You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

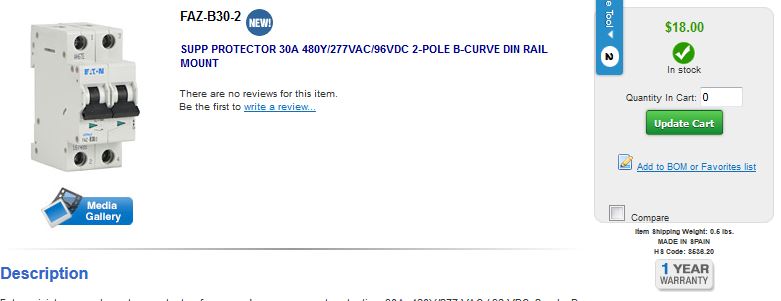

DIN rail breakers

- Thread starter dukes7779

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

if a fuse pops, it needs to be replaced whereas a breaker is simply turned back on. the breakers tend to cost a bit more than the fuses but the cost difference is minimal. really more of a personal preference than anything else.

din rail is a convenient means of mounting components/devices in the panel, as opposed to individually mounting each piece to the back panel.

din rail is a convenient means of mounting components/devices in the panel, as opposed to individually mounting each piece to the back panel.

It also seems that there are more wires involved in the controllers that have breakers. Just my imagination?

no change in wire counts, unless adding breakers that weren't there before. but if you added fuses instead of breakers, same additional wires.

din-mounted fuse blocks are available as well. all the din rail gets you is an easier means of installation.

The10mmKid

Well-Known Member

no change in wire counts, unless adding breakers that weren't there before. but if you added fuses instead of breakers, same additional wires.

din-mounted fuse blocks are available as well. all the din rail gets you is an easier means of installation.

DIN rail means "Snap On -Snap Off"

Changes are Easy Peasy with DIN rail

DIN rail means "Snap On -Snap Off"

Changes are Easy Peasy with DIN rail

+100 on this. Its also easier to move things around within the panel with DIN Rail breakers and components. If you get it all laid out with your original design and realize a breaker or BUS needs to be moved down to accomodate better wiring routing, a DIN rail setup helps big time here.

I know I ran into this with mine which made me glad I choose the DIN Rail option.

They do seem more complex when they chose DIN rails. Anyone have a resource for fuse blocks? All I can find is inline fuse holders that will just flop around.

din rail isn't a requirement, it just makes mounting a greater amount of components easier, when compared to mounting them individually. putting in din rail to mount one component doesn't gain much but makes a big difference if you have to mount, say, 20 items.

below is a link for some din fuses, lots of places sell them:

http://www.omega.com/pptst/ASK_FUSEHOLD.html

The10mmKid

Well-Known Member

Here, maybe this will convince ya':

Wha . . . .what?

Wha . . . .what?

broncosaurs

Well-Known Member

cbarker777

Well-Known Member

- Joined

- May 3, 2015

- Messages

- 52

- Reaction score

- 1

I am looking for a reference on how to use din rail and the different connections anyone have anything? I think because I have not seen din rail I have a hard time seeing how to use it in my head. I have a pretty simple set up power in breaker then pid timer ssr and a single switched outlet. All 120v. Thanks in advance. And sorry to highjack a thread but this was the closest one I could find.

The10mmKid

Well-Known Member

There's a bunch of info on Automation Direct:

http://www.automationdirect.com/adc/Overview/Catalog/Terminal_Blocks/Konnect-It_DIN-Rail_Terminal_Blocks/DIN_Rails,_Clips_-a-_Brackets

http://www.automationdirect.com/adc/Overview/Catalog/Terminal_Blocks/Konnect-It_DIN-Rail_Terminal_Blocks/DIN_Rails,_Clips_-a-_Brackets

cbarker777

Well-Known Member

- Joined

- May 3, 2015

- Messages

- 52

- Reaction score

- 1

Thanks I will check it out.

for the components in a typical brew panel, you'll want the 35 mm rail. aluminum or steel is your choice. you can use the din clips if you like, which allows for easy removal of the entire din rail. most of the time though, the rail gets mounted directly to the back panel.

Just make sure you buy wire ferrules for the din components. Clamping onto bare stranded wire only achieves 50% contact. Ferrules provide 100% contact. The crimpers are not expensive, I bought mine on Amazon for $30.

Clamping onto bare stranded wire only achieves 50% contact.

this is not a true statement, at least not for every and all stranded connections. most terminal blocks have plates or pads underneath the screw connector, such that the flat plate/pad presses against the stranded conductor. the conductor is 'sandwiched' between two flat surfaces and makes an acceptable termination. contrast this to the terminals where the screw itself presses down on the conductor. these are the types susceptible to splayed connections, where not every strand of the stranded conductor ends up underneath the screw.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 3

- Views

- 566