Hello,

I tried searching for this but there are too many overlapping terms.

I was wondering of anybody has put a pot inside a pot of boiling water to execute a decoction? I heard this on a Brewcaster episode many years ago. The thought is to remove scorching risk by putting a smaller stock pot with the grains inside a boil kettle which would have boiling water bubbling away. The only question is if the grains would actually make it to a boil themselves. Is there enough heat transferred to bring the grain to a boil? This would be for a 5 gallon batch so probably 3 pounds of grain and 2.5 gallons of water.

Just exploring at this point and the approach might have fatal flaws but thought it would be a decent discussion. Thanks.

I tried searching for this but there are too many overlapping terms.

I was wondering of anybody has put a pot inside a pot of boiling water to execute a decoction? I heard this on a Brewcaster episode many years ago. The thought is to remove scorching risk by putting a smaller stock pot with the grains inside a boil kettle which would have boiling water bubbling away. The only question is if the grains would actually make it to a boil themselves. Is there enough heat transferred to bring the grain to a boil? This would be for a 5 gallon batch so probably 3 pounds of grain and 2.5 gallons of water.

Just exploring at this point and the approach might have fatal flaws but thought it would be a decent discussion. Thanks.

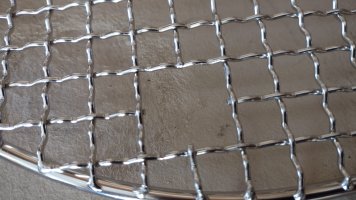

![IMG_20231103_105814198[1].jpg](https://cdn.homebrewtalk.com/data/attachments/773/773714-8cdc80184d4611f1dc7d909151edf20c.jpg)