Laphroaig

I Love Scotch. Scotchy, Scotch, Scotch.

Anyone ever attempt it? Ive started tearing into it and there’s some wire, some temp sensors, and temp controls. Just wondering if anyone’s done it and if there’s some examples of what people did with these things.

I’ll consult a wiring diagram soon to see if I can interrupt these controls with my own. But I wanted to get some ideas flowing.

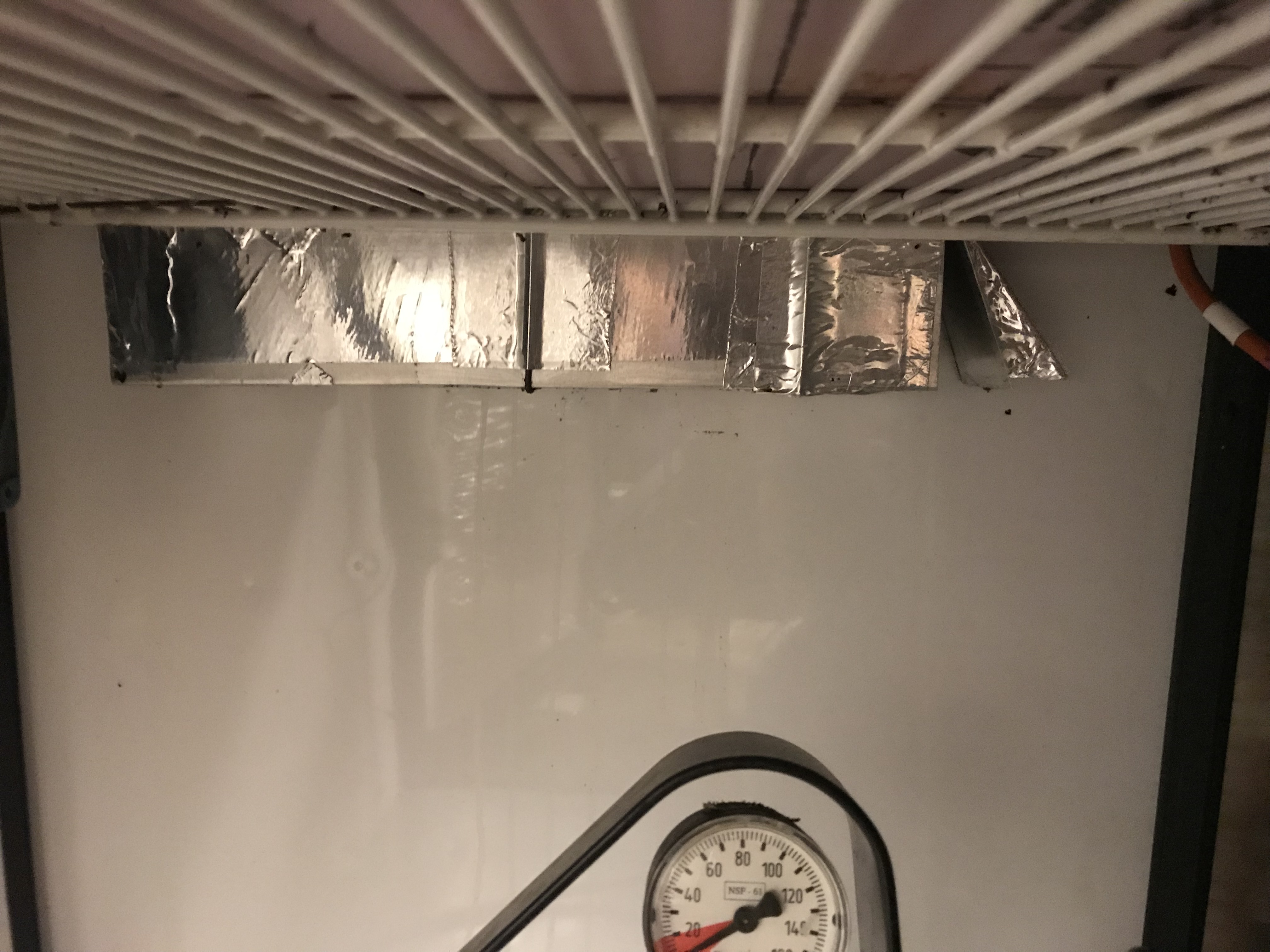

That’s basically all I found. That and a bunch of insulation. If I can delete these things even better!

I’ll consult a wiring diagram soon to see if I can interrupt these controls with my own. But I wanted to get some ideas flowing.

That’s basically all I found. That and a bunch of insulation. If I can delete these things even better!