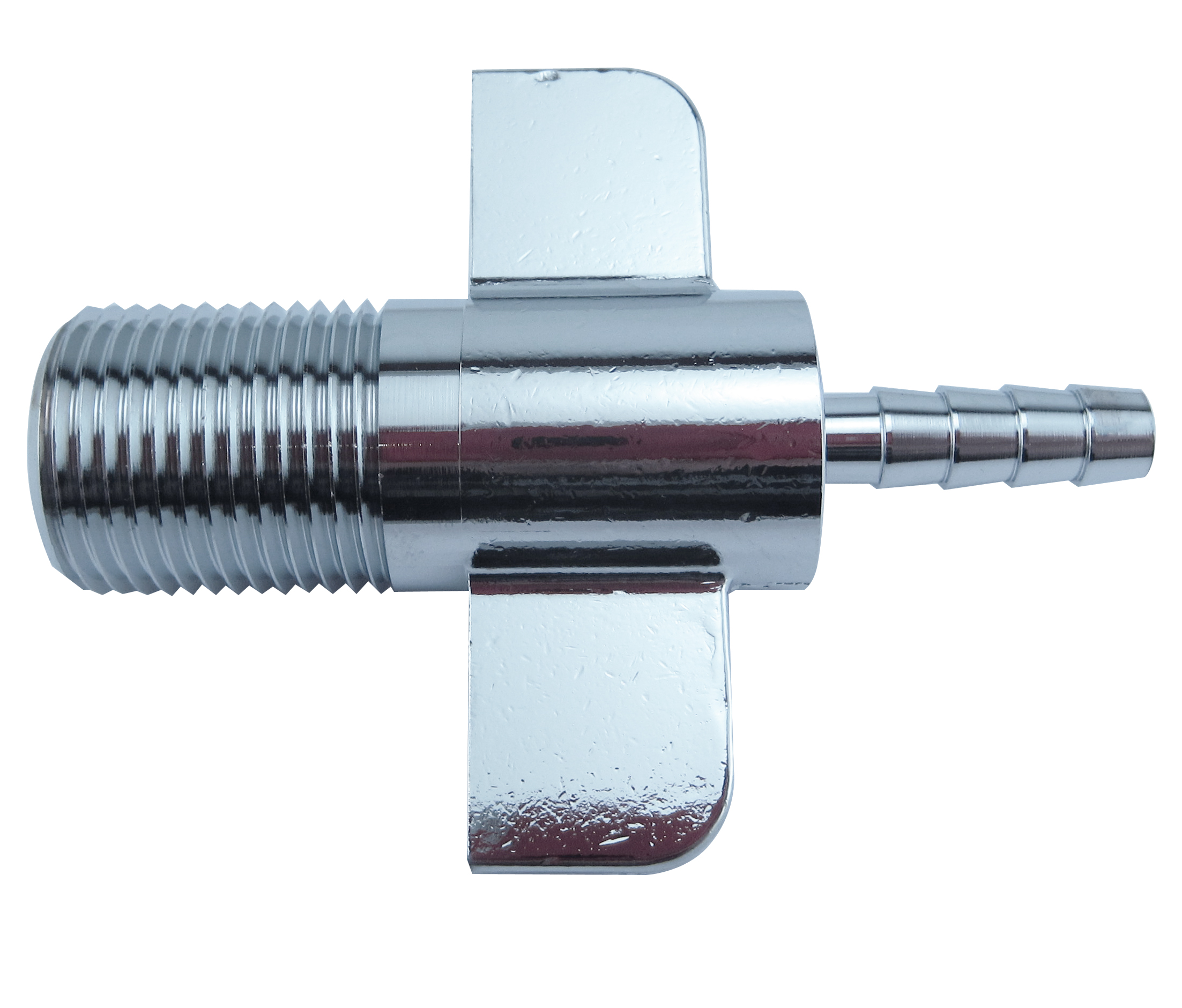

What I found that fit that nut was a pressure washer quick disconnect in the big box stores

View attachment 1459786229317.jpg

Last edited by a moderator: